45

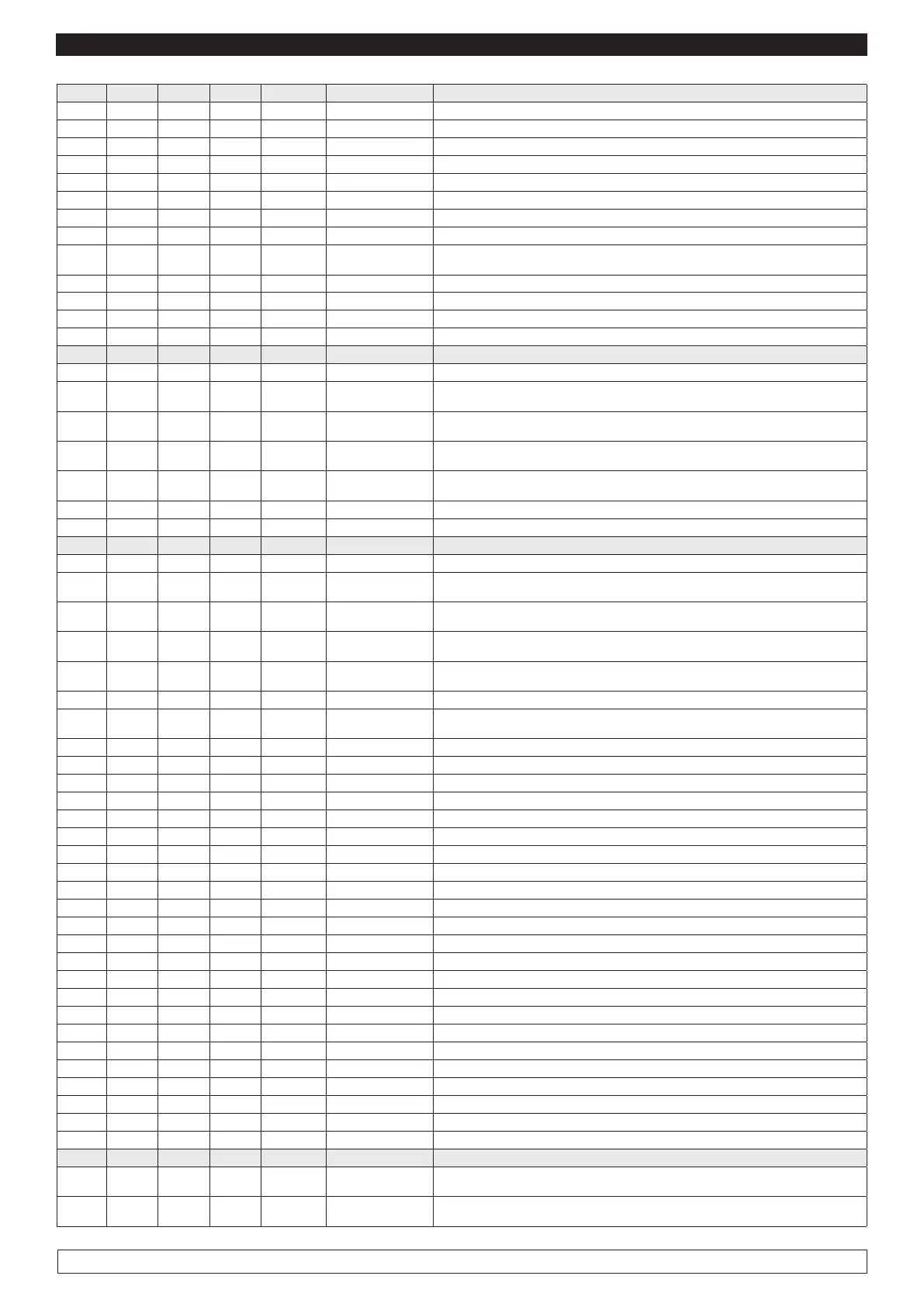

RETARDER PROOFER CABINETS/TABLES AND DOUGH-RETARDER PARAMETERS

Par. Min. Mas. Unit Dough

Retarder-Proofer

Analog inputs

CA1 ¬25 25 °C 0 0

Offset cell probe

CA2 ¬25 25 °C 0 0

Offset evaporator probe

CA3 ¬25 25 °C 0 0

offset condenser probe

CA4 ¬25 25 %r.H. 0 0

offset humidity probe

P0 0 1 ¬¬¬¬ 1 1

Type of probe 0 = PTC 1 = NTC

P2 0 1 ¬¬¬¬ 0 0

Temperature unit of measure 0 = °C 1 = °F

P3 0 1 ¬¬¬¬ 1 1

Enabling of evaporator probe 0 = disabled 1 = enabled

P4 0 1 ¬¬¬¬ 0 0

Enabling of condenser probe 0 = disabled 1 = enabled

P5 0 60 Min 60 60

duration of a power failure while a higher cycle which is signaled by the power failure

alarm

P6 0 2 ¬¬¬¬ 1 1

Reserved

P7 0 P8 %r.H. 0 0

Lower limit of humidity transducer calibration range (equal to 4mA)

