37X INSTALLATION & OPERATION MANUAL

372/373 MODELS

13

Water Flow

Control

Syrup Flow

Control

5.3 Water Flow Rate and Brix

The water flow rate and brix for each barrel must be verified and adjusted for optimal performance. Use the following

procedure to adjust the water flow rate and set the brix for each barrel:

For multi-flavor dispensers, the flavor injection modules will also need to be calibrated. Please refer to the Multi-Flavor

Merchandiser Manual (24-M4MF-0001) for the calibration procedure.

The target brix for most sugar flavors is between 13.5 and 15. The target brix for most “light” flavors will be lower, usually

between 9 and 10. Check the specifications for the flavors if unsure of the target brix

Note: Light or diet products have a low brix and can cause problems with the dispenser if not properly set up. Although

these products contain ingredients that ensure the sugars freeze, they can still create excessive ice if not carefully brixed

according to their specifications. Low brix issues will be associated with events such as audible ice scraping during freeze

and low beater error problems.

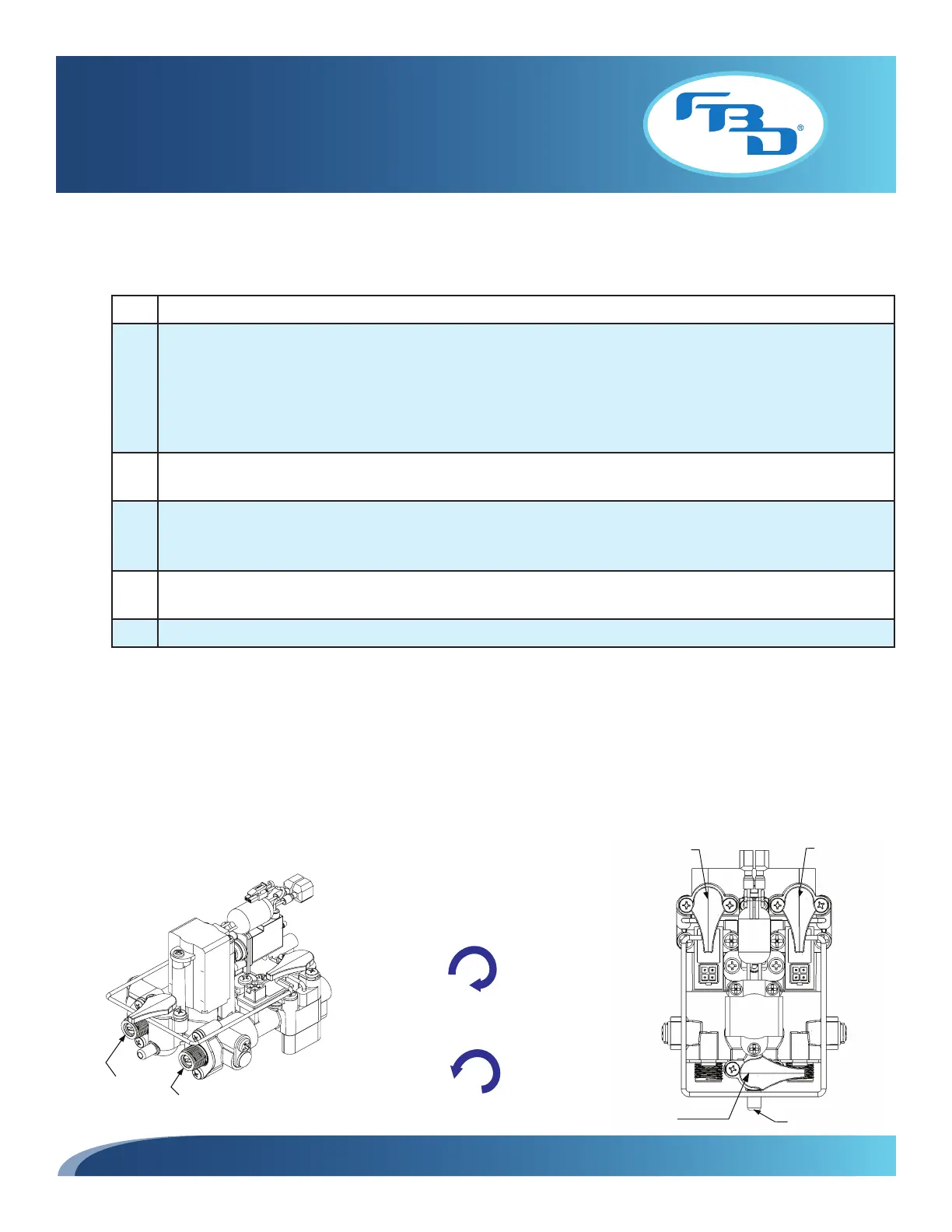

1 Turn the syrup shuto valve to the OFF position (Figure 5.2).

2

Adjust the water ow rate to 1.5 oz/sec (44.4 ml/sec) by dispensing water from the solution module

through the sample port for 10 seconds into a measuring cup. The amount measured should

be 15 oz (444 ml). Turn the ow control clockwise to increase the ow and counterclockwise to

reduce the ow.

