37X INSTALLATION & OPERATION MANUAL

372/373 MODELS

12

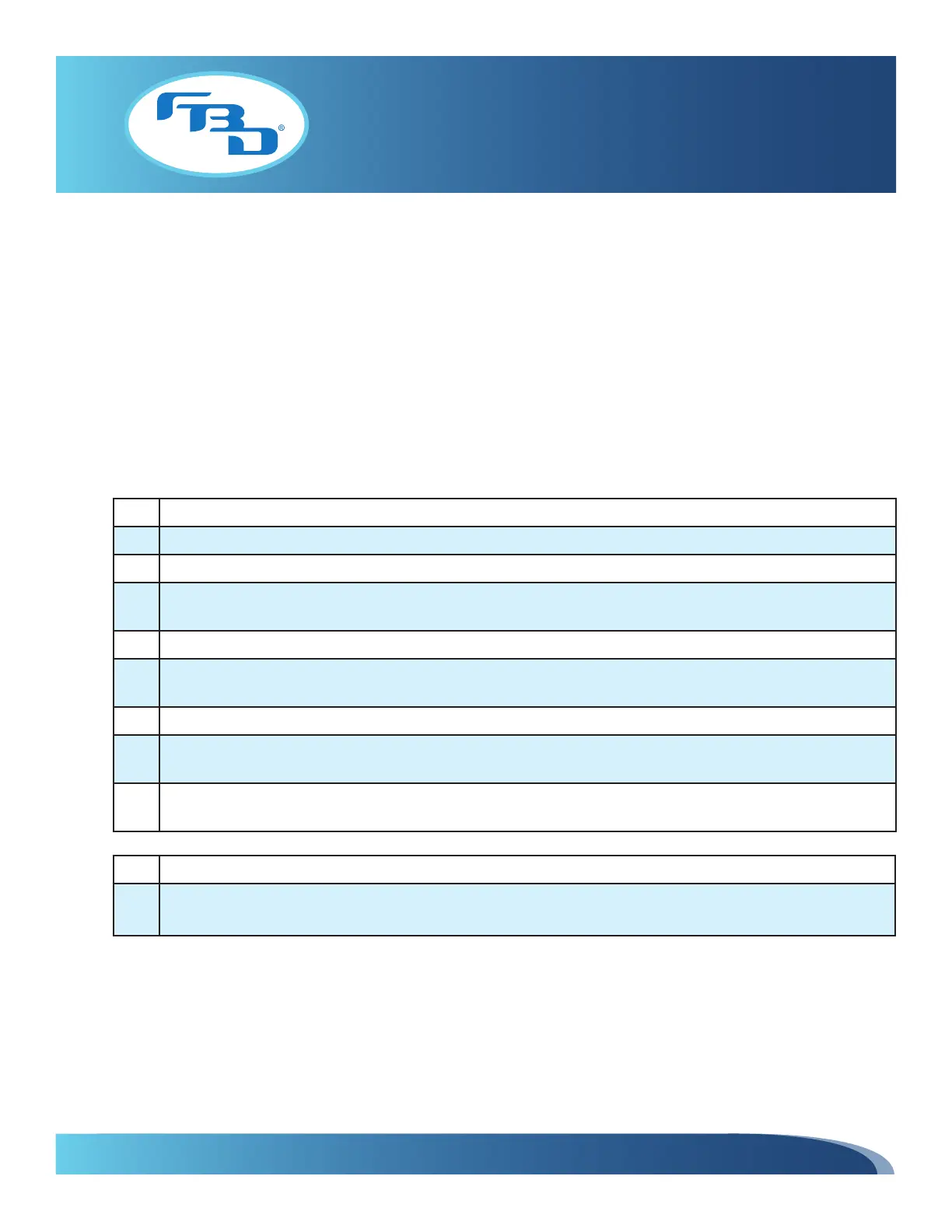

5.2 Initial Power Up

Plug the dispenser into the power supply and verify the dispenser turns on by looking at the LCD located behind the

merchandiser. Some models are equipped with an on/off switch; ensure the switch is in the ON position. The display

should be on the home screen showing the status of the barrels (see Section 7 for additional information on keypad

buttons and how to navigate through menus). If the firmware has just been updated, then the dispenser will prompt the

operator to answer the following questions:

1. Desired language.

2. Dispenser serial number.

3. Dynamic charge control.

4. Number of barrels.

After responding to the prompted questions, the home screen will be displayed.

Next, a few verifications will need to be made:

For multi-flavor dispensers, the following will also need to be completed:

Note: The voltage drop on the LCD between idle and run modes must not exceed 10 volts between the power source and

the machine. If it is greater than 10 volts then the power supply is inadequate and needs to be addressed by a certified

electrician.

† Use the display pressure readouts when adjusting the settings.

‡ The water pump output pressure should be 15 to 20 PSI (103 to 138 kPa) above the unregulated gas (or “Main Gas”)

pressure. See the troubleshooting section (Section 10) if the pressures are not correct.

§ The dispenser will automatically compensate for fluctuations in regulated gas (or “Gas #1”/”Gas #2”) from 50 to 70 PSI

(345 to 483 kPa). Ensure that during setup the regulated gas is set as close to 60 PSI (414 kPa) as possible.

1 Press the green check button and then select the MENU option. Next, select the READOUTS option.

2 Press the COMMON button.

3 Verify the line voltage is at 230V ± 10%.

4

Verify the unregulated gas pressure (or "Main Gas" for universal and multi-gas congurations) is

between 70 to 72 PSI (483 to 496 kPa)

†

and adjust the external or backroom regulator if needed.

5 Verify the water pressure is between 85 to 92 PSI (586 to 634 kPa)

†

. This is not adjustable.

‡

6

Verify the regulated gas pressure (or "Gas 1"/"Gas 2" for universal and multi-gas congurations) is

approximately 60 PSI (414 kPa) and adjust the internal regulator(s) if needed.

§

7 Press the BARREL button.

8

Verify the syrup pressures are between 70 to 72 PSI (483 and 496 kPa) and adjust the back room

regulator if needed.

9

Dispense product from the sample valve after adjusting any pressures. This will restabilize to the

new pressure.

10 Press the FLAVOR button in the READOUTS menu.

11

Verify the syrup pressures for each of the avors are between 70 and 72 PSI (483 and 496 kPa) and

adjust the regulator if needed.

Loading...

Loading...