6

ENVISION RESIDENTIAL INSTALLATION MANUAL

Duct System

An air outlet collar is provided on vertical top air discharge units and all horizontal units to facilitate a duct connection

(verticalbottomowunitshavenocollar).Aexibleconnectorisrecommendedfordischargeandreturnairductconnec-

tionsonmetalductsystems.Uninsulatedductshouldbeinsulatedwithaminimumof1-inchductinsulation.Applicationof

the unit to uninsulated ductwork in an unconditioned space is not recommended as the unit’s performance will be adversely

affected.

If the unit is connected to existing ductwork, check the duct system to ensure that it has the capacity to accommodate

the air required for the unit application. If the duct is too small, as in the replacement of heating only systems, larger duct-

work should be installed. All existing ductwork should be checked for leaks and repaired if necessary.

Theductsystemshouldbesizedtohandlethedesignairowquietlyandefciently.Tomaximizesoundattenuationof

theunitblower,thesupplyandreturnplenumsshouldincludeaninternalductlinerofberglassorconstructedofductboard

fortherstfewfeet.Onsystemsemployingasheetmetalductsystem,canvasconnectorsshouldbeusedbetweenthe

unitandtheductwork.Ifairnoiseorexcessiveairowisaproblem,theblowerspeedcanbechanged.

Water Piping

Theproperwaterowmustbeprovidedtoeachunitwheneverthe

unitoperates.Toassureproperow,usepressure/temperatureports

todeterminetheowrate.Theseportsshouldbelocatedatthesupply

andreturnwaterconnectionsontheunit.Theproperowratecannot

be accurately set without measuring the water pressure drop through

the refrigerant-to-water heat exchanger.

Allsourcewaterconnectionsoncommercialunitsarettingsthat

accept a male pipe thread (MPT). Insert the connectors by hand, then

tightenthettingwithawrenchtoprovidealeakproofjoint.Whencon-

necting to an open loop (groundwater) system, thread any copper MPT

ttingintotheconnectorandtighteninthesamemannerasdescribed

above.

