Maintenance 6. Joint #2

LS20-B Rev.4 107

the cross roller bearing to

.

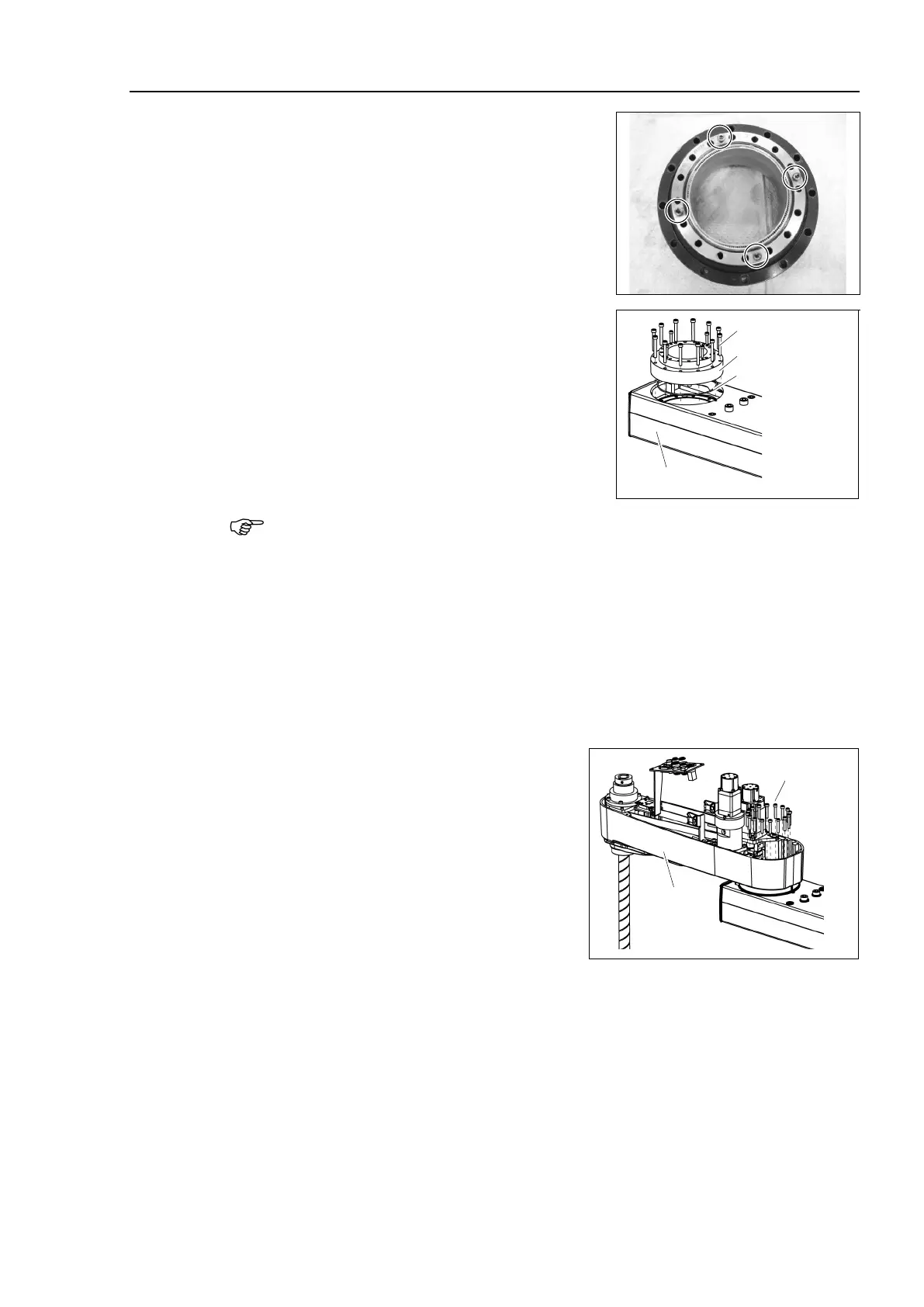

4-M4×20

Tightening torque: 4.0 N·m (40.8 kgf·cm)

