SC-P600 Revision D

Adjustment Required Adjustments 37

SE Group Confidential (Related Staff Only)

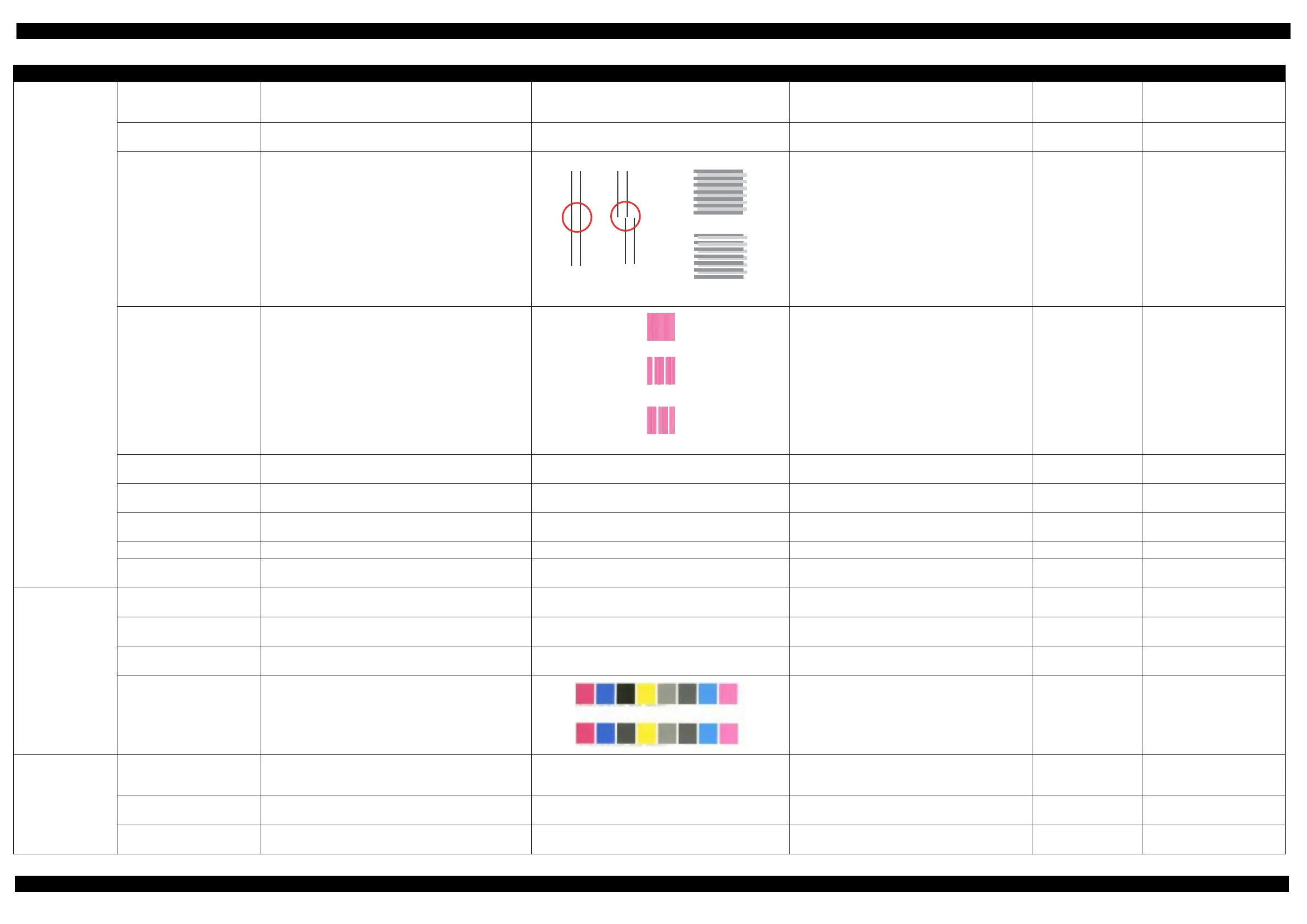

Print Head / CR related

PG Adjustment

To secure the specified clearance between the print surface of the

Printhead and paper, and adjust the parallelism of the 0-digit and

130-digit sides in order to maintain the print quality.

--- See " 2.3.4 PG Adjustment (p49)" for the details. --- Adjustment gauge

Head ID Input

To correct characteristic variation of the replaced Printhead by

entering its Printhead ID (Head ID).

--- --- O ---

Head angular adjustment CR / PF

To correct the head angular (in CR/PF direction) when installing

the Printhead.

See " 2.3.7 Head Angular Adjustment CR/PF (p55)" for the

details.

