39

SECTION 4 OPERATION

1. Apply power by closing the line (wall) switch. Main power light

will not illuminate until console power switch is turned ON. Fault

light should ash and go out.

2. Select the Panel/Remote setting. If current is controlled from

cutting machine CNC, place switch to Remote position. Consult

cutting machine instructions for current setting. If current is not

controlled by the CNC, select Panel and set current on output

current dial.

3. Check coolant level. Level must be checked with console main

power in OFF position. Coolant level must fall in the safe operat-

ing level.

4. Set pilot arc High/Low switch. (Refer to cutting process data of

the torch manual.)

5. Turn on console power by placing power switch in ON position.

White light to left of the switch will illuminate.

6. Check coolant pressure. The pressure is factory set between 80

to 90 PSI (5.5 –6.2 bars).

7. Begin plasma cutting operation. This may include manually set-

ting other options, depending on total plasma package.

If using panel mode, after cutting has begun, adjust current to de-

sired amount.

Check for a fault light. If a fault light illuminates, SHUT OFF POWER

IMMEDIATELY and refer to troubleshooting section.

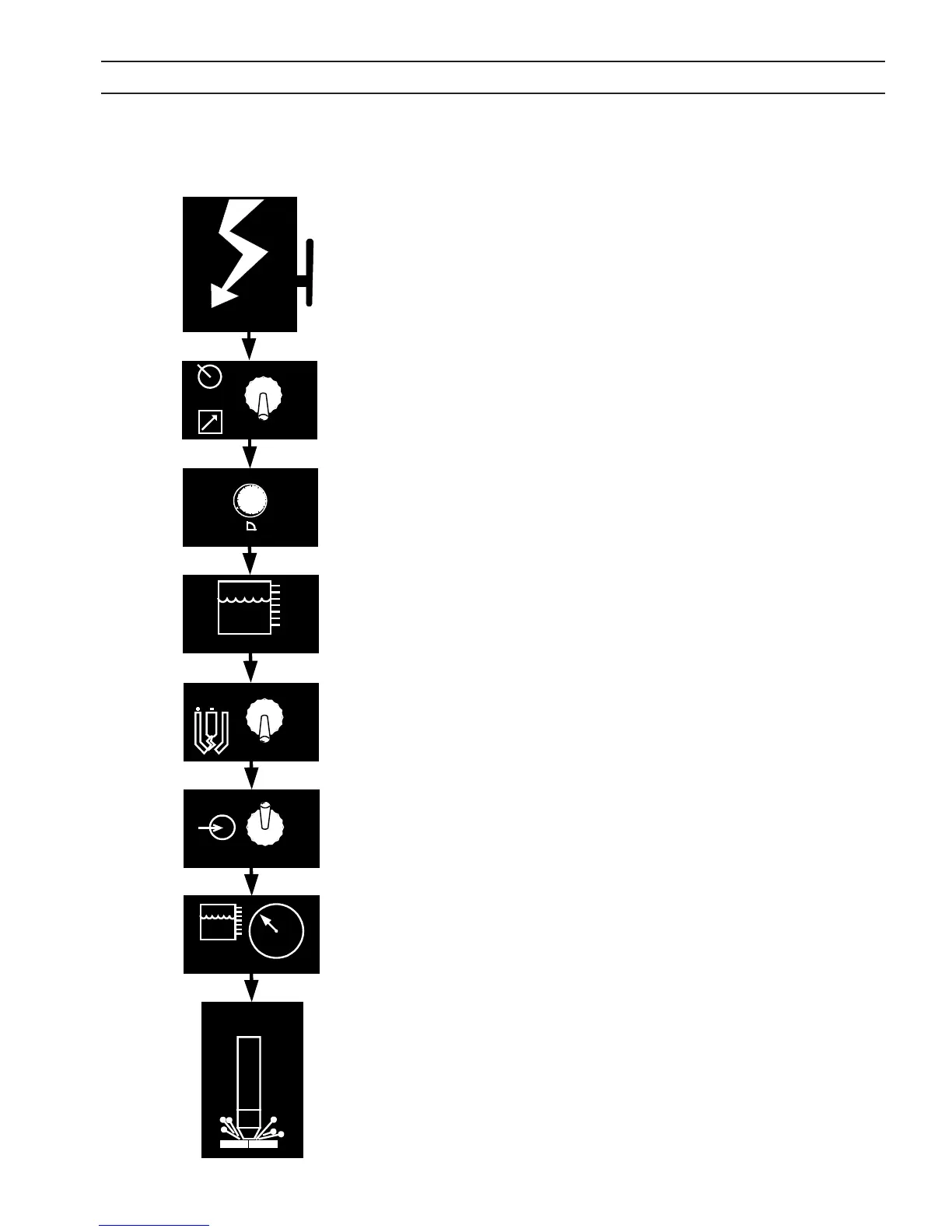

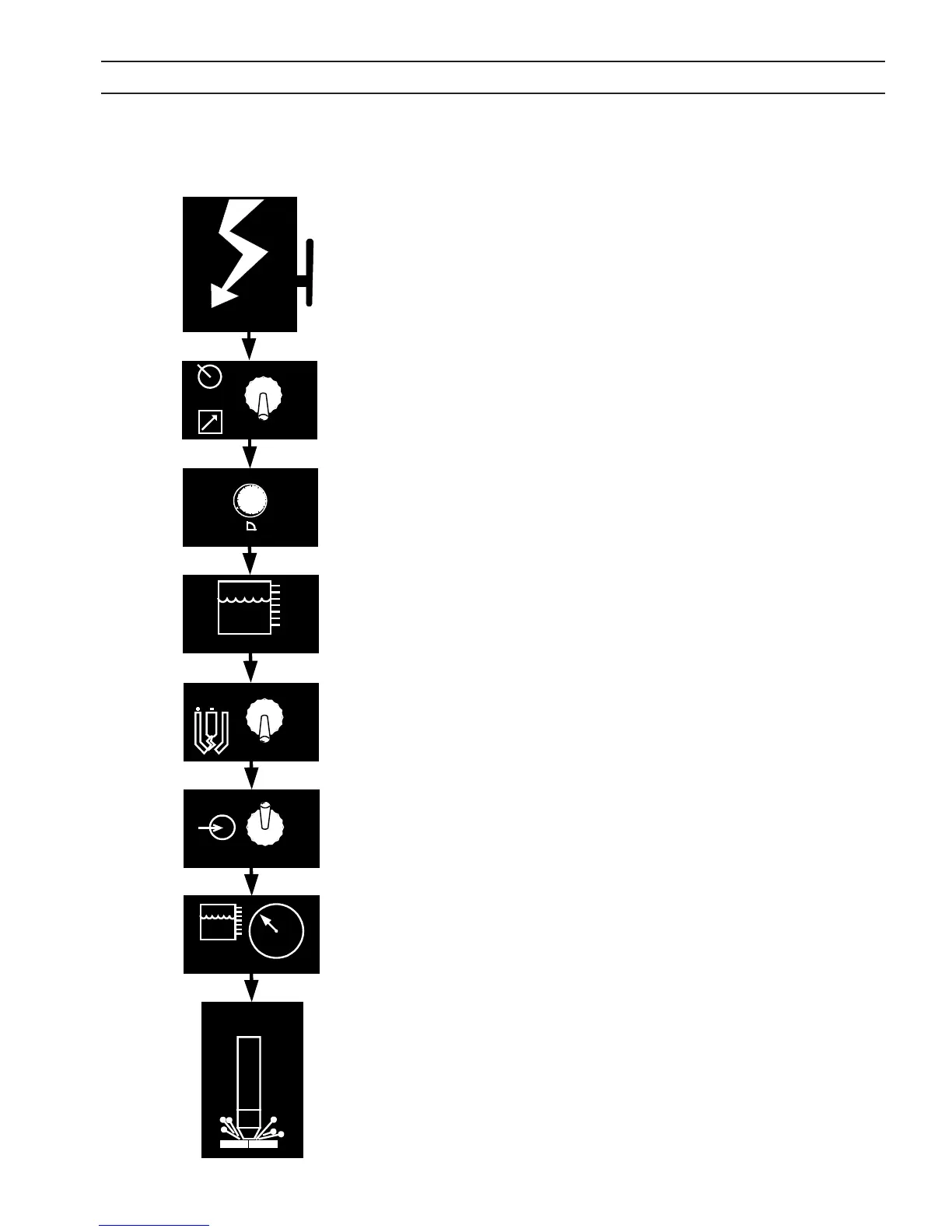

4.3 Sequence of Operation

HIGH

LOW

PILOT

ARC

PANEL

REMOTE

Apply Power

OFF

0

1

2

3

4

5

6

7

8

9

10

CURRENT

Coolant Level

ON

V

POWER

OFF

PSI

Coolant

Begin Cutting

Loading...

Loading...