MAX300-RTG: Installation Manual Hardware Installation

37

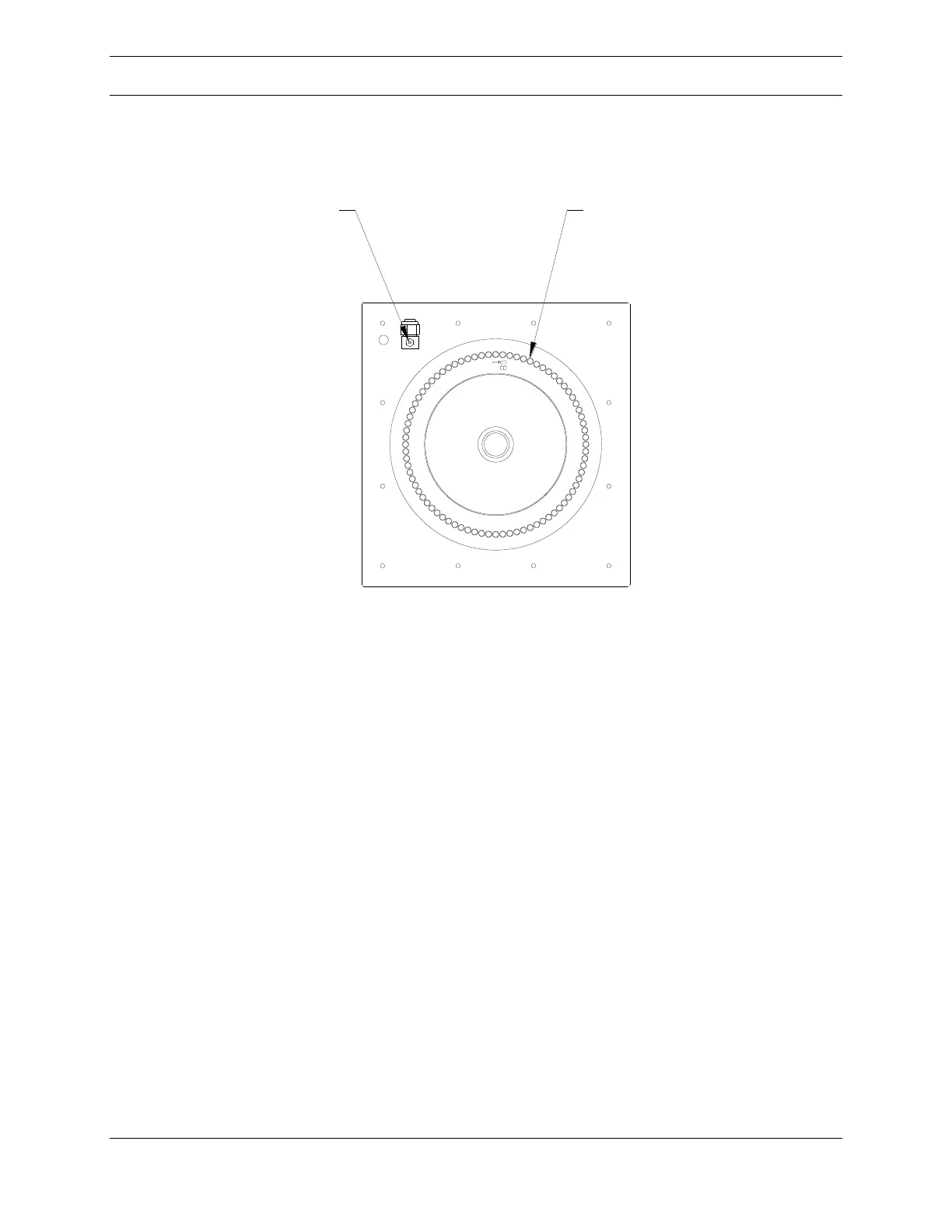

COMPRESSED AIR INLET

FOR VALVE ACTUATION ONLY

PRESSURE: 40-100 PSIG (276-690 kPa)

FLOW: 0.1 CFH (2.8 L/H)

CLEAN DRY INSTRUMENT AIR

SAMPLE FLOW REQUIREMENTS

BALANCE FLOWS WITHIN A FACTOR OF 5

VALVE BODY PRESSURE MUST NOT

EXCEED 5 PSIG (34 kPa)

Figure 17: FastValve (40/80/120/160 port valve option) – for use with

non-explosive sample

Calibration Gases

Calibration Gas Connections

The customer must connect the calibration gas cylinders to the MAX300-RTG

without contamination. Details of the connection may vary depending on the valve

option installed. Figure 18 below depicts the recommended hardware for

connecting calibration gas cylinders to the MAX300-RTG.

