MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

17

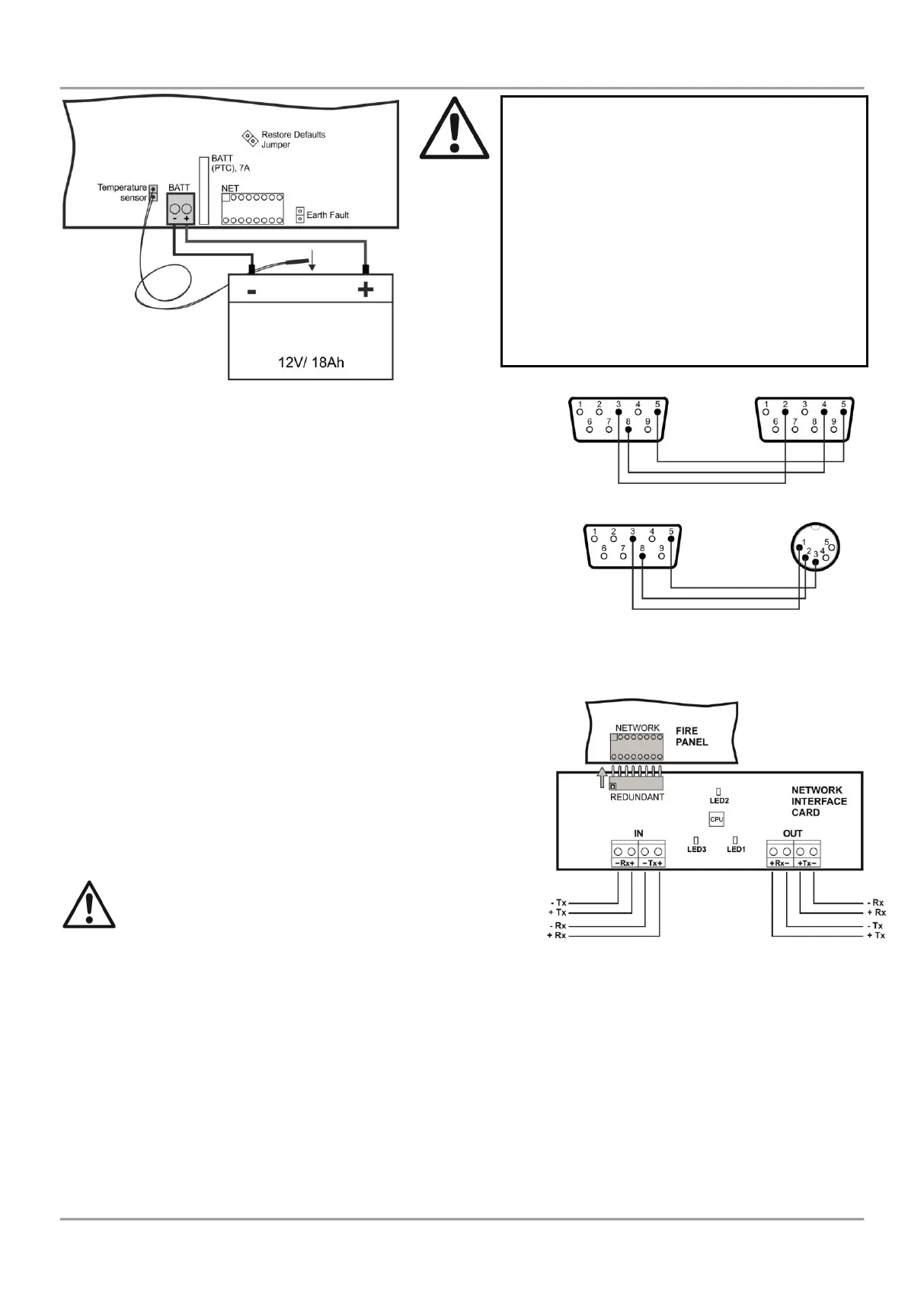

2.6. Connecting a Heat Printer

The addressable fire alarm panel MAGPRO16 is equipped with RS232

interface connector, situated in the middle of the main PCB, for

connecting a heat printer. The heat printer allows the technician to print

the log file for the alarm and fault events, warnings and changes during

programming. The capacity of log file is 10 240 events, which are

saved with date and time of occurring – see also item 7.1.4.

The addressable fire alarm panel MAGPRO16 supports Canon 9 type

external printers, models Kafka and Datecs. For connecting the

MAGPRO16 panel to the heat printer you have to prepare a special

cable for the purpose – connect two male DB9-DB9 (Datecs printer) or

DB9-DIN5 (Kafka printer) type connectors as shown on Figure 18.

Before printing (access levels 2 and 3) make sure that the heat printer

is connected to the ‘PRINTER’ interface connector on the main PCB

and the printer is powered on.

