BURNER INSTALLATION

Electrical Connection

The electrical connections to this burner must be

carried out by a suitably qualified engineer.

All Electrical connections to the burner must be

carried out in accordance with all current

applicable IEE Wiring Regulations.

All connections should be made according to the

wring diagram shown on the supplementary page -

page 20 within the manual.

If the burner is fitted with a 7-pin socket and

supplied with the matching plug then all

connections therefore are made within the 7-pin

plug.

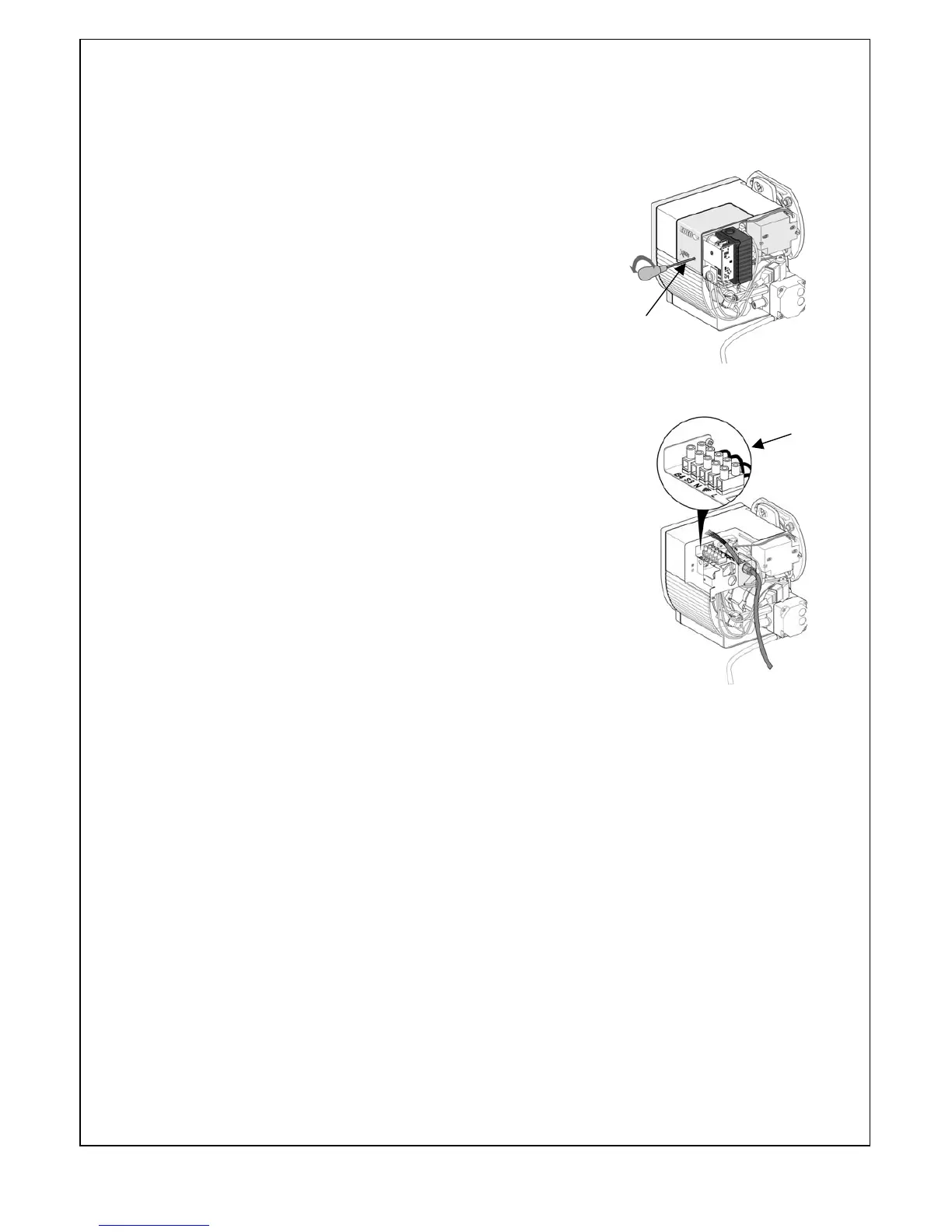

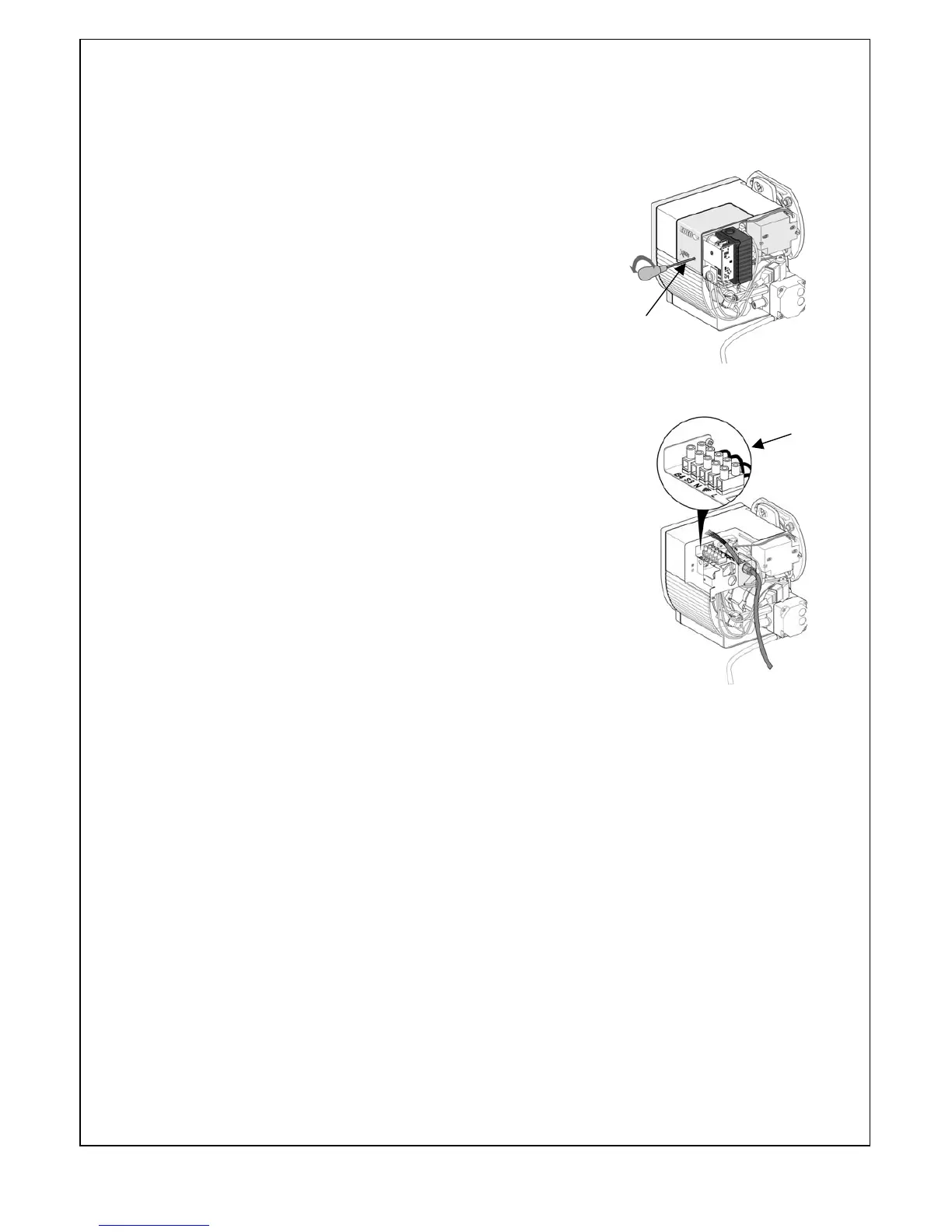

To gain access to the electrical connection strip the

cover must be removed by means of undoing the

3mm Allen screw. Once undone the cover can be

removed exposing the connection strip.

Fuel Supply

The burner is usually supplied for one-pipe operation

but if required can be converted for a two-pipe system (see page 10 for

details). When used in conjunction with a gravity feed supply the inlet pressure

to the pump MUST NOT exceed 2 bar.

When using a two-pipe system the return line has to be fed back into the

tank. Alternatively, a de-aeration device could be incorporated for ease of

installation.

Oil lines must be completely air-tight and constructed in accordance with

current standards.

The final connection to the oil pump must be made with the flexible oil line

provided.

Air Supply

Combustion air and ventilation requirements are detailed in BS5410:Part1. It

requires that combustion air must be provided through purpose-made non-

closeable openings, having a total free area of 550mm2 per kW of the

appliance maximum output rating above 5kW.

Cover fixing

Loading...

Loading...