37X INSTALLATION & OPERATION MANUAL

372/373 MODELS

7

Countertop - Leg Mounting: Another countertop option is to install 4" support legs (sold separately) to allow for easy

cleaning around and under the dispenser. The legs install easily into the same four holes used to bolt the frame to the

shipping pallet. As an added benefit, this installation typically meets state and local health department codes.

Base Cart: A roll-around base cart (sold separately) can be used when a suitable countertop location is not available.

Dispensers installed to base carts must be bolted to the cart to avoid the dispenser from falling off which could result in

serious injury or death. Once installed, seal the dispenser to the cart using a bead of clear silicone caulk around the base

of the frame.

4.3 Self-Contained Refrigeration Models

Adequate clearance around the dispenser is required for proper air flow. Failure to provide proper clearance will reduce

capacity and can damage the refrigeration system. See the specifications page for clearance requirements. Avoid enclosed

installations if possible; recirculated hot discharge air from the dispenser can impact performance or damage the system.

Such installations require supplemental ventilation such as a fan with a thermal switch to remove the hot discharge air.

An ambient temperature of no more than 75°F (24°C) provides the optimal capacity. As the ambient temperature increases,

the dispenser capacity decreases. It is essential that the HVAC system be sized to handle the additional heat load from all

self-contained, air-cooled dispensers.

4.4 Universal Gas and Multi-Gas Configurations

Some 372 dispensers are equipped with FBD's Multi-Gas (372 standard dispensers) or Universal Gas (372 multi-flavor

dispensers) feature. Multi-Gas dispensers have two gas connections—one drives the pump and active charge system, and

the other injects gas into the product. Universal Gas dispensers have three gas connections—one drives the pump and

active charge systems, a second injects gas into the product in barrel 1, and a third injects gas into the product in barrel

2. This feature allows the user to configure the drink profile for each barrel and is available on all 372 multi-flavor (MFLV)

dispensers.

Main Gas: The gas fed to the Main Gas connection operates the dispenser’s pneumatic components (the water pump,

active charge, and any pneumatic faceplates). Compressed air, CO

2

, or N

2

can be used as the dispenser’s Main Gas.

Gas 1 (372 and 372 MFLV) and Gas 2 (372 MFLV only): The gas (CO

2

, or N

2

) fed to the Gas 1 and Gas 2 connection is

injected into the drink in the respective barrel.

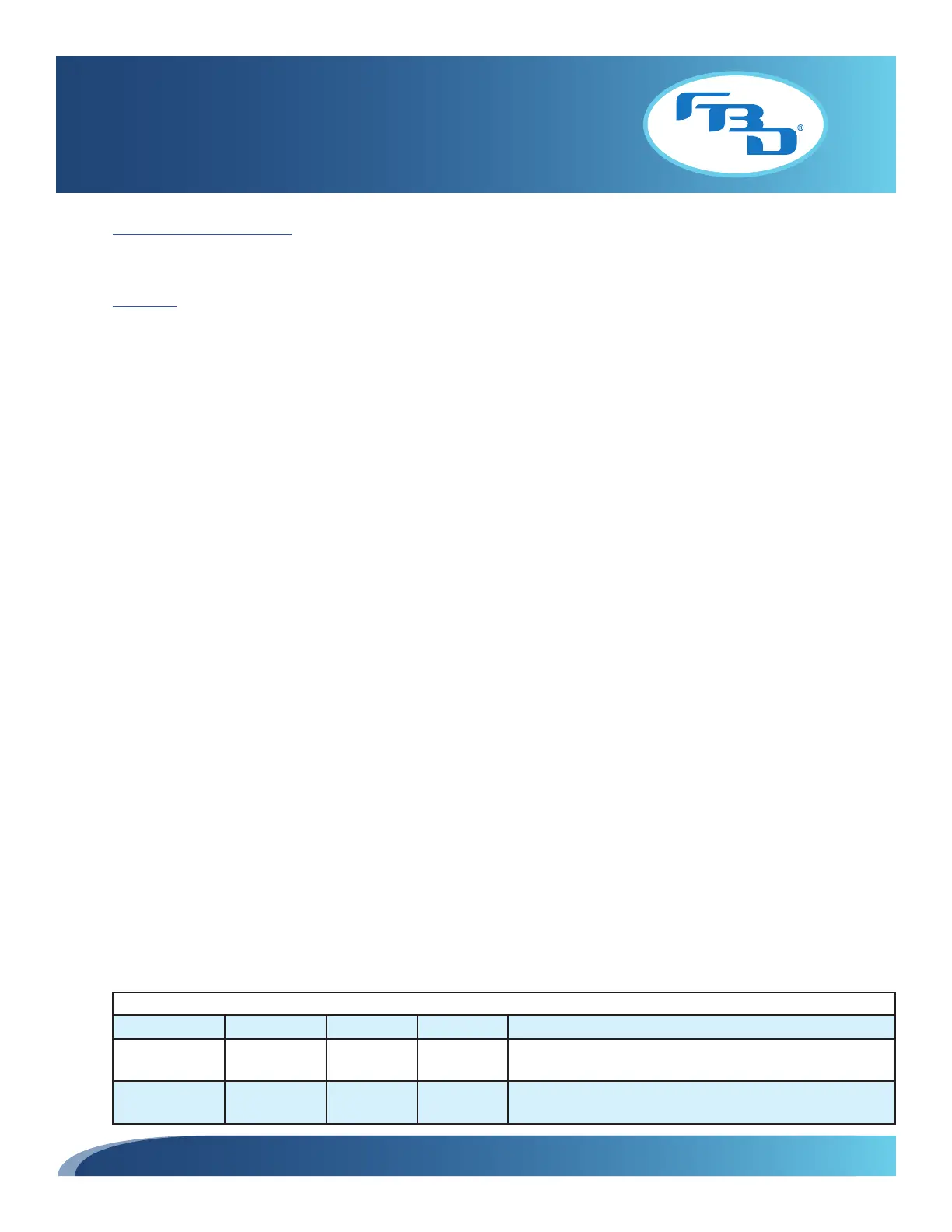

The Universal Gas setup allows the operator to adjust the levels of Gas 1 and 2 injected into the drink (a drink's expansion

refers to the amount of gas injected). The table below lists the available drink types depending on which gas is selected

for Gas 1 or Gas 2 (where applicable). Please refer to Section 4.6 for additional information related to gas connections for

the dispenser and Section 7.10 for instructions on configuring drink types.

Universal and Multi-Gas Conguration Drink Types

Dispenser Main Gas Gas 1 Gas 2 Available Drink Types

372 Standard

Multi-Gas

CO, N, or Air CO or N N/A

CO: High Expansion

N: Medium Expansion

372 Multi-Flavor

Universal Gas

CO, N or Air CO or N CO or N

CO: Medium Expansion and High Expansion

N: Medium Expansion

Loading...

Loading...