2. Installation

RC180 Safety and Installation Rev.18

42

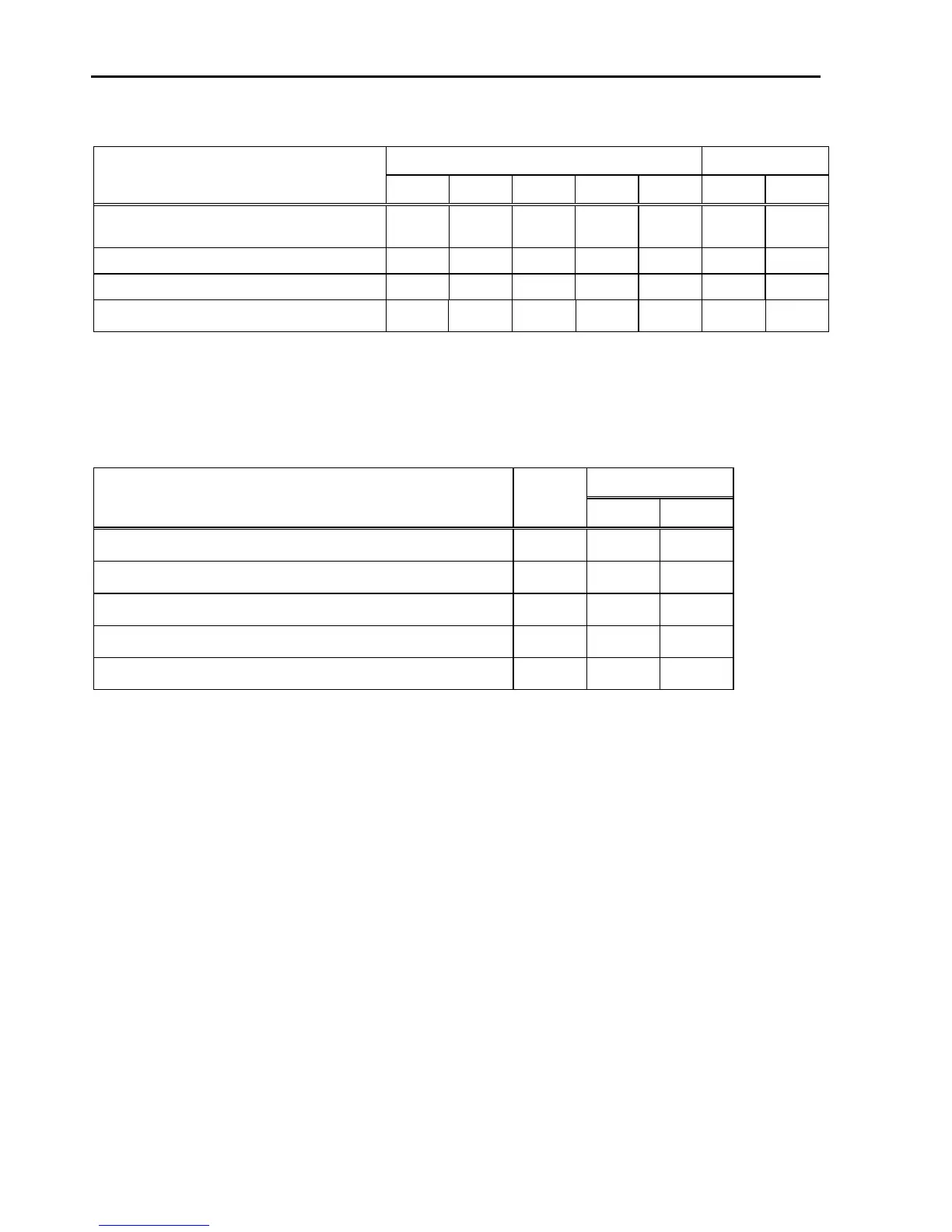

G / RS series

G

RS

G1

G3 G6 G10

G20

RS3 RS4

Max. Reaction torque on the

horizontal plate (Nm)

100 300 500 1000 1000 500 500

Max. Horizontal reaction force (N)

200 2000 2500 4500 7500 1200 1400

Max. Vertical reaction force (N)

300 1000 1500 2000 2000 1100 1100

Threaded holes for Mounting screw

M6 M8 M8 M12 M12 M6 M6

The plate for the Manipulator mounting face should be 20 mm thick or more and

made of steel to reduce vibration. The surface roughness of the steel plate should

be 25 μm or less.

