75

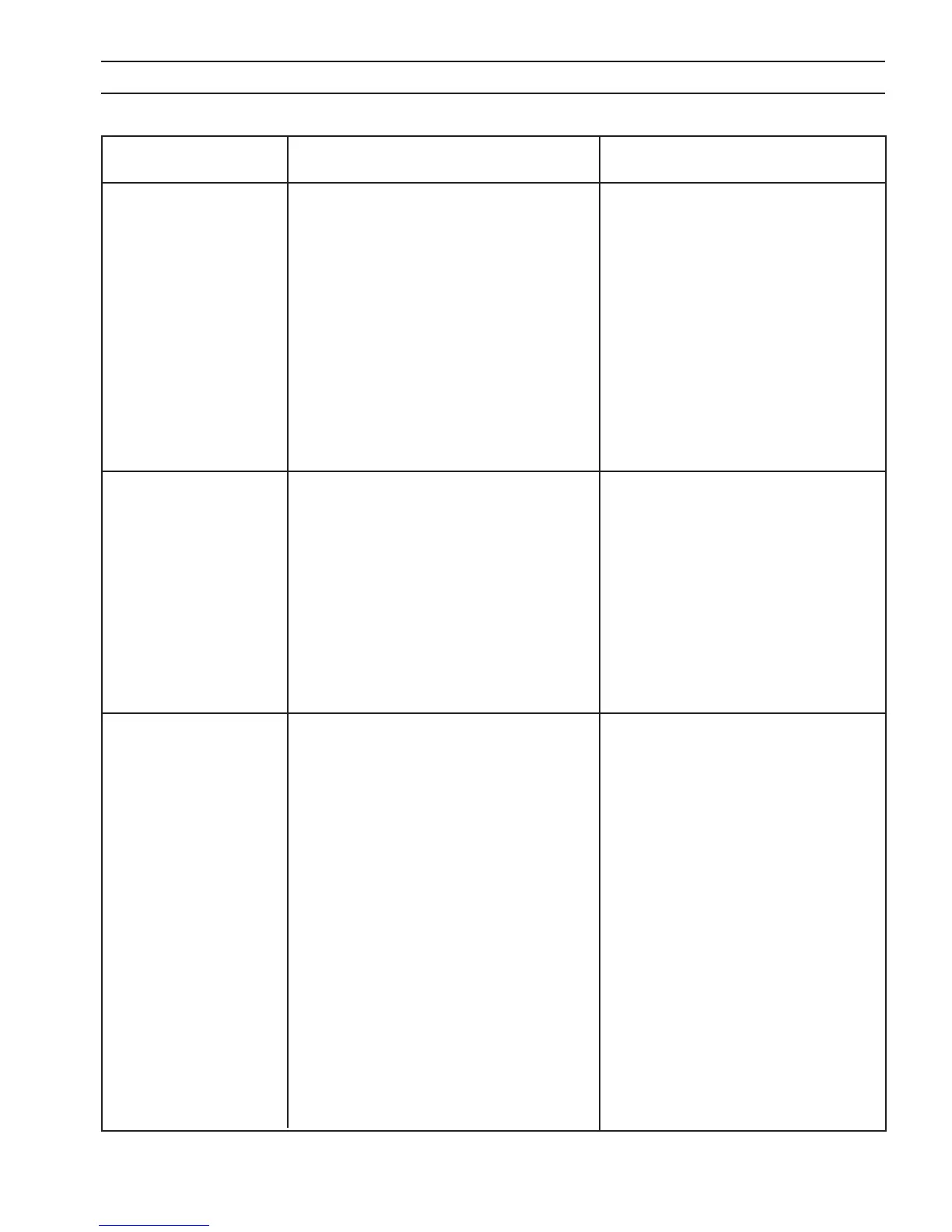

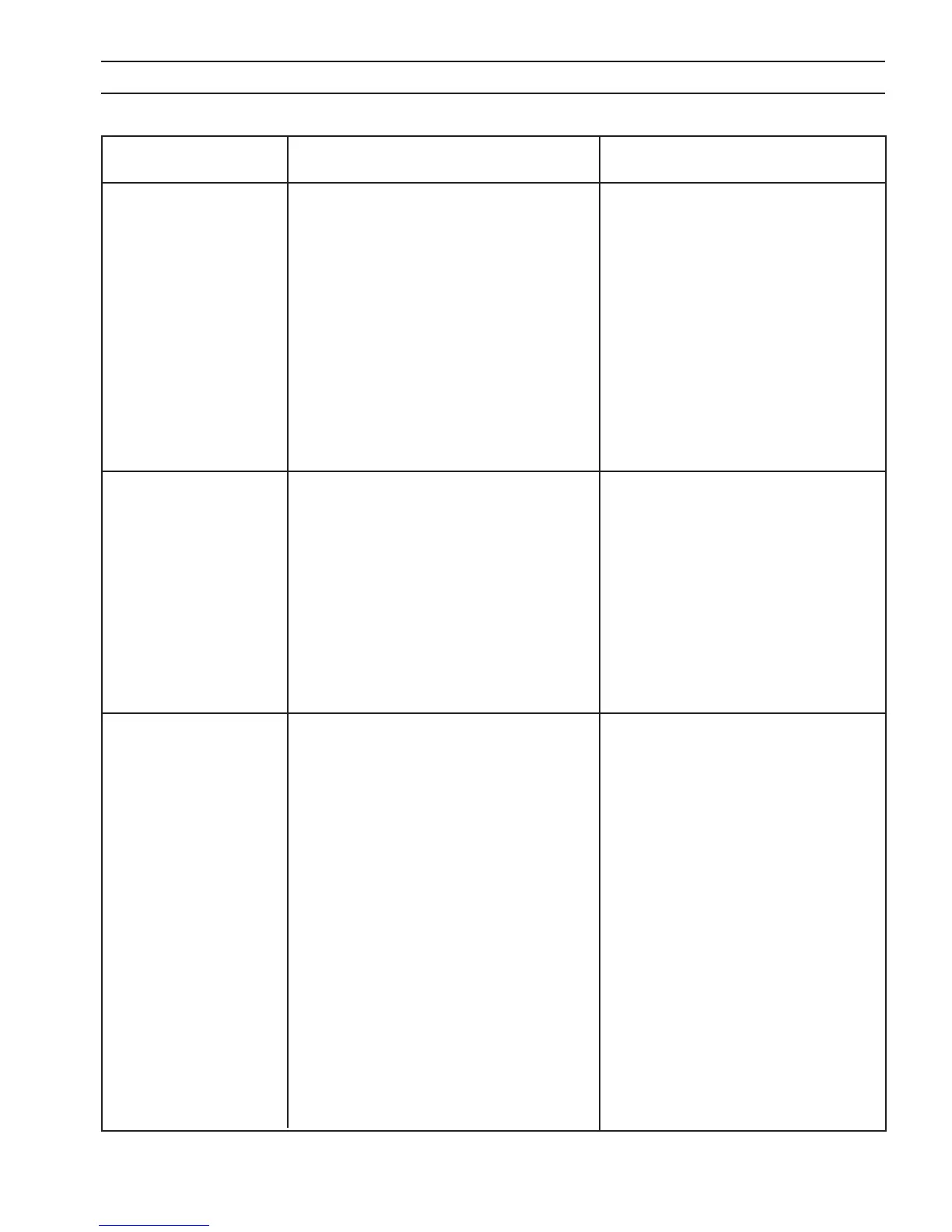

SECTION 6 TROUBLESHOOTING

Problem Possible Cause Corrective Action

Torch Fails to Fire

Positive Cut Angle

Negative Cut Angle

1. Start gas too high.

2. Coolant ow switch not satised.

3. Torch parts worn out.

4. Start signal not present

5. Pressure switches for gas not satised.

6. Power supply problem.

1. Arc voltage too high.

2. Cutting speed too fast.

3. Cutting current too high.

1. Arc voltage too low.

2. Cutting speed too slow.

3. Cutting current too low

1. Lower start gas ow.

2. a). Pump pressure too low,

should be 90 - 100 psig.

b). Faulty coolant ow switch.

c). Obstruction in torch limiting

coolant ow.

3. Service torch as outlined in the torch

manual.

4. Trouble shoot signal path.

5. Check for proper pressure and ow.

6. Run through all setup procedures.

1. Lower arc voltage in small (5 Volt)

increments.

2. If cutting speed is too fast,

decrease speed.

3. a). Wrong nozzle being used.

b). Lower current into correct

operating range.

1. Raise the arc voltage in small incre-

ments (5 Volts).

2. Simply increase speed.

3. Change to a higher current nozzle.

Loading...

Loading...