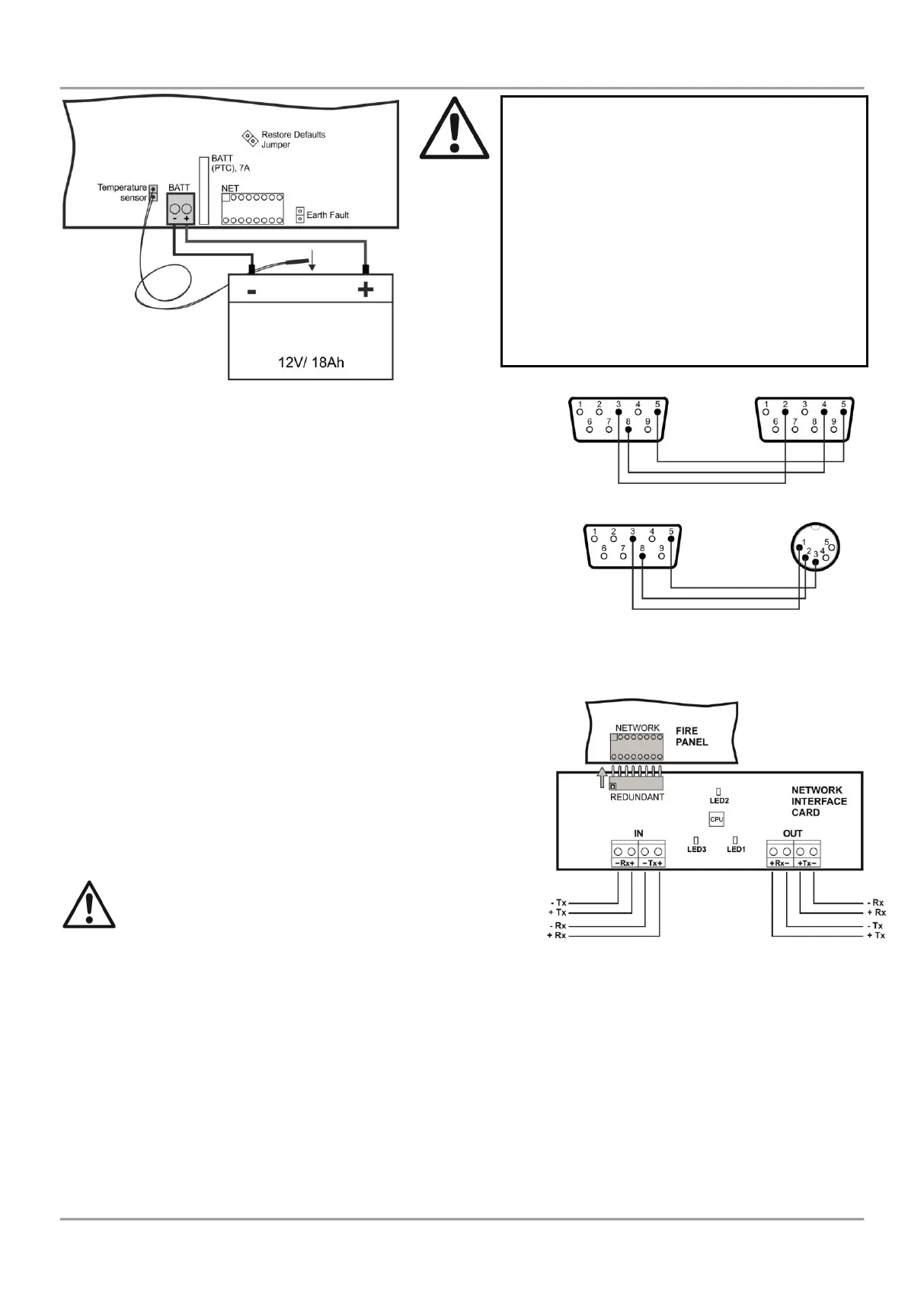

2.7. Connecting a Network Interface Card (MAGPRO-NIC)

The addressable fire alarm panel MAGPRO16 is designed with option

for connection in a Ethernet network with other MAGPRO16 or

MAGPRO96 addressable panels (up to 32). The network interface

card is mounted under the main PCB and is connected to ‘NET’

connector – Figure 19. The card should be fixed with screws to the

metal bottom. The maximum cable length between two network

interface cards is 1000m.

Attention: NEVER add or remove the network interface

card to the fire panel configuration WHEN THE MAIN

AND BACKUP POWER SUPPLIES ARE ON!

2.8. Connecting an AJAX LAN Communication Module

The addressable fire alarm panel MAGPRO16 is designed for monitoring via serial interface connection using

specialized AJAX communication module. The monitoring could be realized over LAN network, according the type of

the used module. The communication module is mounted on the place under the second loop controller and it is fixed

with suitable screws to the metal bottom. The connection is realized with interface flat cable between the ‘AJAX’

connector on the main PCB and the interface connector on the communication module itself.

Attention: NEVER add or remove the communication module to the fire panel configuration WHEN THE MAIN

AND BACKUP POWER SUPPLIES ARE ON!

Attention: The connection between the

accumulator battery and the main power

source has some special features.

It is strongly recommended to use only

battery with electrical characteristics and

dimensions pointed from the manufacturer.

Before connecting to the power source

check the polarity of the battery. Connect the

battery after the mains supply is turned on.

If the battery is new it will take a few hours

before its complete charging!

Figure 17. Connecting

the accumulator battery

Attention: The connection between the

accumulator battery and the main power

source has some special features.

It is strongly recommended to use only battery

with electrical characteristics and dimensions

pointed from the manufacturer.

Before connecting to the power source check

the polarity of the battery. Connect the battery

after the mains supply is turned on.

If the battery is new it will take a few hours

before its complete charging!

To measure the current temperature of the

battery, place the temperature sensor behind

or under the battery.

Loading...

Loading...