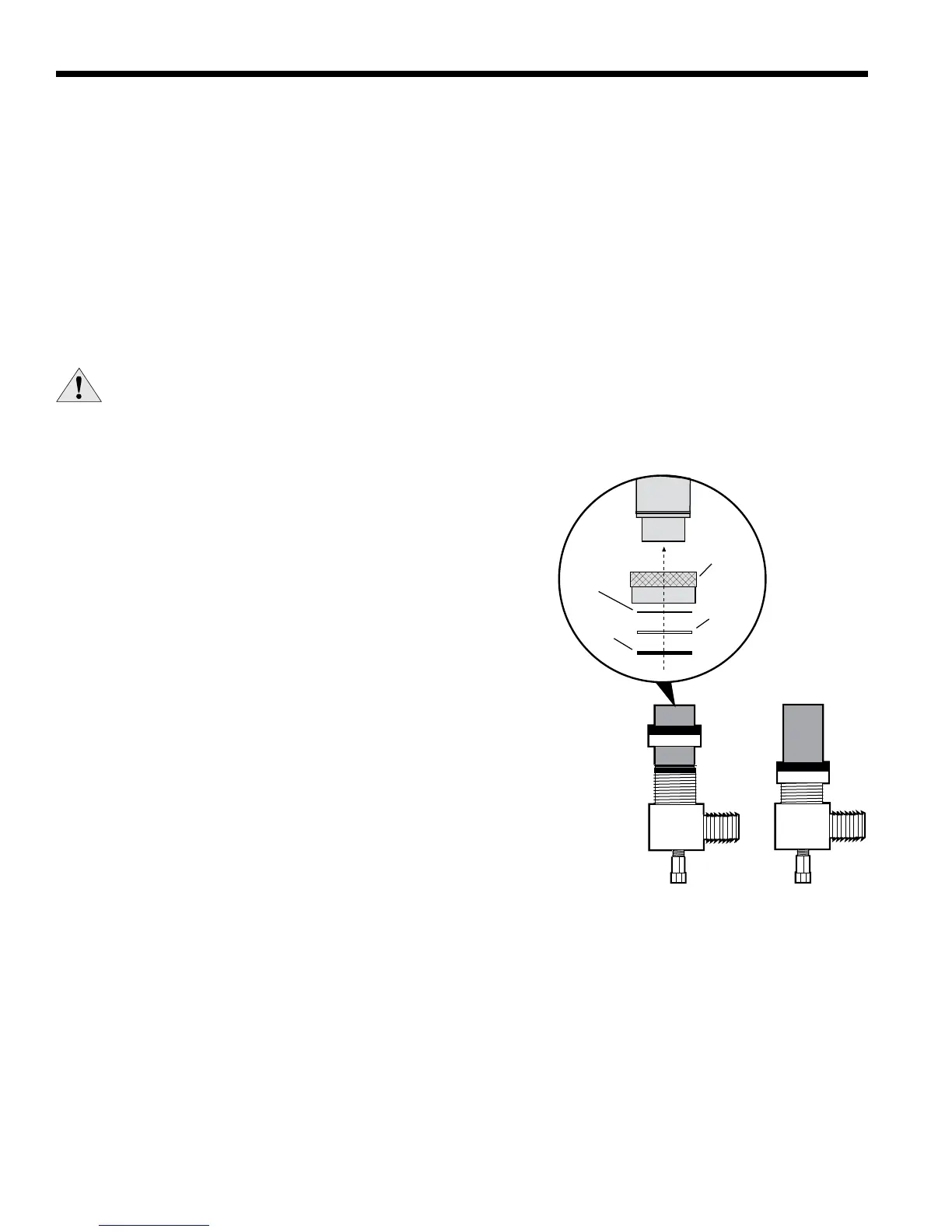

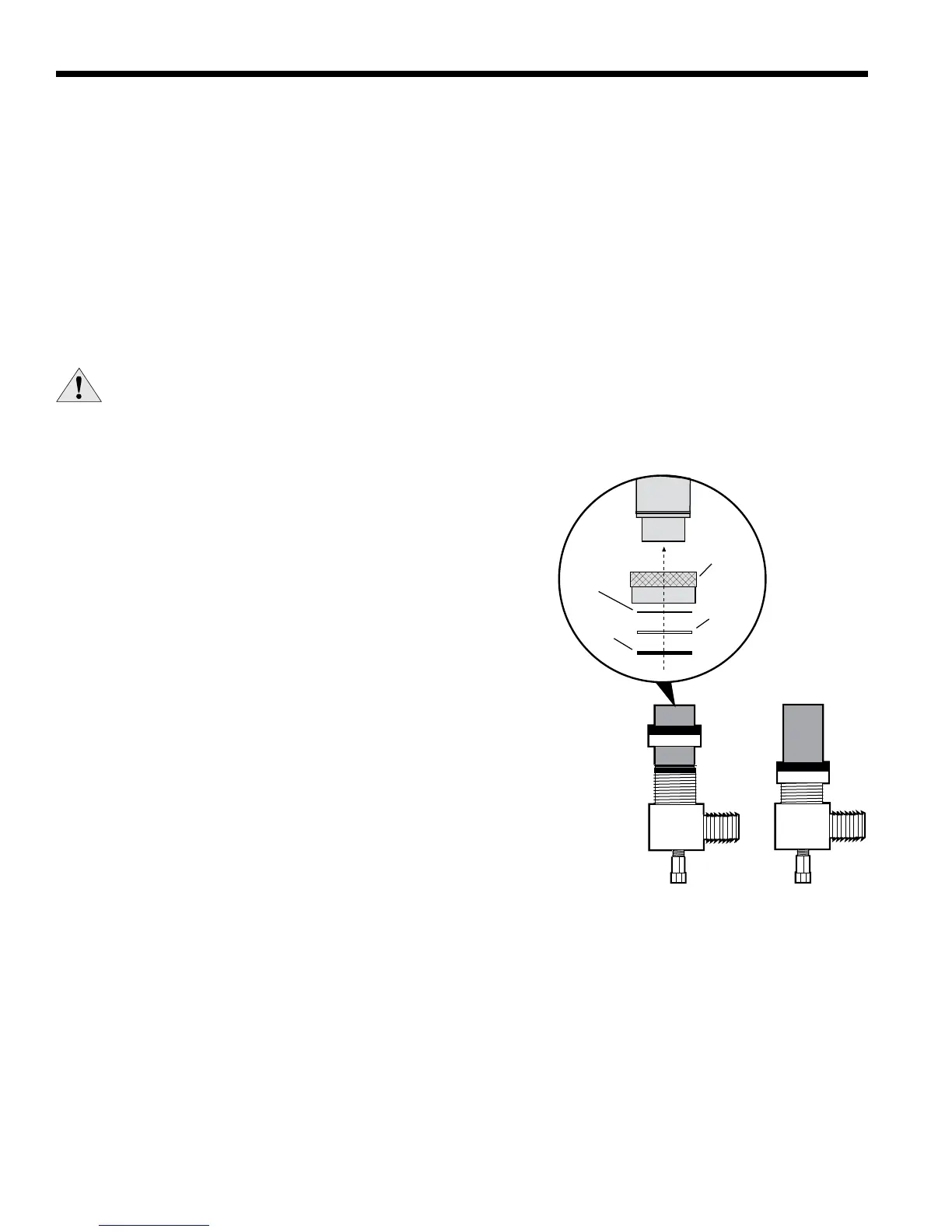

All source water connections on residential units are swivel piping

ttings(seeFigure4)thataccepta1-inchmalepipethread(MPT).

The swivel connector has a rubber gasket seal similar to a rubber hose

gasket,whichwhenmatedtotheushendofany1-inchthreaded

pipe provides a leak-free seal without the need for thread sealing tape

or compound. Check to ensure that the rubber seal is in the swivel

connector prior to attempting any connection. The rubber seals are

shipped attached to the waterline. To make the connection to a ground

loopsystem,matethebrassconnector(suppliedinCK4Lconnectorkit)

against the rubber gasket in the swivel connector and thread the female

locking ring onto the pipe threads, while maintaining the brass connec-

tor in the desired direction. Tighten the connectors by hand, then gently

snugthettingwithplierstoprovidealeak-proofjoint.Whenconnectingtoanopenloop(groundwater)system,threadany

1-inchMPTtting(SCH80PVCorcopper)intotheswivelconnectorandtighteninthesamemannerasnotedabove.The

openandclosedlooppipingsystemshouldincludepressure/temperaturetapsforserviceability.

Neveruseexiblehosessmallerthan1-inchinsidediameterontheunit.Limithoselengthto10feetperconnection.

Check carefully for water leaks.

Figure 4: Swivel Connections

(Residential Units)

Locking

Ring

Stainless

Steel

Snap Ring

Gasket

Support

Sleeve

Gasket

Material

CAUTION: Be sure to remove the shipping material from the blower discharge before con-

necting ductwork.

Loading...

Loading...