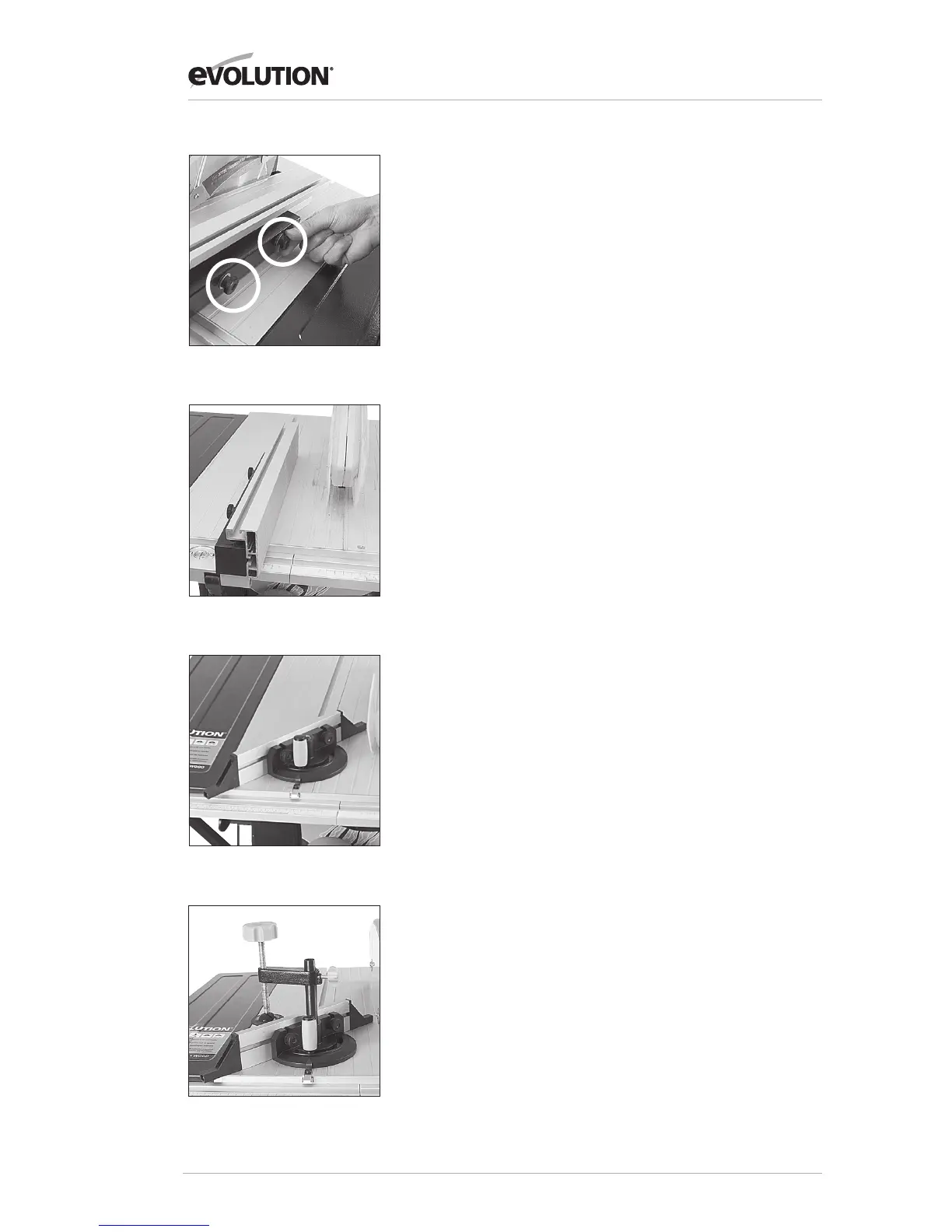

Forwards and backwards adjustment of the rip fence is possible.

Loosen the two finger nuts and slide the aluminium extrusion

to the desired position. Tighten the finger nuts securely.

Note: We recommend that normally the rip fence be adjusted

so that the rear of the guide is level with the rear of the blade

where it emerges from the table. See Fig 21.

Note: If the rip fence is used on the LH side of the blade

the aluminium extrusion will have to be repositioned to

the RH side of the steel box-section carrier.

Undo the two wing nuts and remove the aluminium extrusion

with its bolts in place. Reposition the extrusion on the RH side

of the steel carrier and re-attach the wing nuts. See Fig 22.

Adjust as above.

Remember to return to the original configuration when the rip

fence is in the normal (RH) operating position.