P8 P7 100 %r.H. 100 100

Higher limit of humidity transducer calibration range (equal to 20mA)

P9 0 250 ds 5 5

Delayed visualisation of the temperature variation detected by probes

Par. Min. Mas. Unit Dough

Retarder-Proofer

Cold Regulator

rC0 1 15 °C 2 2

Variation of the rC3, rC4, rC5 parameters

rC1 ¬99 rC2 °C ¬-10 -10

Minimum setpoint that can be set for the block phases, the preservation and the manual

cooling operations

rC2 rC2 99 °C 20 20

Maximum setpoint that can be set for the block phases, the preservation and the manual

cooling operations

rC3 0 10 °C 1 1

Values of cold neutral zone for the block phase, the preservation and the manual cooling

operations

rC4 0 10 °C 1 1

Values of cold neutral zone for the proong , the leavening and the manual heating

operations

rC5 0 10 °C 1 1

Values of cold neutral zone for the delayed baking phase

rC6 ¬99 99 °C -5 -5

precooling setpoint

Par. Min. Mas. Unit Dough

Retarder-Proofer

Hot Regulator

rH0 1 15 °C 2 2

Variations of the rH3, rH4, rH5 parameters

rH1 ¬99 rH2 °C 0 0

Minimum setpoint that can be set for the proong phase, the leavening , the delayed

baking and the manual heating operations

rH2 rH2 99 °C 40 40

Maximum setpoint that can be set for the proong phase, the leavening, the delayed

baking and the manual heating operations

rH3 0 10 °C 1 1

Value of warm neutral zone for the block phases, the preservation and the manual hea-

ting operation

rH4 0 10 °C 1 1

Value of warm neutral zone for the proong phases, the leavening and the manual hea-

ting operation

rH5 0 10 °C 1 1

Value of warm neutral zone for the delayed baking phase

rH6 1 600 sec 60 60

Cycle time for the starting of the heating resistors in case warmth is required (see also

rH7)

rH7 1 600 sec 60 60

Switch-on time for the heating resistors within the limit of the cycle time stated at rH6

rr0 1 10 ¬¬¬¬ 1 1

Number of adjustment pitches during the proong phase

rr1 1 rr2 % 100 100

Percentage increase 1° proong step (compared to 100% total)

rr2 rr1 rr3 % 1 1

Percentage increase 2° proong step (compared to 100% total)

rr3 rr2 rr4 % 1 1

Percentage increase 3° proong step (compared to 100% total)

rr4 rr3 100 % 1 1

Percentage increase 4° proong step (compared to 100%)

rr5 rr4 rr6 % ¬¬¬¬- -

Percentage increase 5° proong step (compared to 100%)

rr6 rr5 rr7 % ¬¬¬¬- -

Percentage increase 6° proong step (compared to 100%)

rr7 rr6 rr8 % ¬¬¬¬- -

Percentage increase 7° proong step (compared to 100%)

rr8 rr7 rr9 % ¬¬¬¬- -

Percentage increase 8° proong step (compared to 100%)

rr9 rr8 rr10 % ¬¬¬¬- -

Percentage increase 9° proong step (compared to 100%)

rr10 rr9 100 % ¬¬¬¬- -

Percentage increase 10° proong step (compared to 100%)

rL0 1 10 ¬¬¬¬ 1 1

Number of resistors adjustment pitches during the leavening phase

rL1 1 rL2 % 100 100

Percentage increase 1° leavening step (compared to 100%)

rL2 rL1 rL3 % 1 1

Percentage increase 2° leavening step (compared to 100%)

rL3 rL2 rL4 % 1 1

Percentage increase 3° leavening step (compared to 100%)

rL4 rL3 100 % 1 1

Percentage increase 4° leavening step (compared to 100%)

rL5 rL4 rL6 % ¬¬¬¬- -

Percentage increase 5° leavening step (compared to 100%)

rL6 rL5 rL7 % ¬¬¬¬- -

Percentage increase 6° leavening step (compared to 100%)

rL7 rL6 rL8 % ¬¬¬¬- -

Percentage increase 7° leavening step (compared to 100%)

rL8 rL7 rL9 % ¬¬¬¬- -

Percentage increase 8° leavening step (compared to 100%)

rL9 rL8 rL10 % ¬¬¬¬- -

Percentage increase 9° leavening step (compared to 100%)

rL10 rL9 100 % ¬¬¬¬- -

Percentage increase 10° leavening step (compared to 100%)