O---

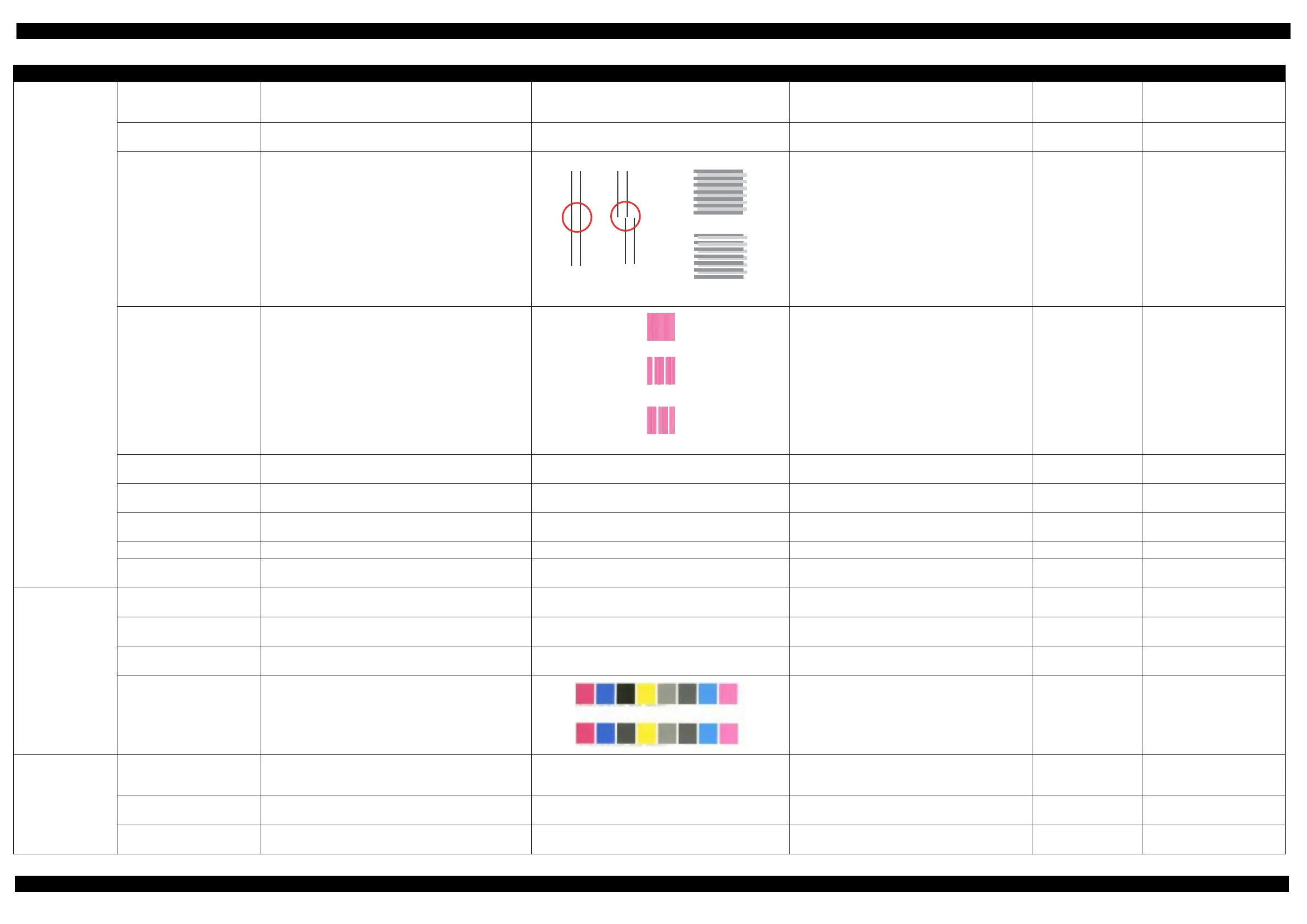

Bi-D adjustment

To correct print start timing in bidirectional printing through

software control.

Examine the printout patterns, and enter the value for the

pattern with no gap and overlap.

O---

CR motor heat protection control

To measure and correct the electrical variation of the motor and

the power supply board.

--- --- O ---

Colorimetric calibration

To register the Color ID to ensure consistent color quality.

---

See " 2.3.8 Colorimetric Calibration (p57)" for the details.

---

See " 2.3.8 Colorimetric

Calibration (p57)" for the details.

APG Function check

To rotates the APG motor to change the PG, and see if the PG is

correctly set to its home position.

--- --- O ---

CR Belt check To move the CR Unit, and check if the movement is correctly. --- --- O ---

CR encoder check

To check the CR Scale for any abnormality such as damage or dirt

and check if the scale can be properly read by the encoder

--- --- O ---

Ink Supply related

Mist Recovery check

To confirm the voltage applied to the plate under the Front Paper

Guide Assy is proper for ink mist recovery inside the printer.

--- See " 2.3.5 Mist Recovery check (p53)" for the details. O ---

Waste Ink Pad Counter

To reset the waste ink counter after replacing the Waste Ink

Pad.*1

--- --- O ---

Ink charge

To fill ink inside the new Printhead to make it ready for print after

replacing the Printhead.*2

--- --- O ---

Ink Selector Check To check the operation of the ink selector correctly. See " 2.3.9 Ink Selector Check (p69)" for the details. O ---

Boards related

EEPROM Data Copy

To copy adjustment values or the like stored on the old Main

Board to the new board when the Main Board needs to be

replaced.

--- --- O ---

Initialize Setting

To write sales-destination-specific settings and the serial number

into the Main Board after replacing it.

--- --- O ---

MAC address Input

To input the MAC address if the data in EEPROM cannot be read

out.

--- See " 2.3.6 Initial setting (p54)" for the details. O ---

Table 2-3. Adjustment Items

Class Adjustment Items Purpose Printout pattern Hoe to judge Service Program Tool

NGOK

Loading...

Loading...