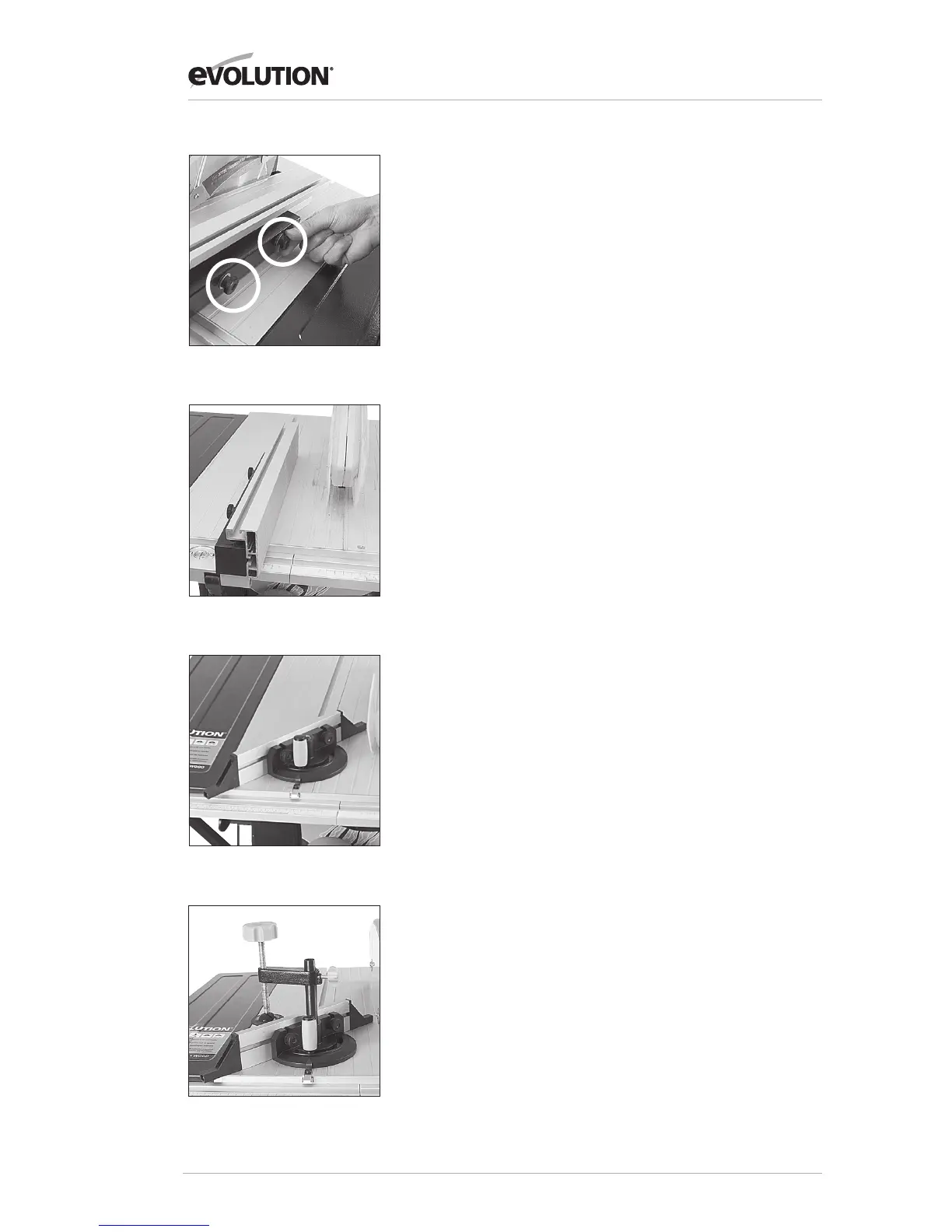

5. Mitre Gauge

The mitre gauge can be used on either side of the table and

runs in two inverted T slots in the table top.

Turn the vertical handle counter-clockwise to unlock

the mitre gauge, and adjust to the required angle.

Turn the handle clockwise to lock the mitre gauge

at the chosen angle. See Fig 23.

Note: The extruded aluminium face plate of the mitre

gauge should be adjusted so that it is close to, but does not

foul the blade guard. Adjust by loosening the two wing nuts

and sliding the faceplate to the required position. Securely

tighten the wing nuts.

6. ANTIBOUNCE DEVICE

If required, when cutting thin sheet or thin walled box-section

material (maximum 3mm thickness applies when Steel cutting),

the anti-bounce device can be employed. See Fig 24. Adjust

using the adjustable handle and knob for best position.

Note: Adjust the anti-bounce device so that the head does

not quite touch the material to be cut. You can achieve this by

gently clamping the material to be cut with the anti-bounce

device, and then backing off the head by 1/4 to1/2 a turn.

Fig 21

Fig 22

Fig 23

Fig 24

Loading...

Loading...