29

3. To re-install the floor pan: Reverse the removal

procedure.

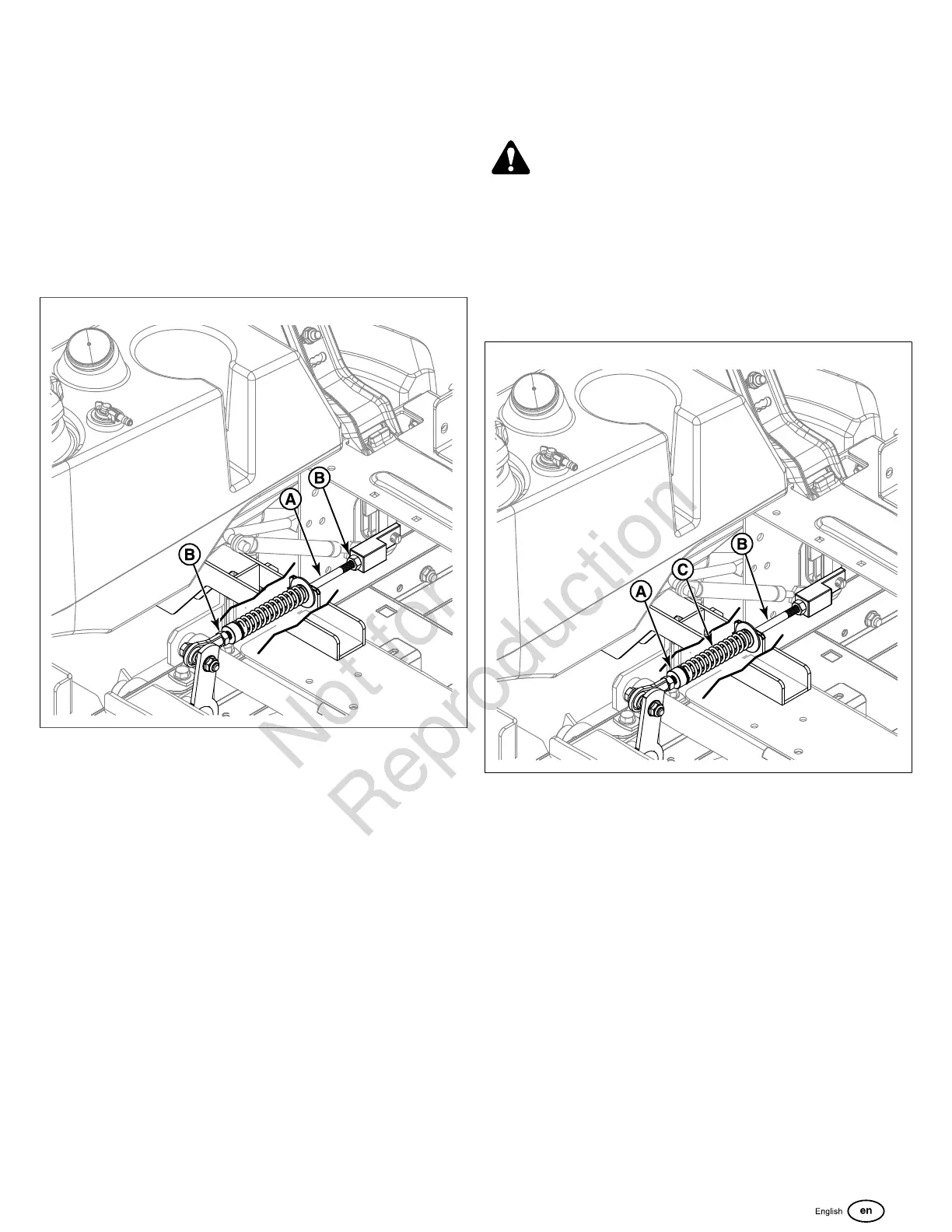

Neutral Adjustment

Each ground speed control lever on this machine is

connected to a transmission by two linkage rods and a

pivoting arm. The lower rod that connects the transmission

to the pivoting arm is set at the factory and should not be

changed for neutral adjustment purposes. The neutral

adjustment is achieved by changing the length of the upper

linkage rod (A, Figure 39) that connects the ground speed

control lever to the pivoting arm.

39

Determining if adjustment is necessary:

Lock the ground speed control levers in the NEUTRAL

position. If either of the zero-turn rider’s tires turns; then the

upper linkage rod associated with that side of the machine will

need to be adjusted.

Note:Perform this adjustment on a hard, level surface such

as a concrete floor.

1. Disengage the PTO, engage the parking brake, and turn

off the engine.

2. There are two nuts (B) on the upper linkage rod. Loosen

the nuts and turn the upper linkage rod to adjust.

• If the machine creeps forward, turn the upper linkage

rod clockwise (while standing at the rear of the

machine, facing forward);

• If the machine creeps backward, turn the upper

linkage rod counter-clockwise (while standing at the

rear of the machine, facing forward).

