30

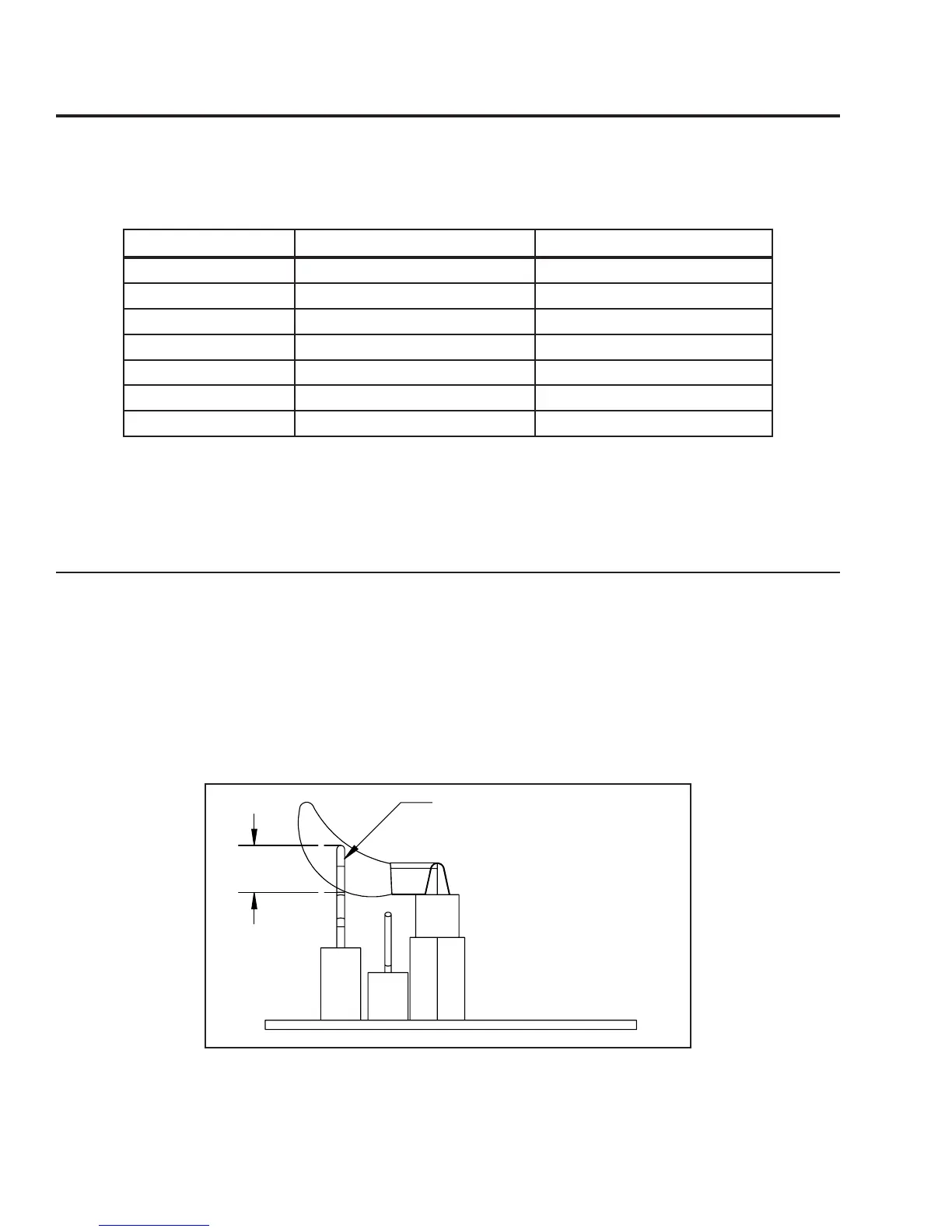

Table 9: Orice and Pressure Information.

EX32 With Log Set & Proame Valve

Main Burner Natural Gas Propane Gas

Orice: #37 DMS #52 DMS

Max. Manifold Press: 3.6 W.C. (0.89 KPa) 10.0” W.C. (2.49 KPa)

Min. Manifold Press: 1.6 W.C. (0.40 KPa) 6.4” W.C. (1.59 KPa)

Max. Supply Press: 7.0” W.C. (1.74 KPa) 11.0” W.C. (2.74 KPa)

Min. Supply Press: 4.5” W.C. (1.12 KPa) 10.4” W.C. (2.59 KPa)

Max. Input: 32,500 BTU/hr (9.52 KW) 31,000 BTU/hr (9.08 KW)

Min. Input: 21,000 BTU/hr (6.15 KW) 24,500 BTU/hr (7.18 KW)

