55

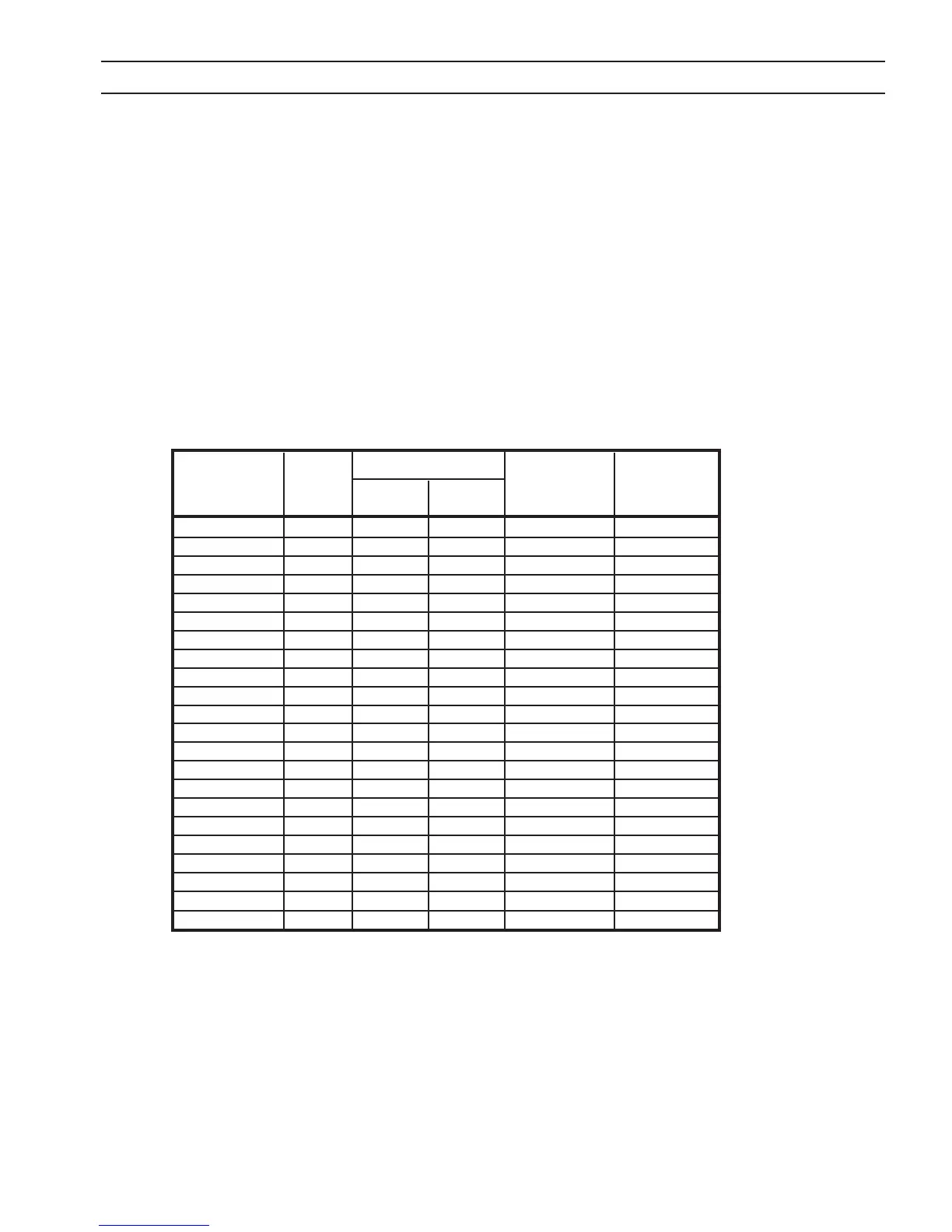

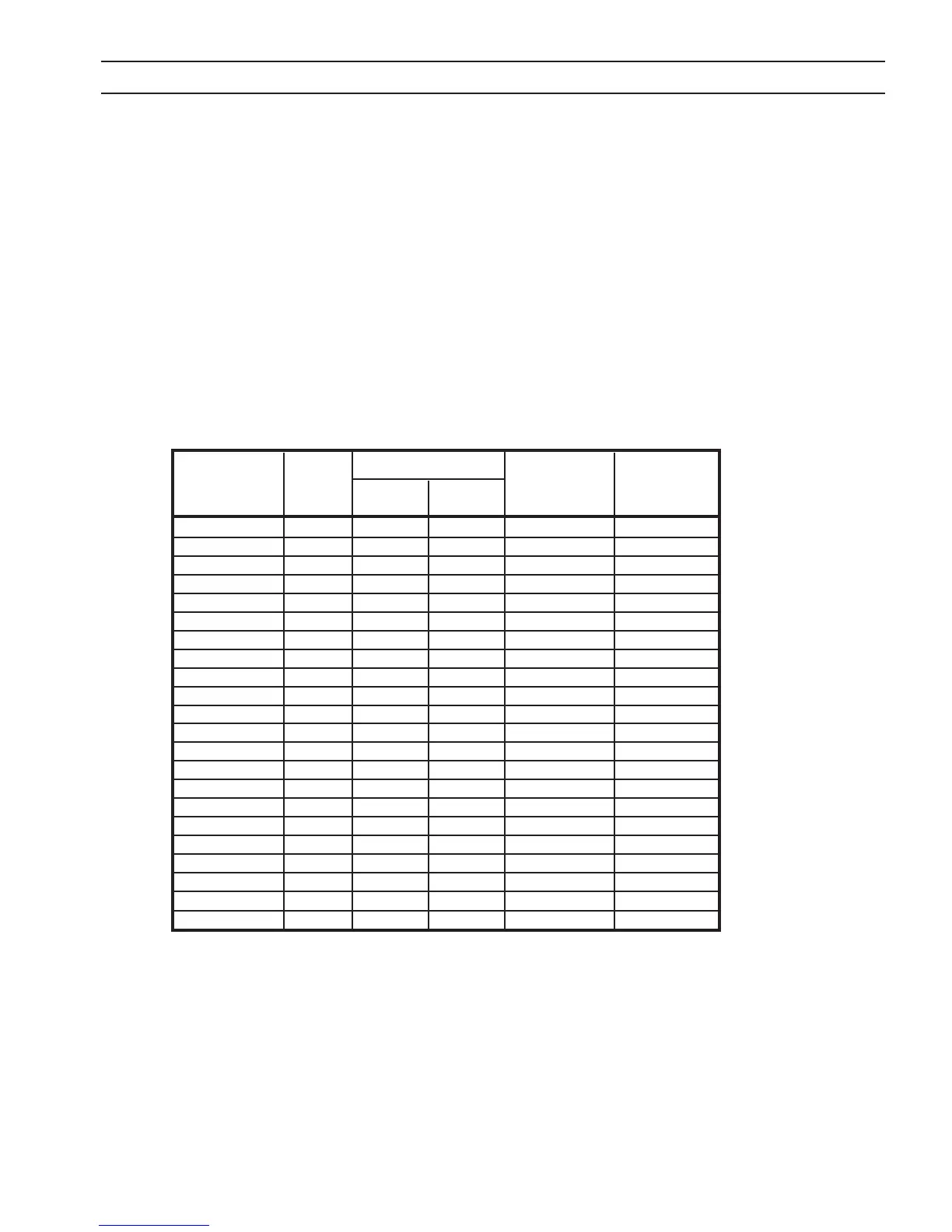

CS - 6,4 (1/4) 5,1 (200) 9,6 (3/8) 9,6 (3/8) 153 4,48 (65)

CS - 9,6 (3/8) 3,17 (125) 9,6 (3/8) 9,6 (3/8) 161 4,48 (65)

CS - 12,7 (1/2) 3,4 (95) 9,6 (3/8) 9,6 (3/8) 163 4,48 (65)

CS – 19,1 (3/4) 1,65 (65) 12,7 (1/2) 6,4 (1/4) 165 4,48 (65)

CS - 25,4 (1.0) 0,89 (35) 12,7 (1/2) 9,6 (3/8) 180 4,48 (65)

CS - 31,7 (1-1/4) 0,64 (25) NR 9,6 (3/8) 182 2,07 (30)

CS – 38,1 (1-1/2) 0,38 (15) NR 9,6 (3/8) 189 2,07 (30)

CS - 50,8 (2.0) 0,15 (6) NR 9,6 (3/8) 211 2,07 (30)

SS - 6,4 (1/4) 5,33 (210) 9,6 (3/8) 9,6 (3/8) 164 4,48 (65)

SS - 9,6 (3/8) 3,94 (155) 9,6 (3/8) 9,6 (3/8) 166 4,48 (65)

SS - 12,7 (1/2) 2,8 (110) 9,6 (3/8) 9,6 (3/8) 170 4,48 (65)

SS – 19,1 (3/4) 1,4 (55) 12,7 (1/2) 9,6 (3/8) 174 4,48 (65)

SS - 25,4 (1.0) 0,64 (25) 12,7 (1/2) 9,6 (3/8) 181 4,48 (65)

SS - 31,7 (1-1/4) 0,38 (15) NR 9,6 (3/8) 187 2,07 (30)

SS – 38,1 (1-1/2) 0,25 (10) NR 9,6 (3/8) 194 2,07 (30)

AL - 6,4 (1/4) 5,33 (210) 9,6 (3/8) 9,6 (3/8) 171 5,86 (85)