3. Lock the jam nuts when neutral is achieved.

Note:This adjustment should not be performed while the

machine is running. It may take several attempts to achieve

neutral, depending on how much the machine creeps.

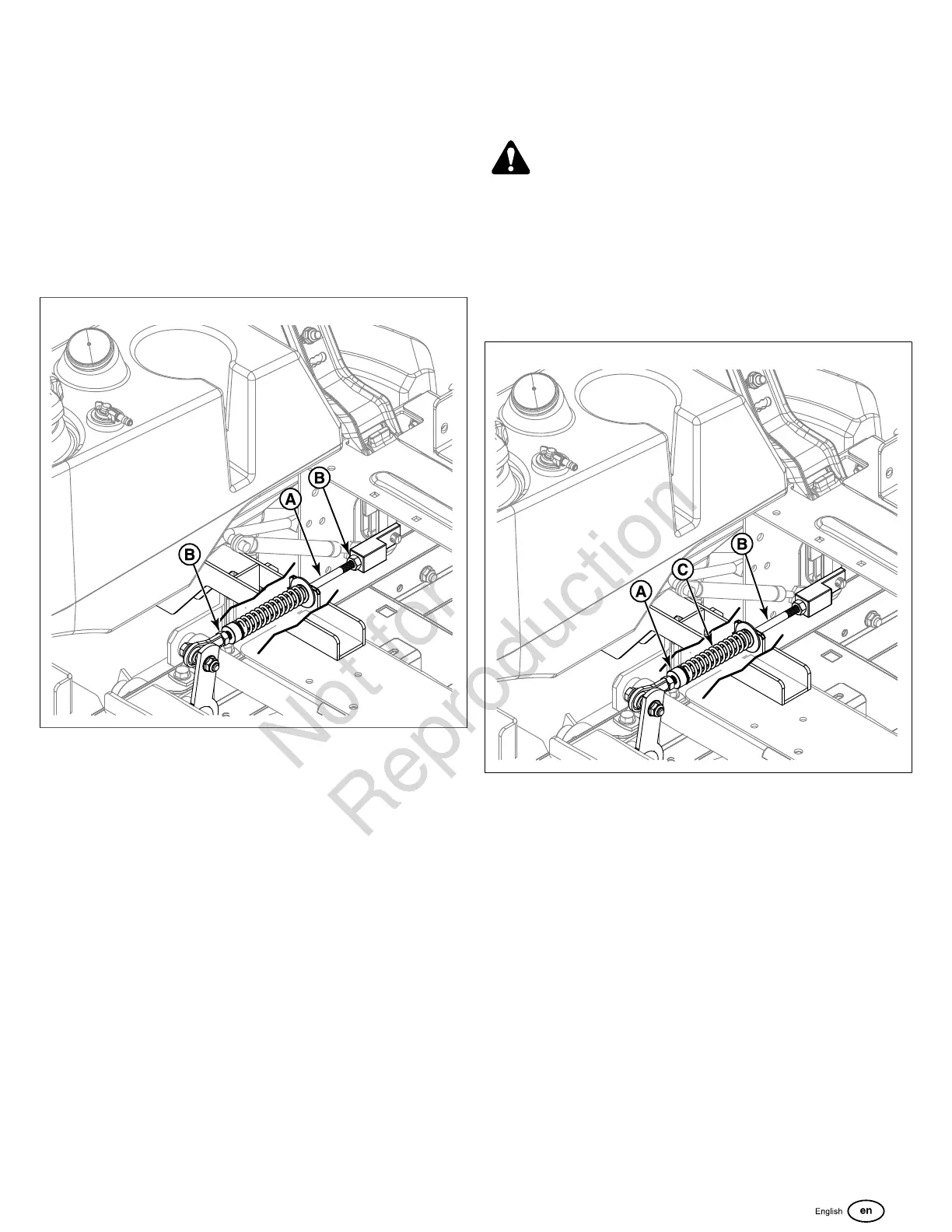

Return-to Neutral Adjustment

Prior to performing this procedure the Neutral Adjustment

procedure must be completed.

WARNING

To avoid serious injury, perform adjustments only with

engine stopped, key removed, and rider parked on level

ground.

1. Position the ground speed control levers into the

NEUTRAL position.

2. Loosen the set collar (A, Figure 40) on the upper linkage

rod (B).

40

3. Position the set collar along the upper linkage rod until it

contacts and very lightly compresses the neutral return

spring (C).

4. Move the ground speed control levers into the operating

position, pull rearward, and release.

5. Move the ground speed control levers out towards the

NEUTRAL position.

• if the ground speed control lever aligns with the notch

in the neutral lock plate, adjustment is complete;

• if the ground speed control lever stops it's return

motion past the notch (while standing at the rear of

the machine), re-position the set collar so the neutral

return spring is less compressed.

• if the ground speed control lever stops it's return

motion before the notch (while standing at the rear

of the machine), re-position the set collar so that the

neutral return spring is more compressed.

6. Repeat the process as necessary until the ground speed

control lever aligns with the notch in the neutral lock plate.

Loading...

Loading...