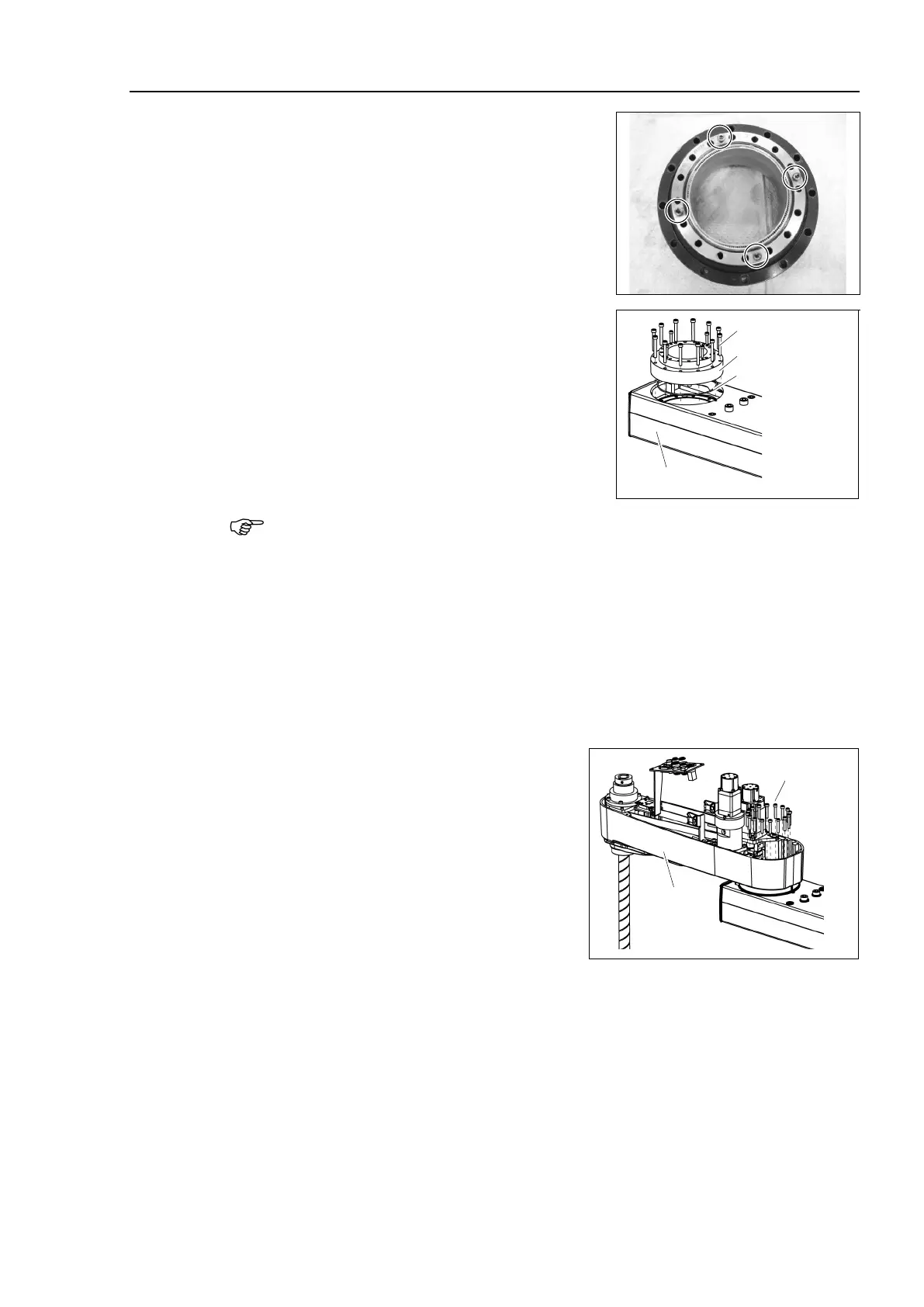

Set the O-ring removed in the removal step (6)

into the O-ring groove of the Arm #1.

Install the reduction gear unit on the Arm #1.

Hexagon socket head cap bolts: 12-M5×40

Tightening torque: 10.0 N⋅m (102 kgf⋅cm)

Arm #1

12-M5×40

Reduction Gear

Unit

O-ring

Loosely secure all bolts in a crisscross pattern so that the bolts will be secured evenly.

Then, using a torque wrench, tighten each bolt securely in a crisscross pattern at the

torque specified in the

above.

Apply grease between the motor flange an

d waveform generator and next inside the

Between the motor flange and waveform generator:

Grease volume: 38 g (SK-1A)

Inside the flexspline:

Grease volume: 90 g (SK-1A)

Set the attached O-ring into the O-ring

groove of the circular spline.

Secure the Arm #2 on the reduction gear

unit.

Mount and Joint #2 motor.

Follow the installation steps in Maintenance: 6.1 Replacing Joint #2 Motor.

Loading...

Loading...