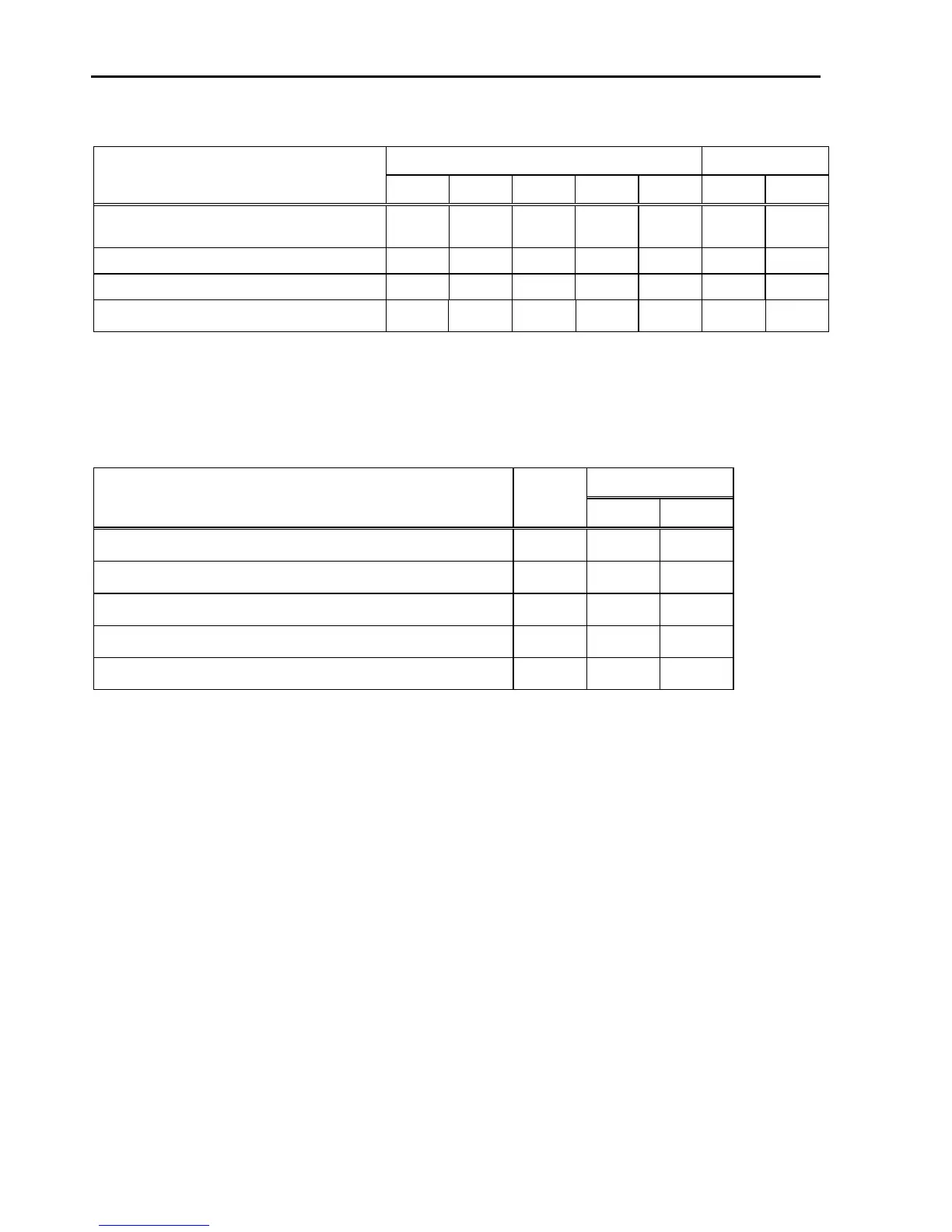

C3 / S5 series

S5

C3

701 901

Max. Reaction torque on the horizontal plate (Nm)

500 600 900

Max. Horizontal reaction force (N)

800 1000 1400

Max. Reaction torque on the vertical plate (Nm)

600 800 900

Max. Vertical reaction force (N)

2500 3000 3500

Threaded holes for Mounting screw M8 M10 M10

The plate for the Manipulator mounting face should be 30 mm thick or more and

made of steel to reduce vibration. The surface roughness of the steel plate should

be 25 μm or less.

Use mounting bolts with specifications conforming to ISO898-1 property class:

10.9 or 12.9.

The table must be secured on the floor or wall to prevent it from moving.

The Manipulator must be installed horizontally.

When using a leveler to adjust the height of the base table, use a screw with M16

diameter

Loading...

Loading...