Operation

Seethedecalonthesideofthedeckliftplatefor

cutheights.

6.Pushthedeckliftpedal,releasethetransportlock

andallowthedecktolowertothecuttingheight.

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

position,whentheheightofcuthaschanged.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthemounting

hardware.

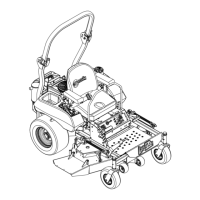

6.Placetherollersinoneofthepositionsshown

(Figure18).Rollerswillmaintain3/4inch(19

mm)clearancetothegroundtominimizegouging

androllerwearordamage.

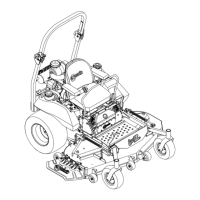

Figure18

Forcuttingheightsabove3.5inches(90mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

ForMaximumDeckFlotation,placetherollers

oneholepositionlower.Rollersshouldmaintain

1/4inch(6.4mm)clearancetotheground.Do

Notadjusttherollerstosupportthedeck.

7.Reinstallthemountinghardware.

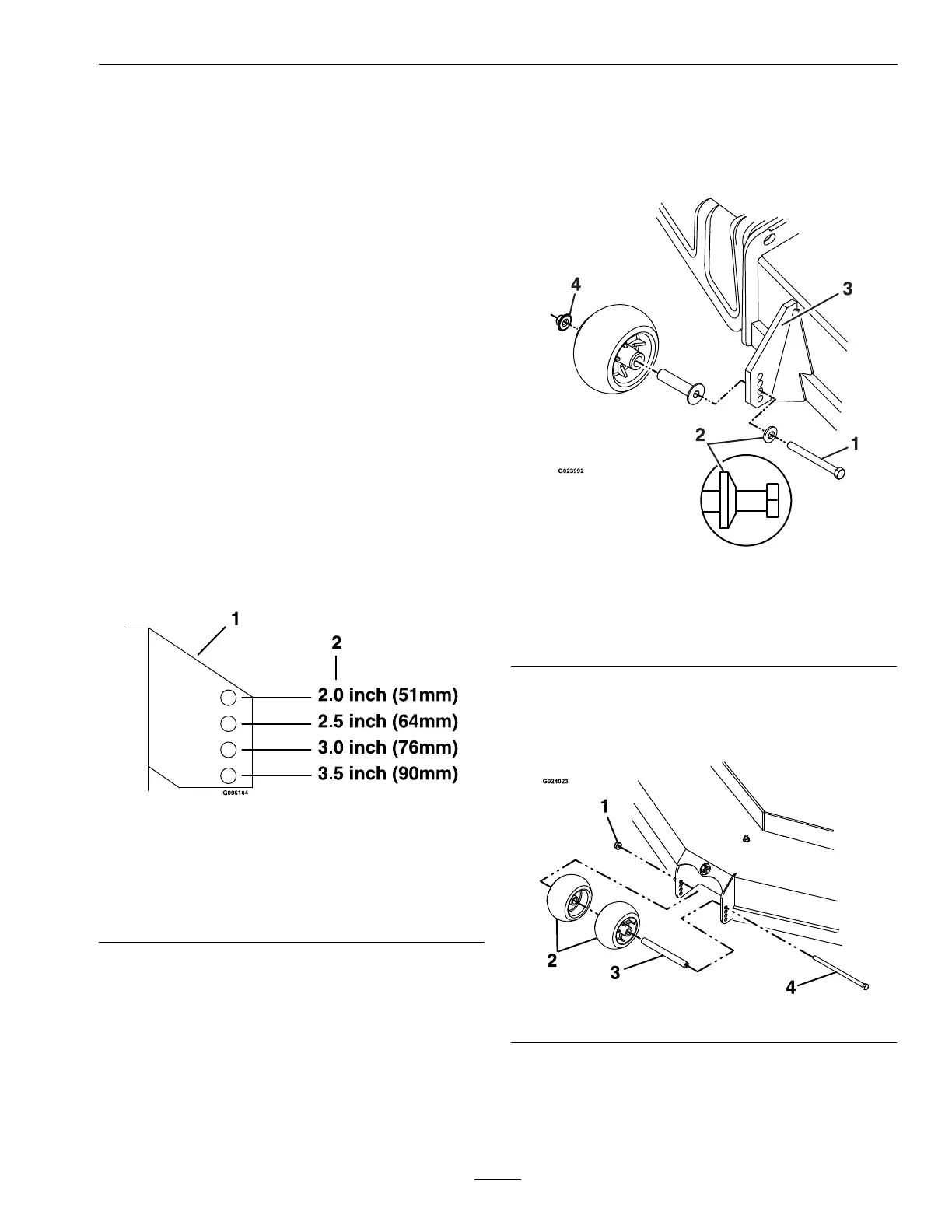

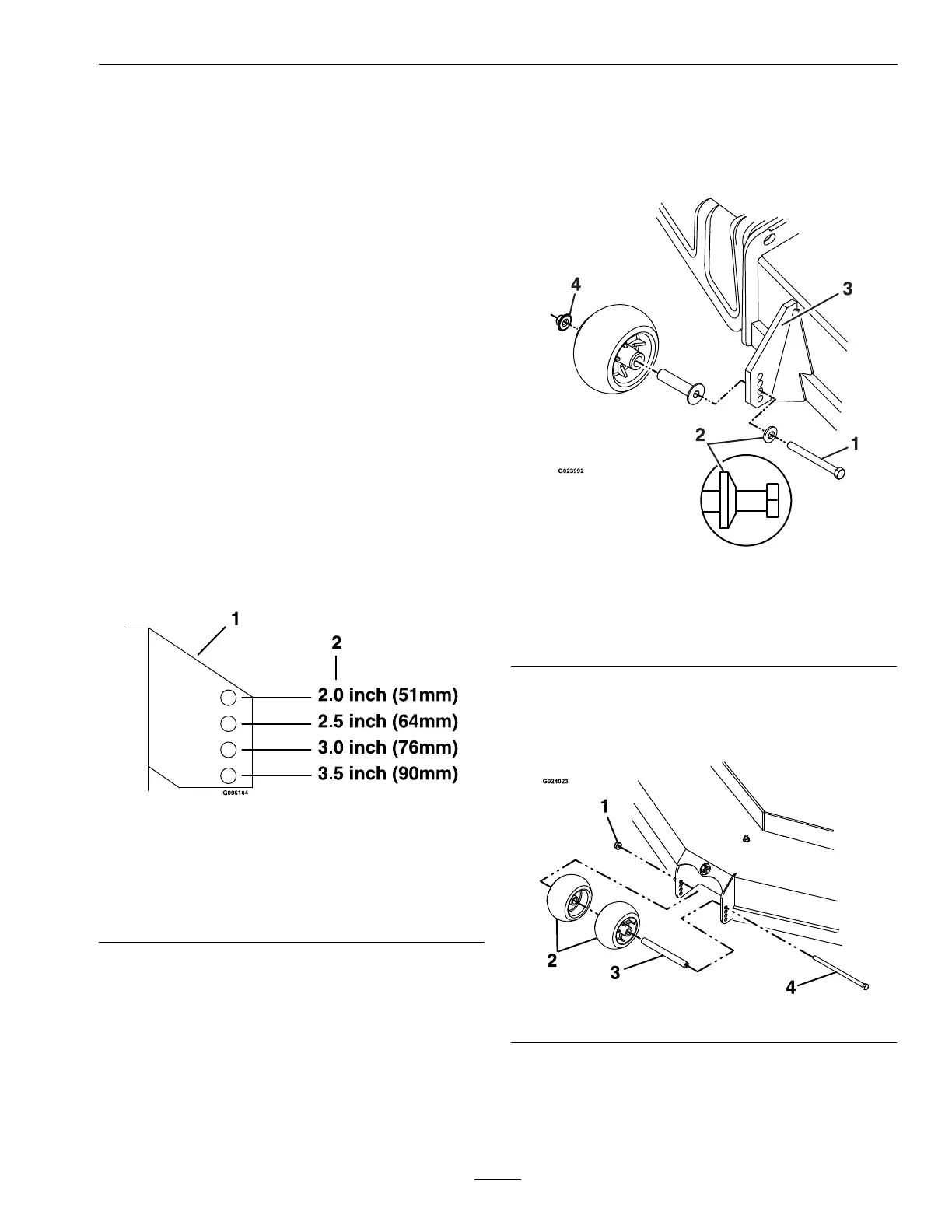

•SideDischargeUnits:

A.Besuretherollerboltsareinstalledwith

thespringdiscwasherbetweenthehead

oftheboltandthemountingbracket(see

Figure19).

B.Torquethe3/8nylocnutto50–55ft-lb

(68-75N-m).

Figure19

1.3/8-16X33/4Grade8

bolt

3.Frontrightanti-scalp

bracketshown

2.Springdiscwasher

(conetowardsbolthead)

4.3/8nyloc-torqueto50-55

ft-lb(68-75N-m)

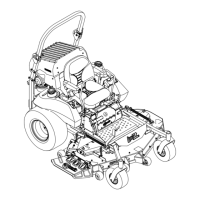

•RearDischargeUnits:

Torquethe3/8nylocnutto30-35ft-lb(41-47

N-m)(seeFigure20).

Figure20

Note:Thefootoperateddeckliftassistlevercanbe

usedtomomentarilyliftthedecktoclearobjects.Be

surethatPTOisdisengaged.

35

Loading...

Loading...