NEVER USE AN OPEN FLAME FOR LEAK TESTING.

aDjusting the piLot fLame:

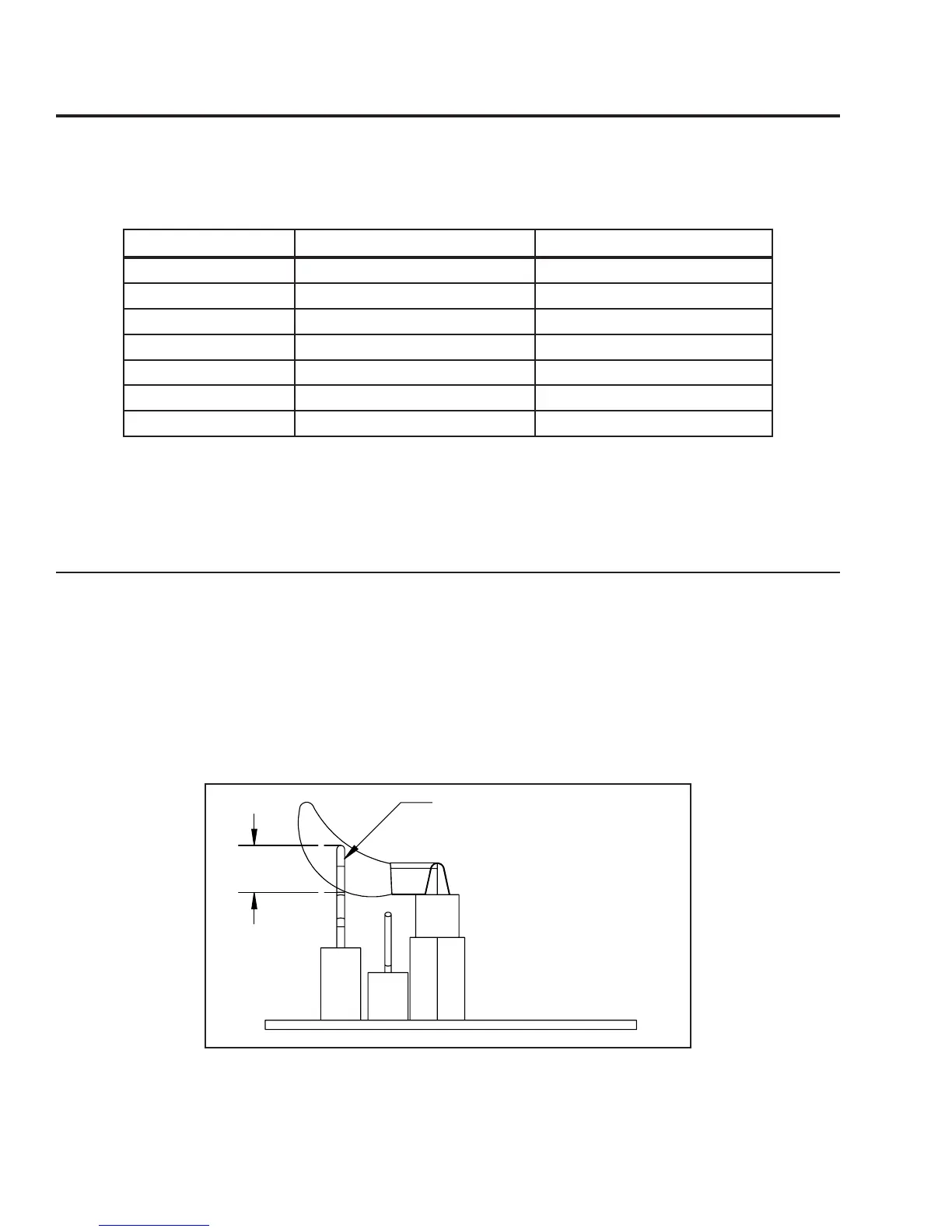

The pilot ow adjustment is set to maximum at the factory and should not need to be adjusted. The pilot

ame should envelope ⅜” to ½” (10 to 13mm) of the Flame sensor (see Figure 35). However, should the

need arise, follow Steps 1- 2 below.

1. The adjustment screw can be reached through the front of the unit using a 10 inch long blade head

screw driver (see Figure 34 for location on valve).

2. Turn the adjustment screw clockwise to decrease or counterclockwise to increase pilot ame.

Figure 35: Proper Pilot Flame.

Initial Installation

QUALIFIED INSTALLERS ONLY

.375

-.500

(10-13mm)

Flame Sensor

Loading...

Loading...