41

SECTION 4 OPERATION

4.4.1.3 Surface roughness:

Excellent - Bright and smooth•

Good - Discolored, fairly smooth•

Fair - Moderate roughness•

Poor - Very rough•

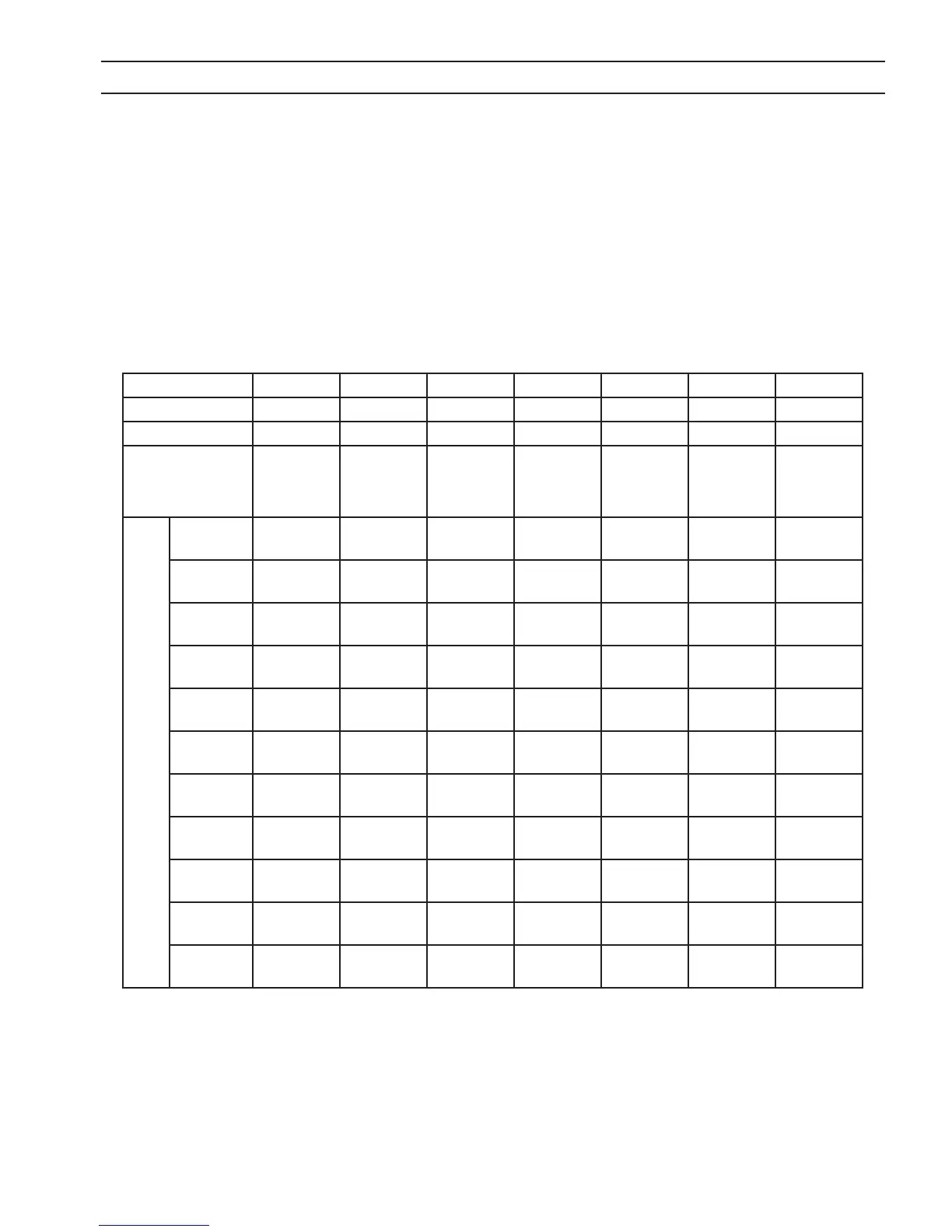

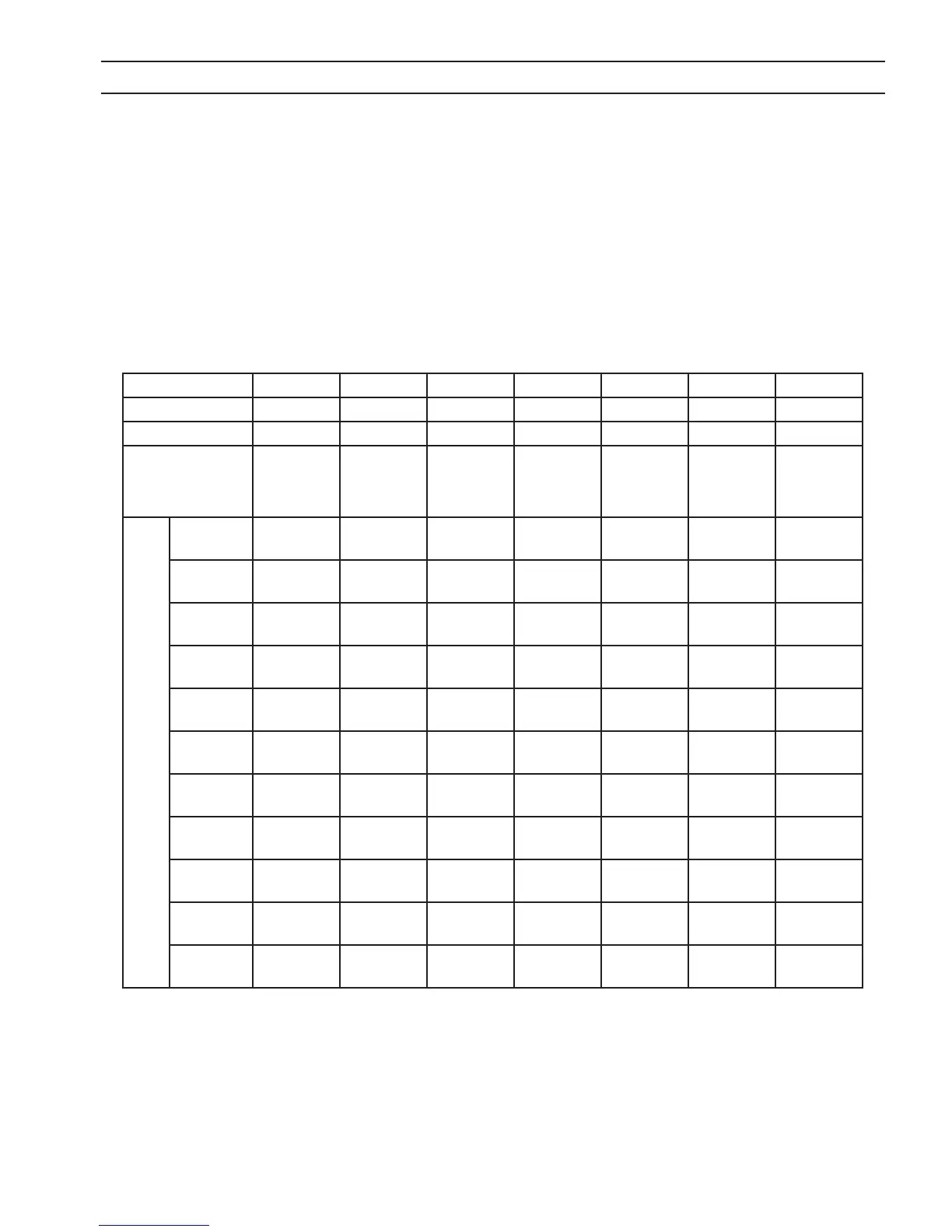

4.4.2 CONDITION SELECTION Charts for PT-19XLS with ESP-200

4.4.2.1 Carbon Steel

Current 50-65A 100A 100A 150A 150A 200A 200A

Plasma gas AIR AIR O

2

AIR O

2

AIR O

2

Shield gas AIR AIR AIR AIR AIR AIR AIR

Dross

Angle

Surface

Dross

Angle

Surface

Dross

Angle

Surface

Dross

Angle

Surface

Dross

Angle

Surface

Dross

Angle

Surface

Dross

Angle

Surface

Material Thickness

1,6mm

(1/16 in.)

G 1 G

3,2mm

(1/8 in.)

G 1 G

6,4mm

(1/4 in.)

G 2 F E 2 G E 1 E E 1 G E 2 E E 3 G E 3 E

9,6mm

(3/8 in.)

E 2 G E 1 E G 2 G E 2 E E 3 G G 3 E

12,7mm

(1/2 in.)

F 1 G E 1 E G 1 G E 1 E G 3 G E 2 E

19,1mm

(3/4 in.)

F 1 G F 1 E F 2 G F 1 E G 2 G E 1 E

25 ,4 mm

(1 in.)

F 1 G G 1 E

31,8mm

(1-1/4 in.)

F 1 G F 1 E

38,1mm

(1-1/2 in.)

F 1 G F 1 E

44,5mm

(1-3/4 in.)

F 1 G F 1 G

50,8mm

(2 in.)

F 1 G F 2 G

Loading...

Loading...