EVCO S.p.A. EVJ800 | Installer manual ver. 1.0 | Code 144J800E104

page 7 of 48

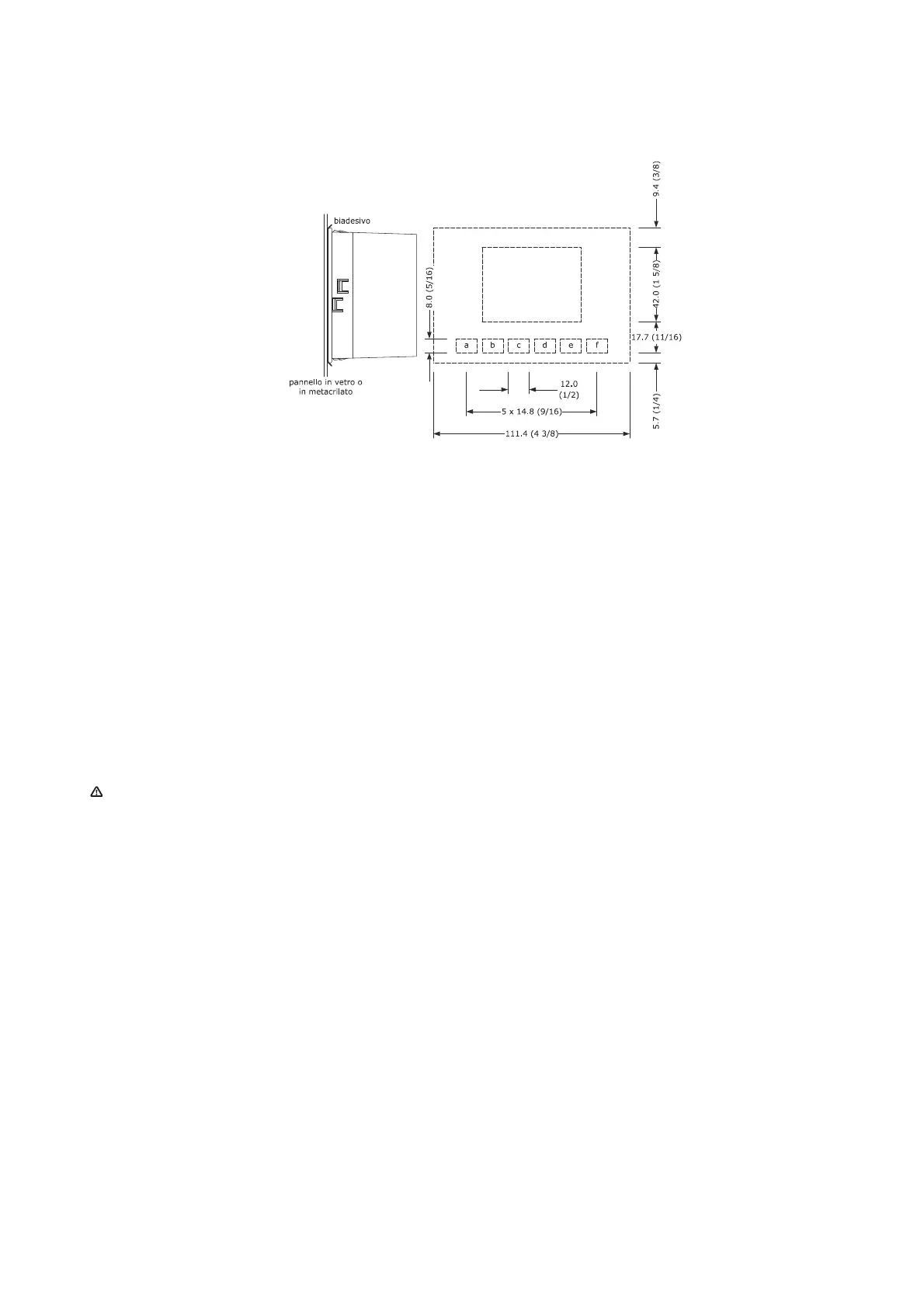

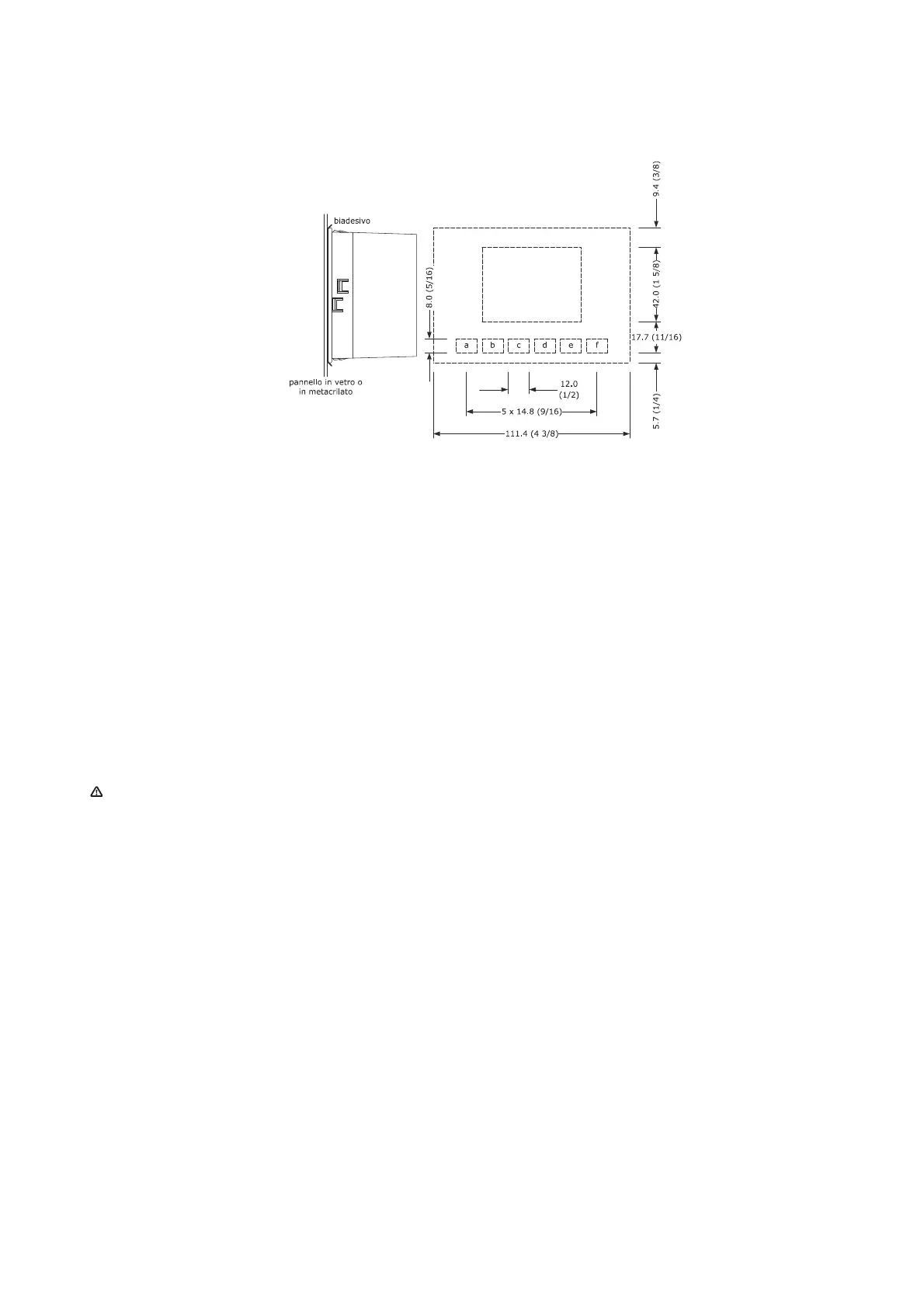

Panel, from behind

N.B.

- the thickness of a glass panel must be between 2.0 and 4.0 mm (1/16 and 1/8 in), while that for a

methacrylate panel must be between 2.0 and 3.0 mm (1/16 and 1/8 in).

- the panel and the material used to carry out screen printing must not contain conductive substances.

- keep the device and the panel at a temperature between 15 and 38°C (59 and 100°F) for about an hour

before carrying out the installation.

- before installation, carefully clean the panel surface that will be in contact with the double-sided

adhesive tape, making sure that the product used for cleaning is suitable for the panel material (we

recommend using isopropyl alcohol, in the case of surfaces greased with a hydrocarbon solvent).

Continue cleaning with a cloth until it is clean and dry after use.

- during installation, apply a uniform and constant pressure for about 30 secs on the panel surface in

contact with the double-sided adhesive tape. Then leave the device and the panel in a horizontal position

for about 48 hours at a temperature between 15 and 38°C (59 and 100°F).

Installation precautions

- ensure that the working conditions for the device (operating temperature, humidity, etc.) are within the

set limits. See section 10 TECHNICAL SPECIFICATIONS.

- do not install the device close to heat sources (heaters, hot air ducts, etc.), equipment with a strong

magnetic field (large diffusers, etc.), in places subject to direct sunlight, rain, damp, excessive dust,

mechanical vibrations or shocks.

- any metal items close to the control module must be at a sufficient distance so as not to compromise the

safety distance; any cabling must be placed at least 2 cm away.

- in compliance with safety regulations, the device must be installed properly to ensure adequate

protection from contact with electrical parts. All protective parts must be fixed in such a way as to need

the aid of a tool to remove them.

Loading...

Loading...