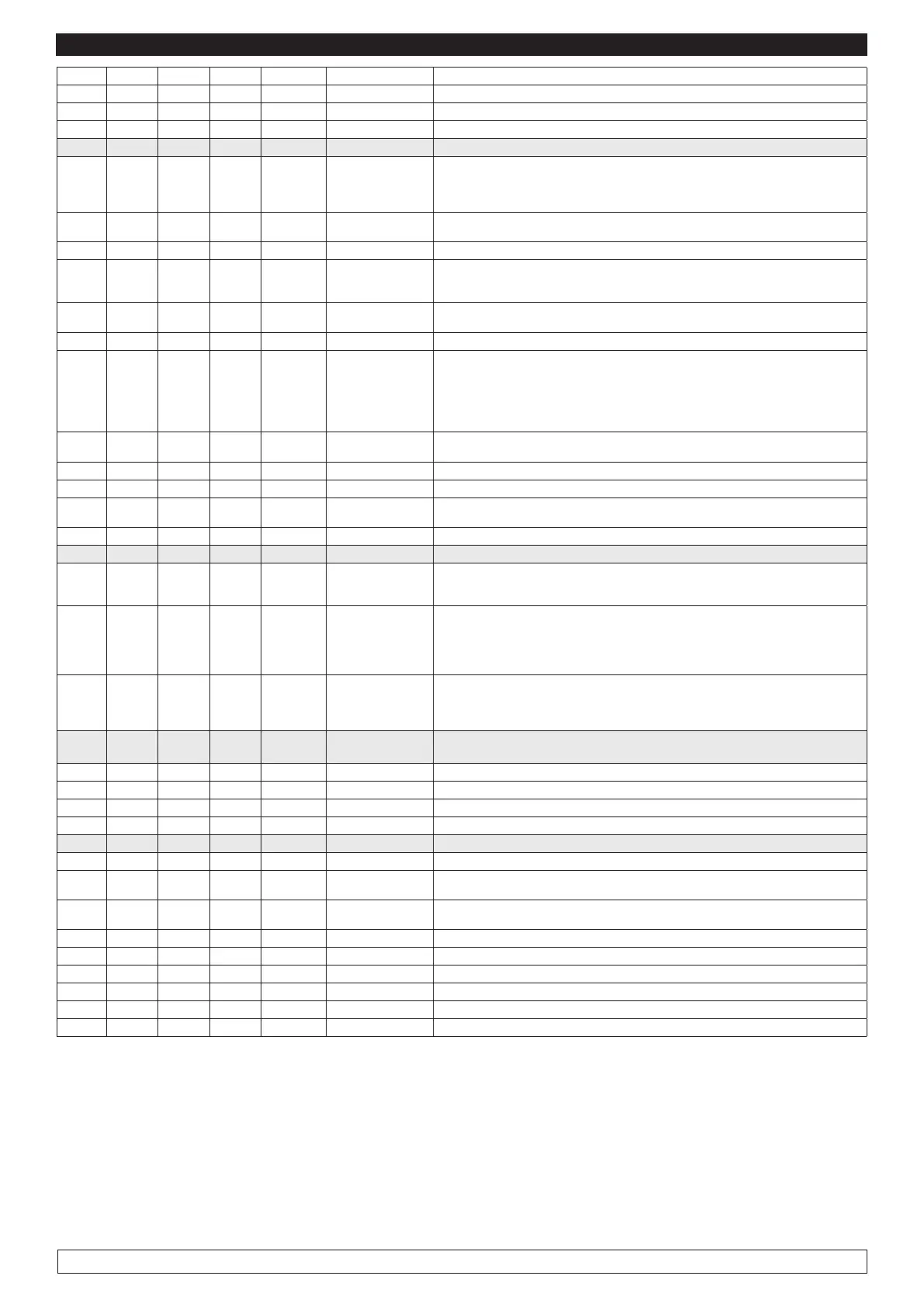

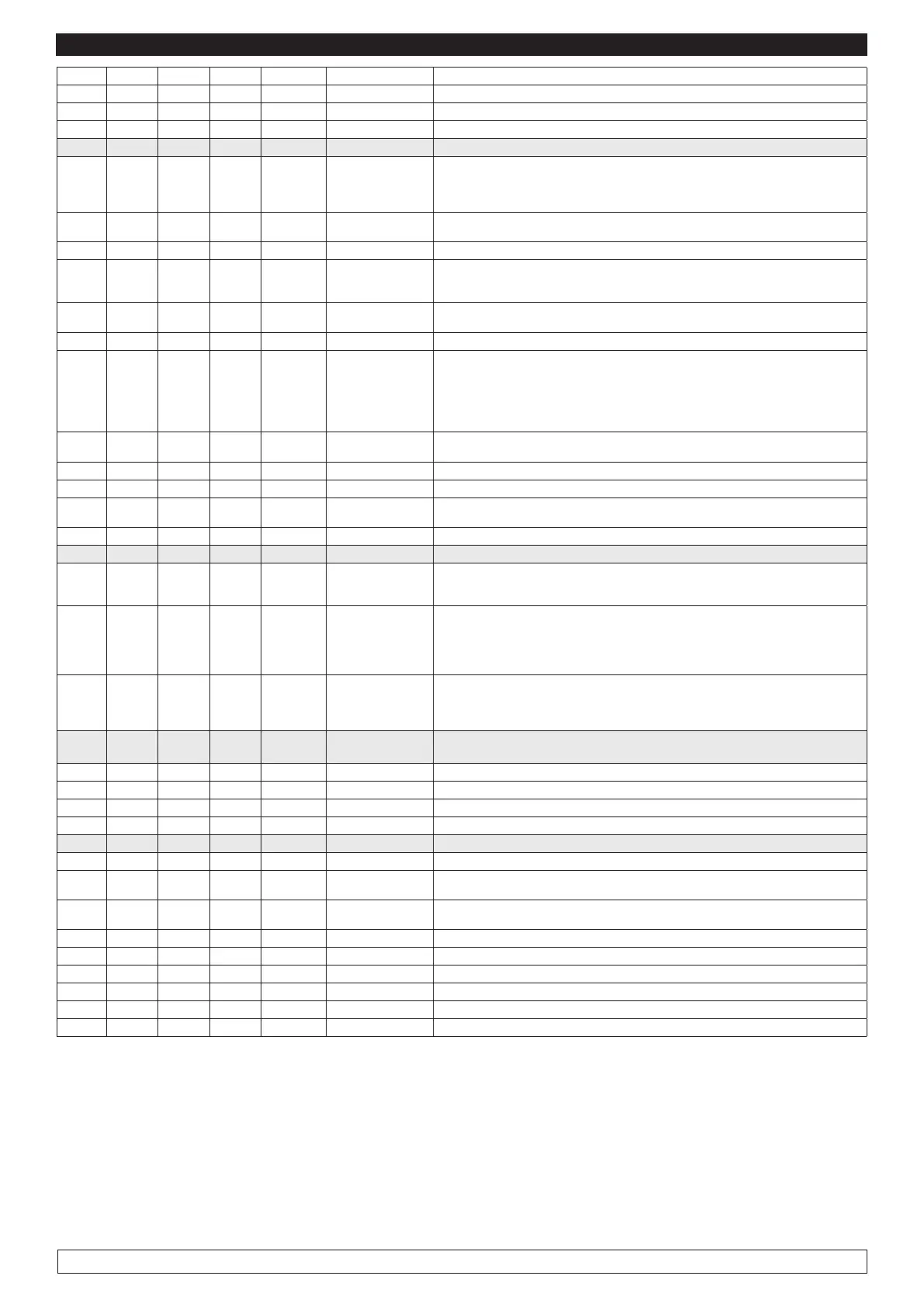

47

F22 1 10 s 10 10

Time cue at the evaporator fan switching-on

F23 0 100 % 0 0

Calibration value of the evaporator fan minimum speed

F24 0 100 % 100 100

Calibration value of the evaporator fan maximum speed

F25 -50 99 °C 99 99

Temperature for evaporator fan stop

Par. Min. Mas. Unit Dough

Retarder-Proofer

Digital inputs

i0 0 2 ¬¬¬¬ 1 1

Effect caused by the door opening, i.e. by the micro door input activation 0 = no effect