Note: The WATER AND BRIX CALIBRATION screen under the MAINTENANCE MENU can be used to

help with timing.

3

Turn the syrup shuto valve to the ON position and dispense a cup of uid from the sample port

to establish a stable ow.

4

Once a good water and syrup mixture is obtained, dispense a 16 oz sample and measure the

sample brix with a refractometer. Be sure to thoroughly mix the sample rst by pouring back and

fourth between two cups.

5

Turn the syrup ow control counterclockwise to decrease the brix. Turn the syrup ow control

clockwise to increase the brix.

6 Dispense and discard several samples after adjusting the brix.

Sample Port

Sample Valve

(closed position

shown)

Water Shutoff

Valve (open

position shown)

Syrup Shutoff

Valve (open

position shown)

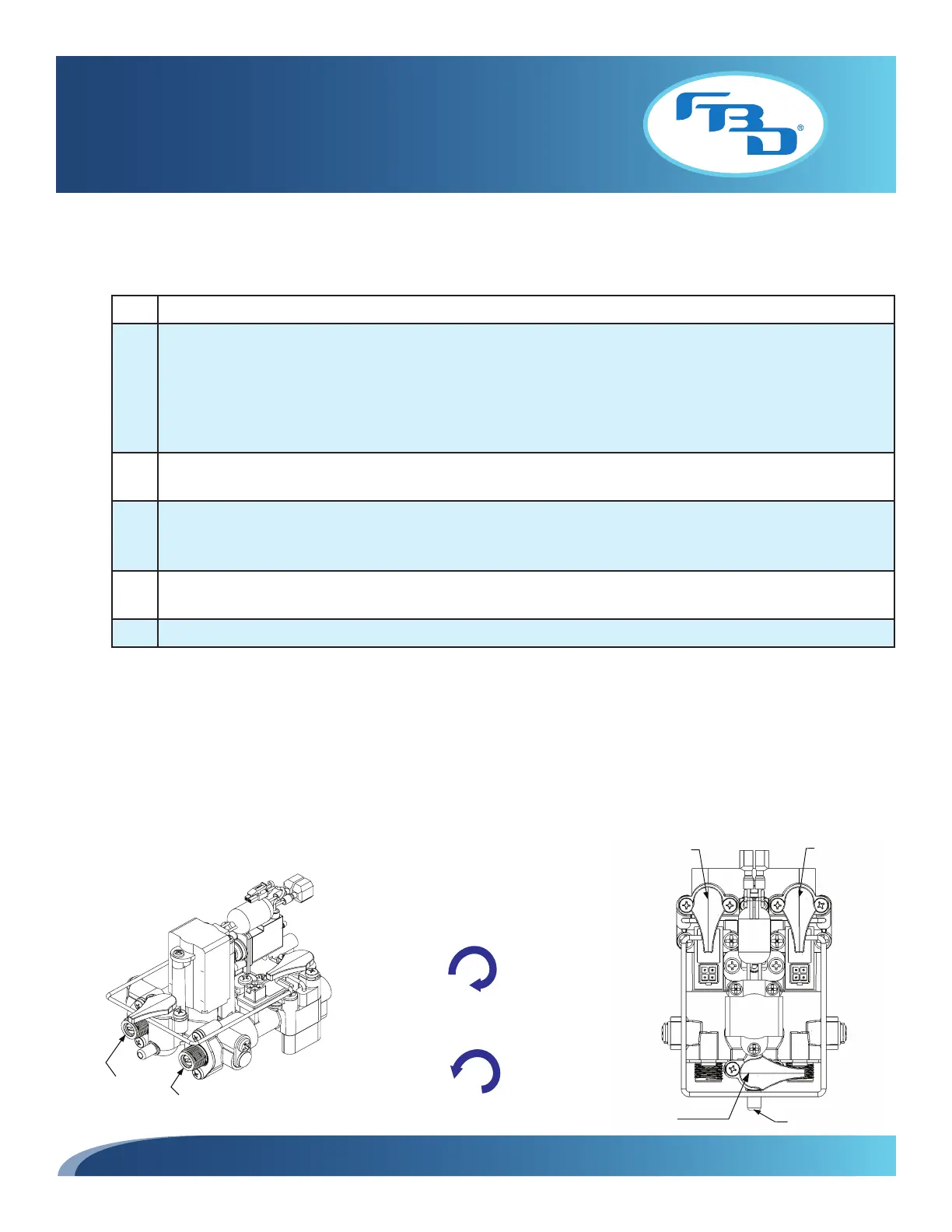

Turning Clockwise

Increases Flow Rate

+

–

Turning Counterclockwise

Decreases Flow Rate

Flow Rate Adjustment

Figure 5.2 Solution Module

Loading...

Loading...