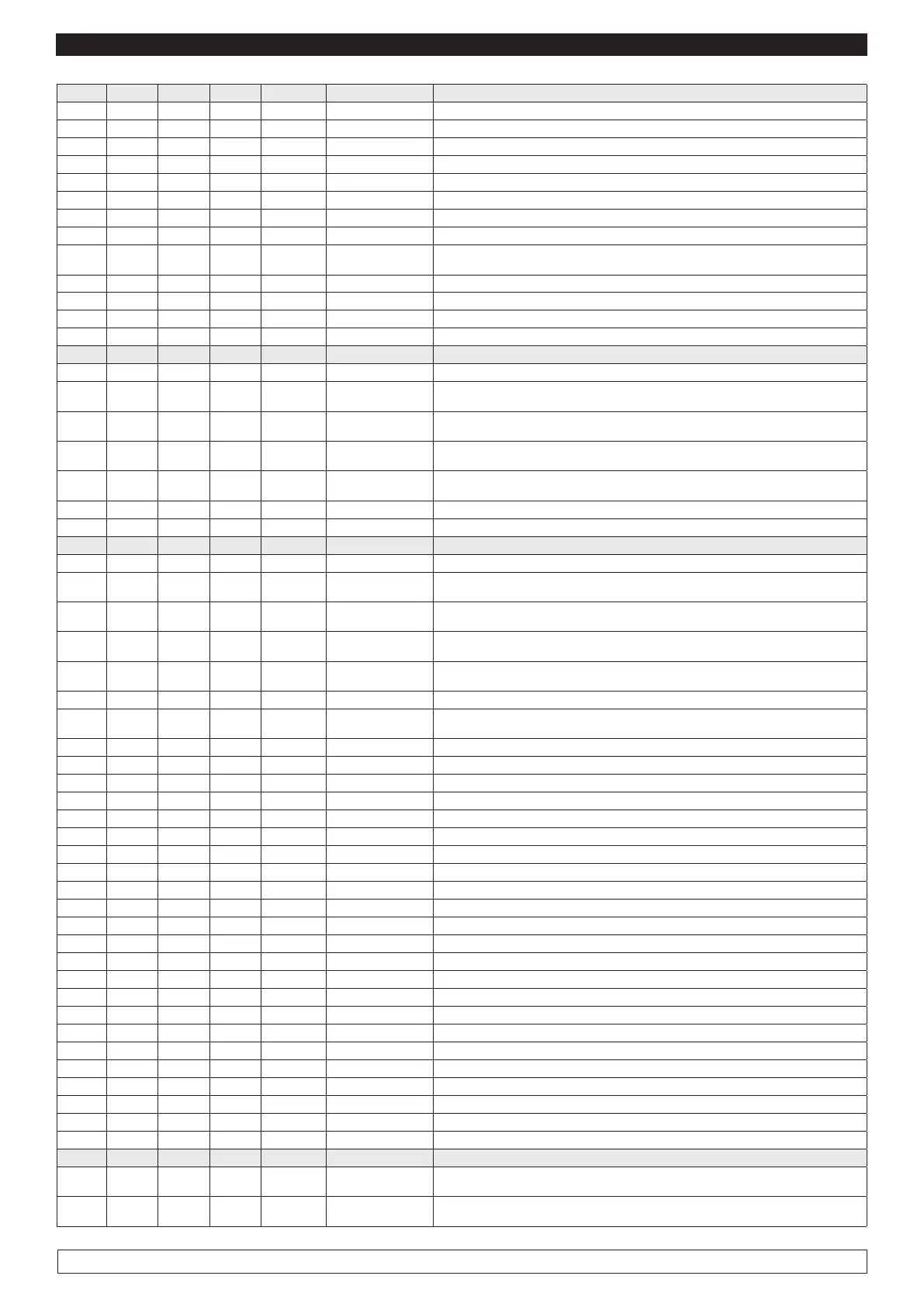

Par. Min. Mas. Unit Dough

Retarder-Proofer

Humidity Regulator

rU0 0 1 ¬¬¬¬ 1 0

Humidity management mode : 0 = with humidity probe 1 = time cycles based on the set

percentange

rU1 ¬99 99 °C 7 7

minima temperatura in cella al di sotto della quale il controllo umidicazione/deumidica-

zione viene inibito

Loading...

Loading...