AL - 9,6 (3/8) 3,94 (155) 9,6 (3/8) 9,6 (3/8) 179 4,48 (65)

AL - 12,7 (1/2) 2,8 (110) 9,6 (3/8) 9,6 (3/8) 182 4,48 (65)

AL – 19,1 (3/4) 1,65 (65) 9,6 (3/8) 9,6 (3/8) 187 4,48 (65)

AL - 25,4 (1.0) 1,0 (40) 9,6 (3/8) 9,6 (3/8) 189 5,86 (85)

AL - 31,7 (1-1/4) 0,50 (20) NR 9,6 (3/8) 193 2,07 (30)

AL – 38,1 (1-1/2) 0,35 (14) NR 9,6 (3/8) 197 2,07 (30)

SECTION 4 OPERATION

4.4.6 Maximum Economy Conditions

The conditions outlined in the following tables will minimize the operating cost for common metals:

• UseAIRasPLASMAandSHIELDGAS.

• Achievemaximumcuttingspeedwithoutregardtocutquality.

Pilot Arc - HIGH

Current - 200 Amps

Start Gas - AIR @ 25 psig

Plasma Gas - Air @ 45 psig (3.1 bar) for CS, 50 psig (3.5 bar) for SS & Al

Shield Gas - AIR (See Table)

See Torch manual for appropriate consumable part numbers.

Material

Type-Thickness

in.(mm)

Speed

ipm(M/m

Shield Air

psi(bar)

Piercing

in.(mm)

Arc

Voltage

Stando

Cutting

in.(mm)

Loading...

Loading...