8

3.1 GENERAL

Before any maintenance is attempted on this

torch, make sure the power switch on the console

is in the "OFF" position and the primary input is

deenergized.

3.2 INSPECTION AND CLEANING OF

CONSUMABLES

A. Disassemble the front end of the PT-27 as

follows:

1. Position torch head in a downward direction

(refer to Figure 2-1) and remove the shield.

The nozzle, swirl baffle, and electrode will

drop from the head and remain in the shield.

Remove these components and inspect for

wear. The nozzle and electrode will generally

wear at the same rate. For best performance,

replace together.

2. Nozzle: Replace if the orifice is clogged, nicked,

or out-of-round.

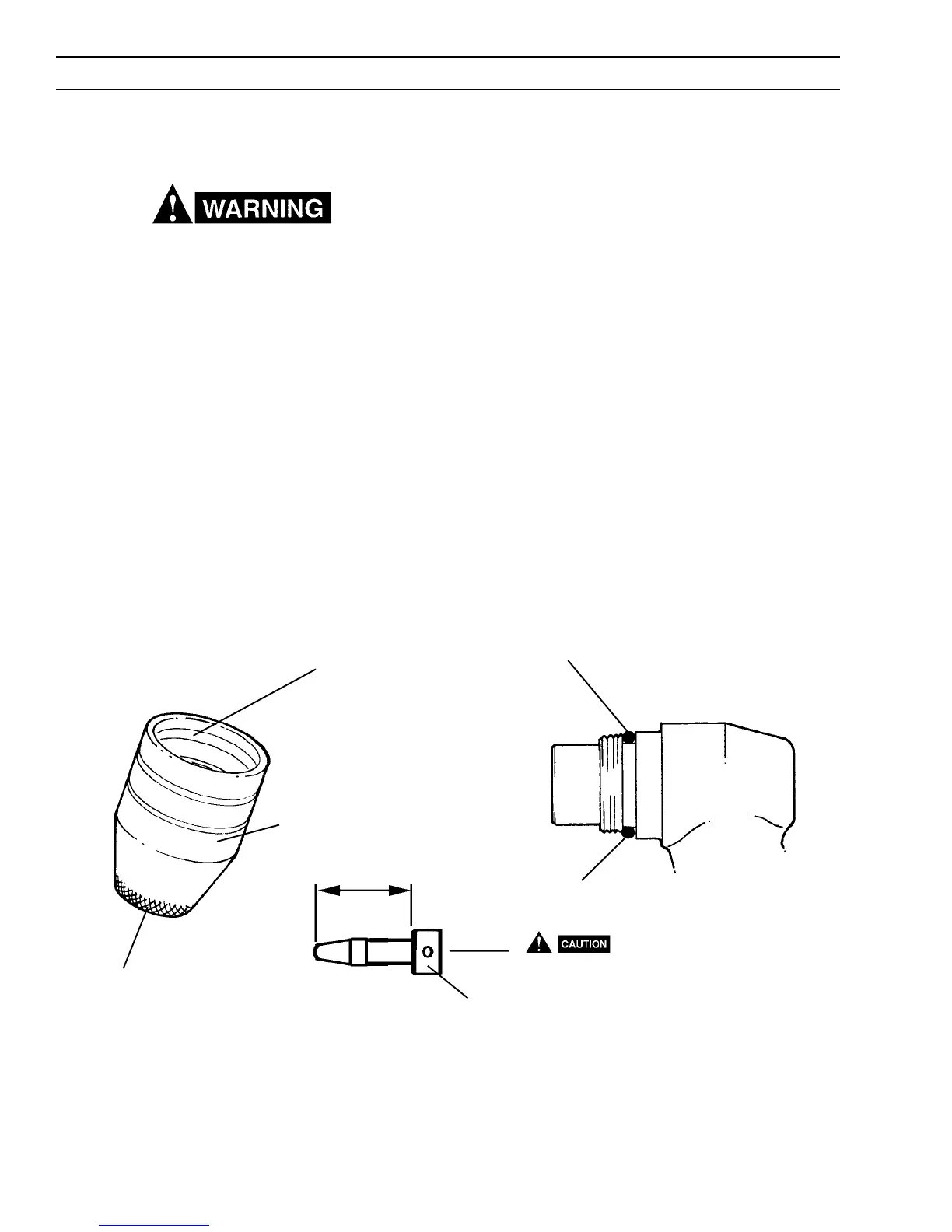

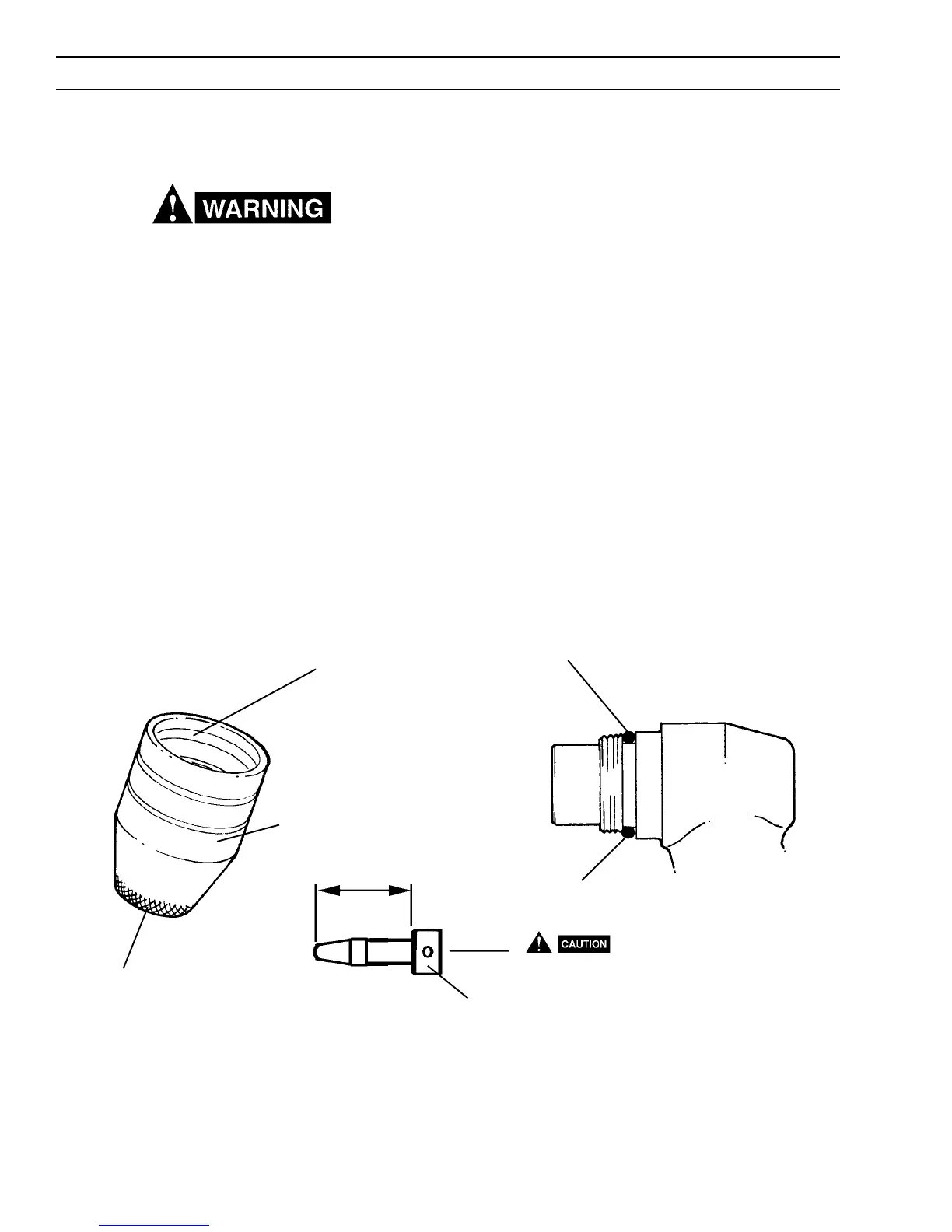

3. Electrode: See Figure 3-1 for electrode main-

tenance.

4. Shield: The face of the shield will gradually

erode from the heat and molten metal spray.

Replace the shield if more than 1/8 inch (3.2

mm) has eroded from the face. Refer to Figure

3-1.

5. Swirl Baffle: This is a ceramic part and may

crack or chip if dropped. Always replace if

cracks or chips are present.

6. O-ring: Lubricate as per Figure 3-1. Replace

if cut or worn. Air leaking past this seal will

reduce cutting performance.

B. To replace the above front end components,

refer to Figure 2-1.

HEAT SHIELD

Figure 3-1. O-ring, Electrode, and Shield Maintenance

LUBRICANT (P/N 17672) CAN BE

APPLIED TO O-RING OR HEAT SHIELD.

THE HEAT SHIELD FACE WILL

GRADUALLY ERODE WITH USE.

SEE PARAGRAPH 3.2.A.4.

19/32"

(15.1 mm)

REPLACE ELECTRODE BEFORE

LENGTH BECOMES SHORTER THAN 19/

32 INCH -

(15.1 mm).

O-RING

ELECTRODE

SECTION 3 MAINTENANCE

Loading...

Loading...