A common configuration is Valco rotary valves using 1/16” fittings. Each cylinder

of calibration gas requires:

High quality, low outlet pressure, two stage regulator with a stainless steel

diaphragm and appropriate CGA fitting. Please contact your gas supplier

for special considerations such as corrosive gases.

1/16" O.D. x 0.030" I.D. stainless steel tubing. Length as required to route

plumbing from MAX300-RTG to the gas storage area.

1/16" Valco nuts, ferrules, and plugs (supplied with the valve kit).

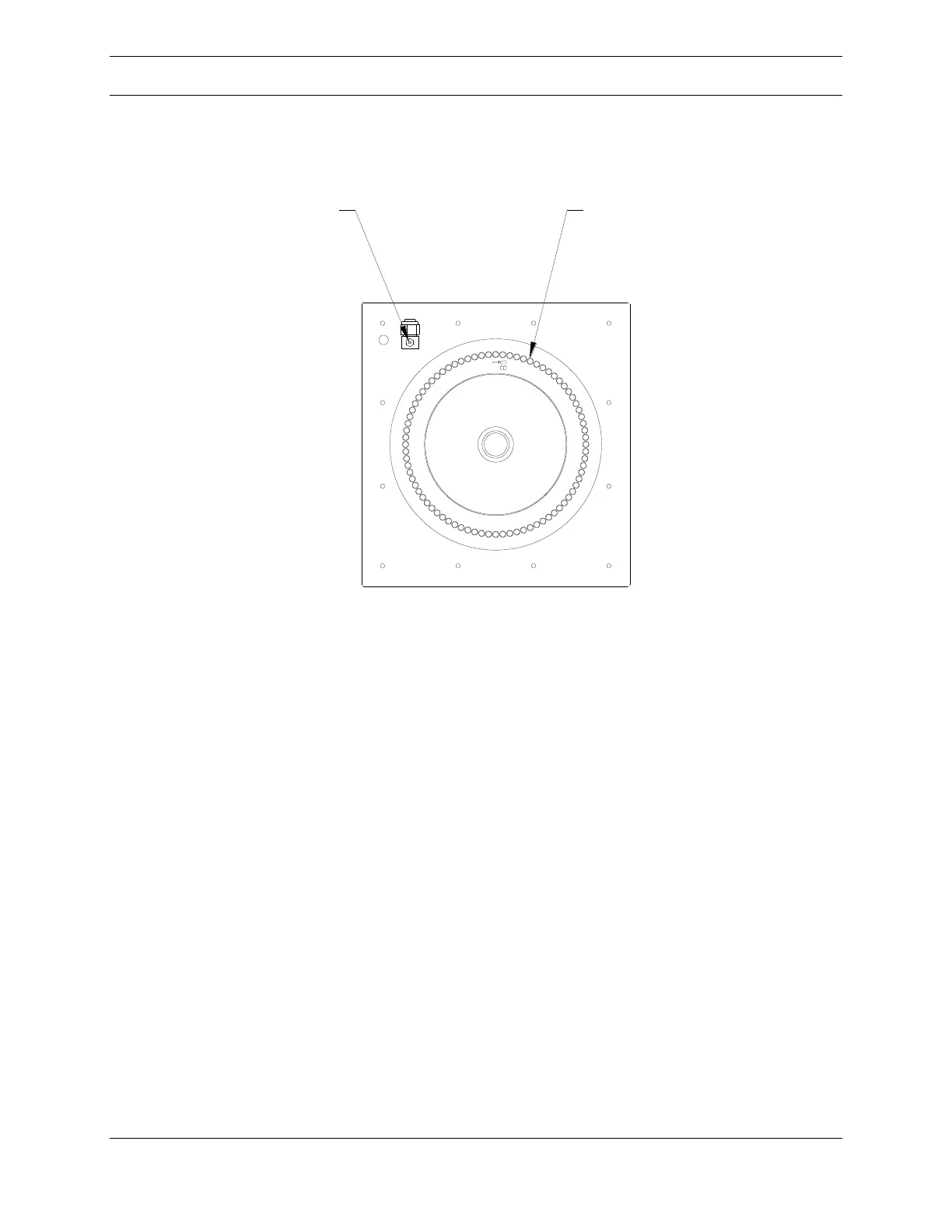

COMPRESSED AIR INLET

FOR VALVE ACTUATION ONLY

PRESSURE: 60 – 100 PSIG (414 – 690 kPa)

FLOW: 0.1 CFH (2.8L/H)

CLEAN DRY INSTRUMENT AIR

SAMPLE FLOW REQUIREMENTS

BALANCE FLOWS WITHIN A FACTOR OF 5

VALVE BODY PRESSURE MUST NOT

EXCEED 5 PSIG (34 kPa)

Loading...

Loading...