28

!

"

#

$

"

Bandsaw

FB 540/640/740/840/940

7.4.5 Direction of cut and parallelism

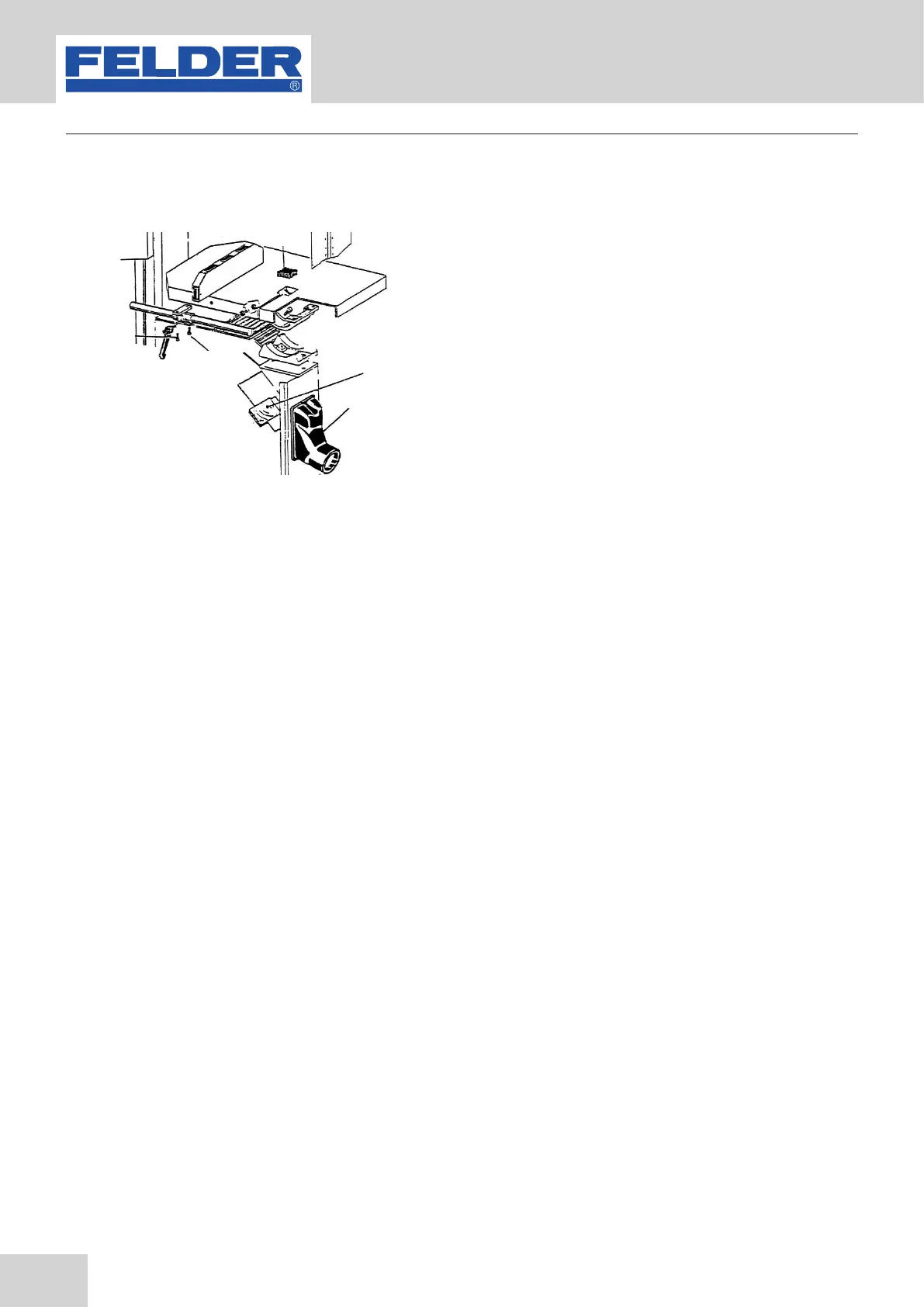

7.4.4 Table pad and wooden pad for dust extraction

The machine is equipped with a plastic table pad. The

holes in this pad facilitate the task of extracting dust. The

height of the table padding can be adjusted exactly to

table level with the 4 adjusting screws in the table open-

ing. Machines with a wheel diameter of up to 600 mm

only have one dust extraction port.

Machines with a larger wheel diameter, have a second

dust extraction port, located at the front of the machine,

below the working table. To maintain the extraction ca-

pacity, change the wooden pad if the cutting gap is get-

ting too large.

Fig. 22: Table insert and Wooden pad

!Wooden pad

"Dust extraction holes

#Vacuum connection

$Clamping screws

If the cut, using the longitudinal stop, is still not parallel,

the following are possible causes:

• Incorrect saw belt grinding and set

• Insufficient saw belt tension

• Incorrect longitudinal stop setting in relation to the

saw belt. To adjust the parallelism, loosen the 2

clamping screws, readjust the parallelism and tighten

the clamping screw.

Operation

Loading...

Loading...