1 = the compressor, the evaporator fan and the heating resistors will be switched off,

the cell light will be switched on 2 = the evaporator fan and the heating resistors will be

switched off . The cell light will be switched on

i1 0 1 ¬¬¬¬ 1 1

Type of contact of the micro door input 0 = normally-open (active input with closed con-

tact) 1 = normally-closed (active input with open contact)

i2 ¬1 120 min -1 -1

Delayed alarm warning when the door is open (code “id”) -1 = the alarm is not reported

i3 0 1 ¬¬¬¬ 1 1

Effect caused by the activation of the high pressure input 0 = no effect 1 = the compres-

sor and the evaporator fan will be switched off and the condenser fan will be switched

on

i4 0 1 ¬¬¬¬ 0 0

Type of contact of the high pressure input 0 = normally open (active input with closed

contact) 1 = normally closed (active input with open contact)

i5 ¬1 240 s 5 5

High pressure delayed alarm warning (code “HP”) 1 = the alarm is not reported

i6 0 2 ¬¬¬¬ 1 1

Effect caused by the activation of the low pressure input 0 = no effect 1 = alarm. The

compressor and the evaporator fan will be switched off , 2 = pumpdown management

and alarm. During the compressor switching off the intervention of the digital input will

switch off the compressor output because of the pumpdown end-of-phase . During the

activation of the cooling system, the intervention of the digital input will switch off the

compressor and the evaporator fan.

i7 0 1 ¬¬¬¬ 0 0

Type of low pressure input contact 0 = normally open (open input with closed contact) 1

= normally closed (active input with open contact)

i8 ¬1 240 s 10 10

Low pressure delayed alarm warning (code “LP”) 1 = the alarm is not reported

i9 0 240 s 40 40

Low pressure limiter reset time when the compressor is being switched on (if i6 = 2 only)

i10 0 1 ¬¬¬¬ 0 0

Type of contact of the thermal protector input 0 = normally open (active input with closed

contact) 1 = normally closed (active input with open contact)

i11 ¬1 240 s 5 5

Thermal protector delayed alarm warning (code “CtH”) 1 = the alarm is not reported

Par. Min. Mas. Unit Dough

Retarder-Proofer

Digital outputsi

u1 0 1 ¬¬¬¬ 1 1

Utility managed by the K8 output 0 = pump down valve (in this case the u2 parameter

will be signicant) 1 = evaporator fan (in this case the output will repeat on ON/OFF

mode the PWM output status dedicated to the evaporator fan)

u2 0 240 s 10 10

If i6 = 0 or 1: compressor delayed deactivation from the pump down valve switching off

(pump down in shutdown, for u1 = 0 only) If i6 = 2: Maximum duration of pumpdown in

compressor shutdown without the activation of the low pressure input so as to cause

the compressor switching off and the pumpdown alarm warning 0 = the alarm is not

reported

u3 0 1 ¬¬¬¬ 1 1

Utility managed by the K4 output0 = dehumidier /extraction fan (in this case the rU5

and rU6 parameters will be signicant) 1 = condenser fan (in this case the F16 and F17

parameters will be signicant) PLEASE NOTE: with u3 = 1 the dehumidier activity is

automatically managed by the activation of the cooling system

Par. Min. Mas. Unit Dough

Retarder-Proofer

Serial communication (serial door RS485 with MODBUS communication

protocol)

L1 1 240 min 5 5

Sample time of internal data

LA 1 247 ¬¬¬¬ 247 247

Device address

Lb 0 3 ¬¬¬¬ 2 2

baud rate 0 = 2.400 baud 1 = 4.800 baud 2 = 9.600 baud 3 = 19.200 baud

LP 0 2 ¬¬¬¬ 2 2

Even parity 0 = none (no parity) 1 = odd (odd) 2 = even (parity)

Par. Min. Mas. Unit Dough

Retarder-Proofer

Others

E8 0 2 ¬¬¬¬ 0 0

Key lock 0 = disabled 1= manual 2 = automatic after 1 minute of inactivity during a cycle

E9 0 1 ¬¬¬¬ 0 0

Visualisation of splash screen EVCO on restoration of power supply 0 = black screen 1

= splash EVCO

E10 0 1 ¬¬¬¬ 0 0

Display positioning 0 = the device is placed above unit 1 = the device is placed below

unit

E11 0 120 s 10 10

Duration of the buzzer signal during the precooling and the end-of-cycle phase

E12 0 1 ¬¬¬¬ 0 0

reserved

E13 0 1 0 0

Unlock humidier management with serial control

E14 0 1 1 1

Enable the block phase in case of automatic programs

E15 0 1 0 0

Reserved

E16 0 0 0 0

Reserved

Loading...

Loading...