MAX300-RTG: Installation Manual Hardware Installation

50

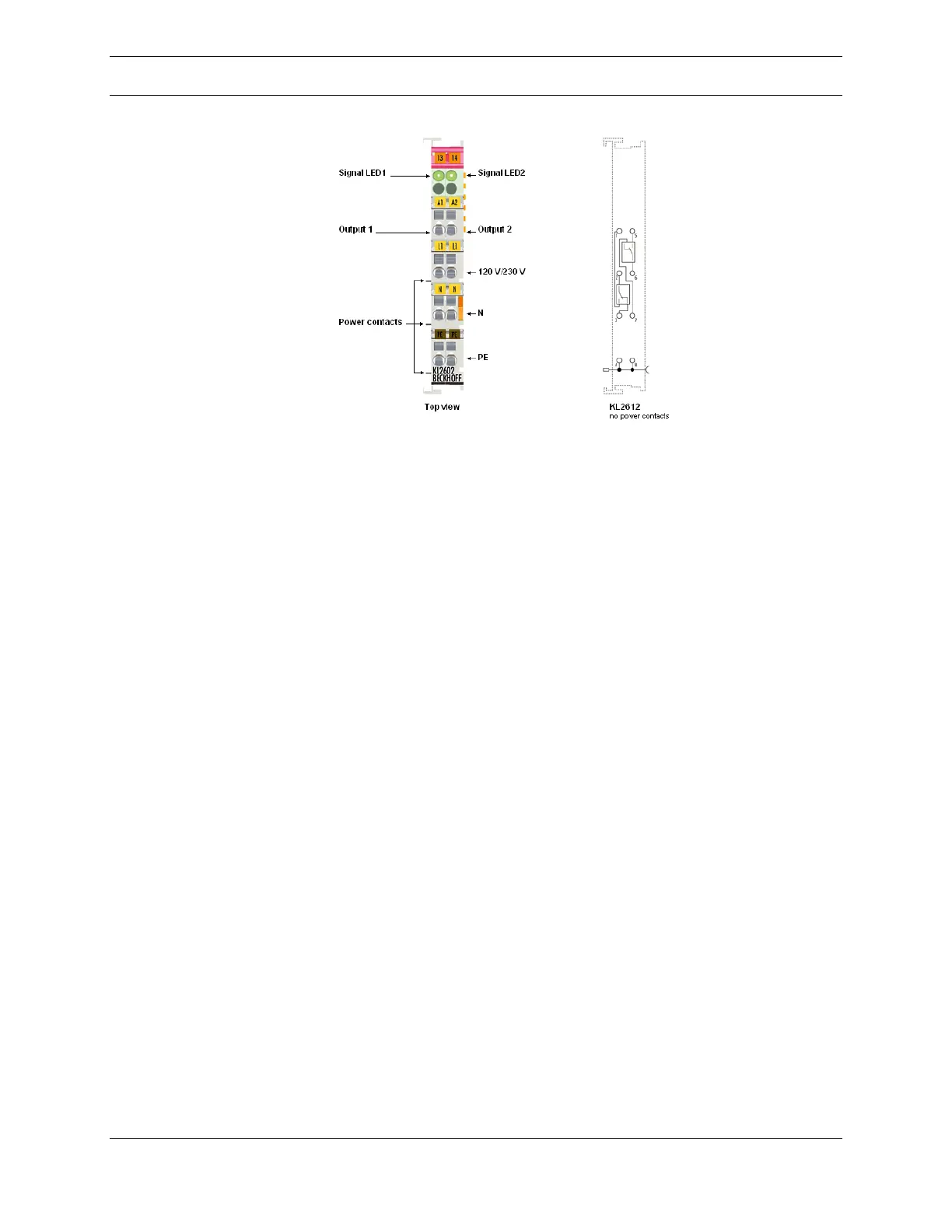

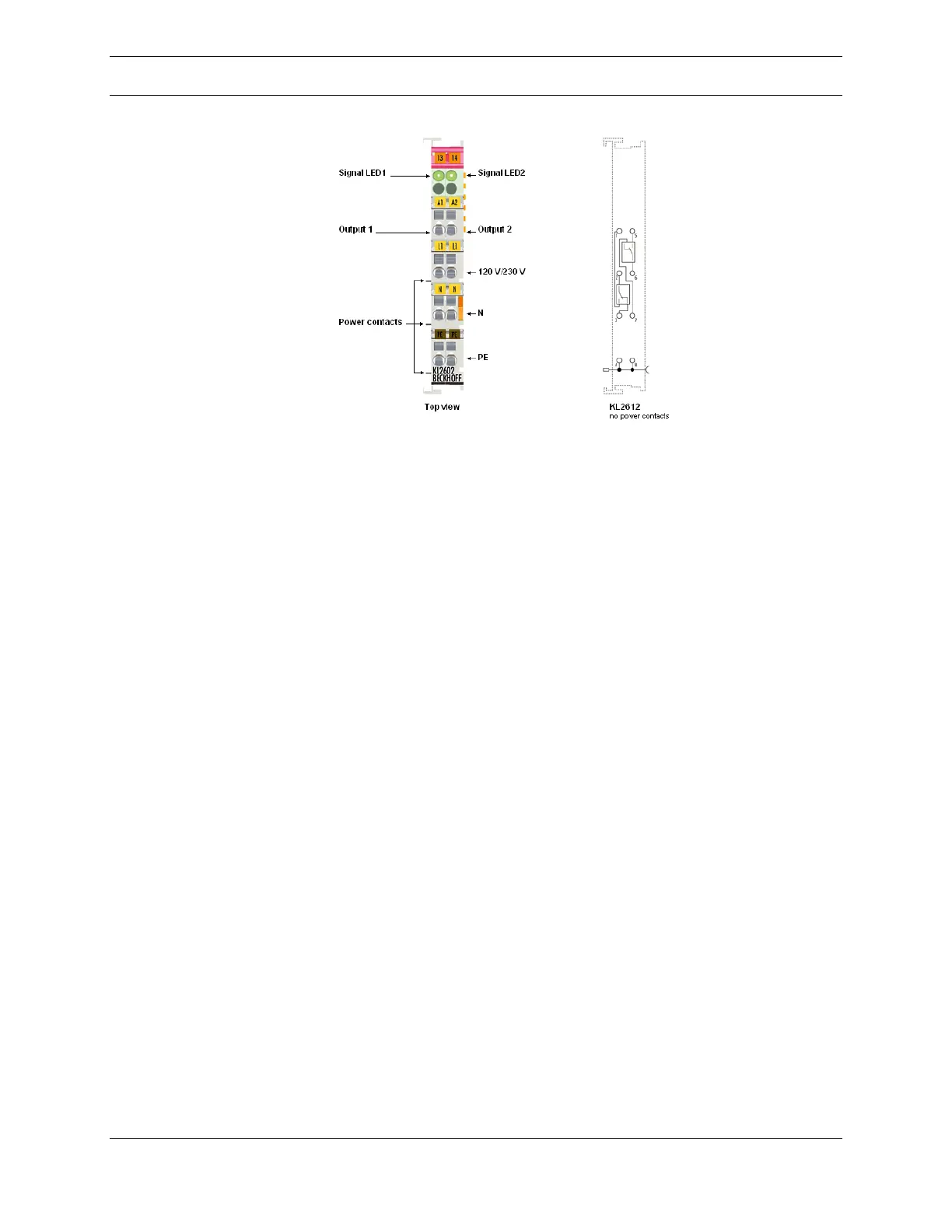

Figure 26: KL2612 Output Terminal

Distributed Control System (DCS)

The DCS, Distributed Control Systems, communications option enables the

MAX300-RTG to be controlled by way of digital input from a user’s industrial

process control system. DCS will assign a number as “script” of MAX300-RTG

actions to be implemented when received. The standard implementation for DCS

is via the Digital Input modules in the 4-20mA and Digital I/O options.

External control of the operation of the MAX300-RTG is accomplished through the

use of the DCS option. When this option is implemented, the Questor5 software

may be configured so that steps in a pre-programmed sequence are commanded

by the value of an input parameter, i.e. a trigger. The MAX300-RTG’s Questor5

software may be configured to use one, or several, of seven different types of

triggers.

Digital Inputs

Analog Inputs

OPC Inputs Tags

Modbus Slave Holding Registers

Modbus Slave Coil Status

Modbus Master Holding Registers

Modbus Master Coil Status

The DCS option is implemented at the factory by modifying internal configuration

files to reflect the purchase of the DCS control option and by installing the

appropriate optional control hardware. Additional hardware is required for all DCS

control sources noted above except for OPC. In the case of digital and analog

inputs, the Beckhoff Bus Terminal and appropriate input and output terminals

needed to be installed in the MAX300-RTG in addition to a serial port in the server

Loading...

Loading...