31

27

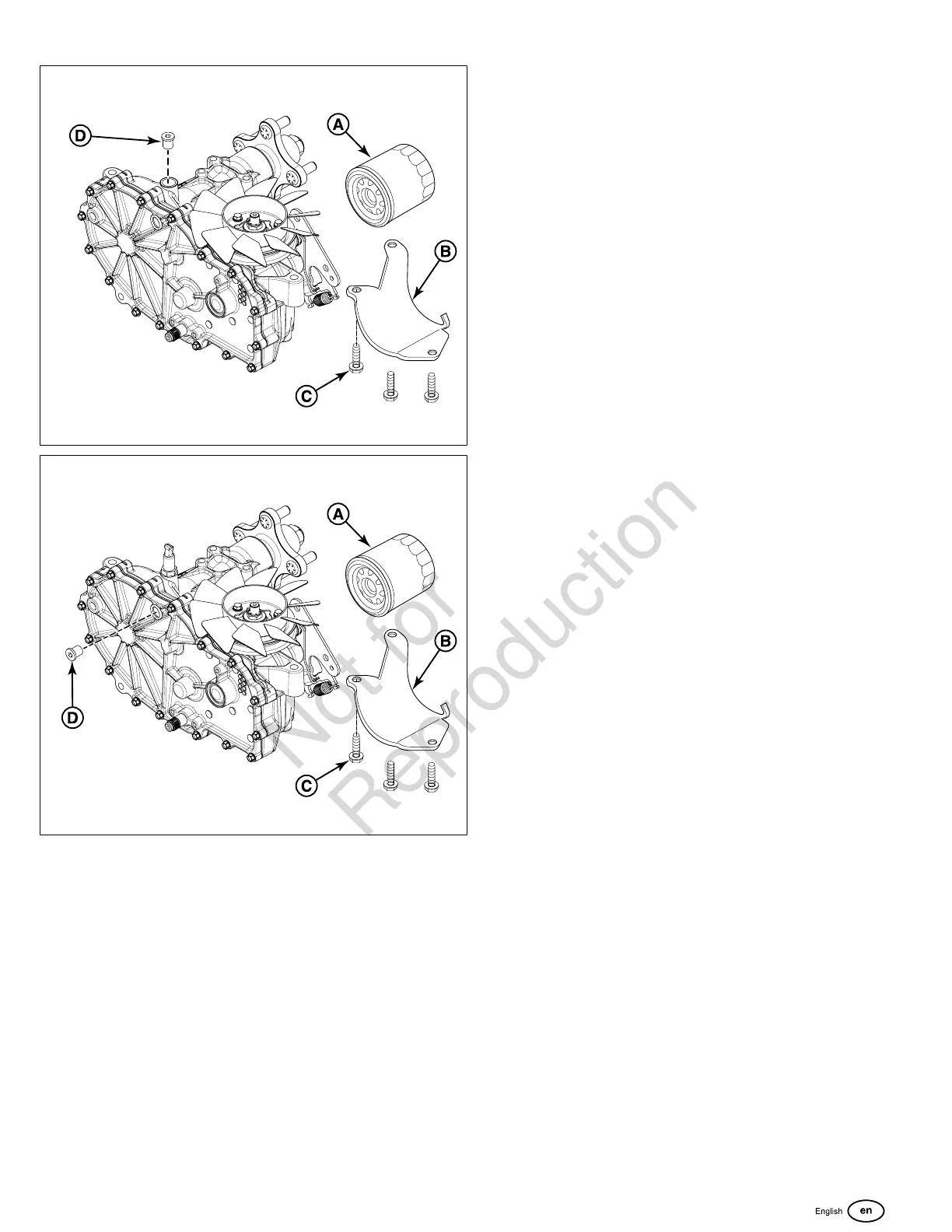

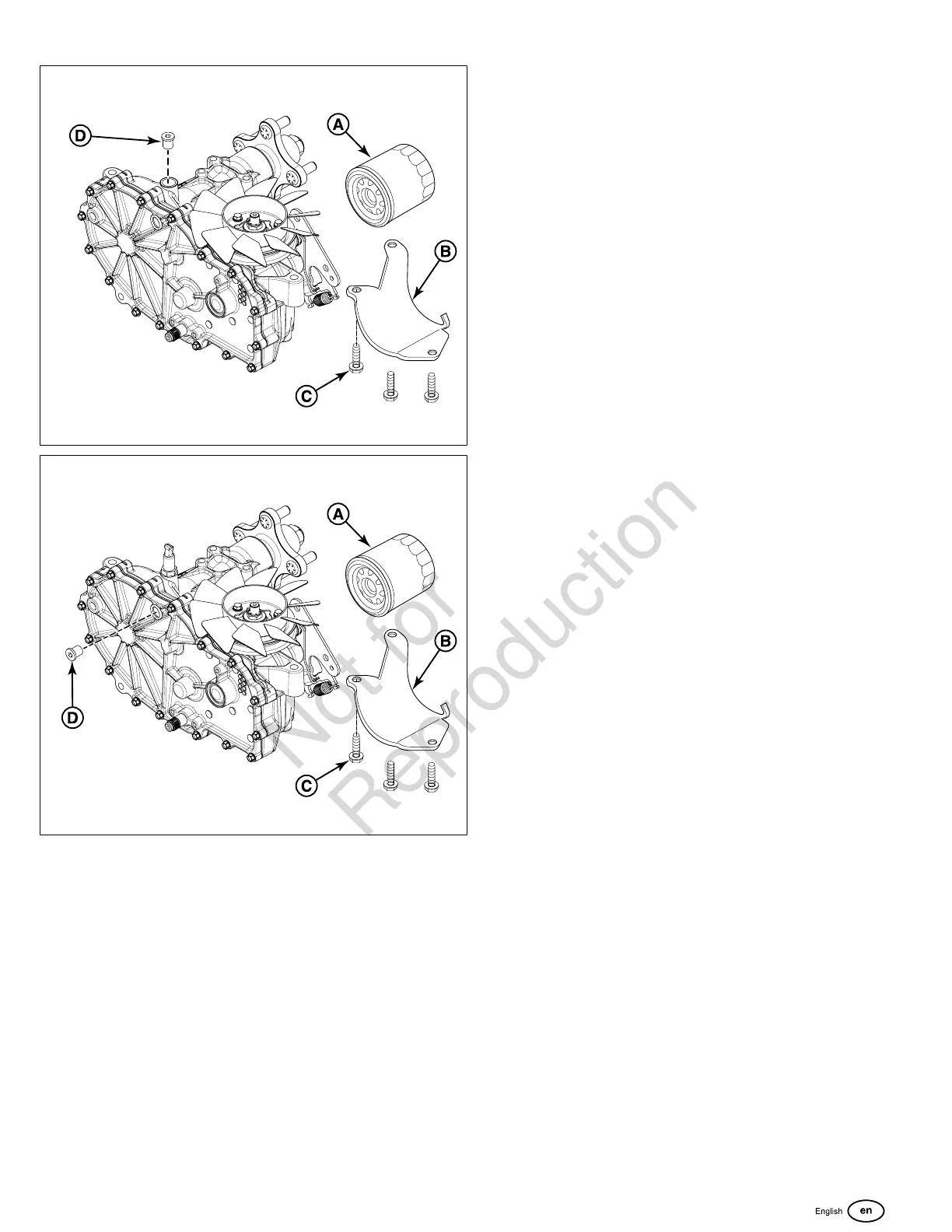

28

2. Remove the three 1/4” filter guard screws (C) and the

filter guard (B).

3. Clean the area around the filter base and remove the

filter.

4. Apply a film of new oil to the gasket of the new

replacement filter. After the oil has drained, thread the

new filter onto the filter base until the gasket makes

contact, then tighten 3/4 of a turn more.

5. Reinstall the filter guard with the three 1/4” filter guard

screws.

6. Locate the port plug (D) on your transmission.

• If your unit has hydraulic hoses that connect to the

side of the transmission then the port is located

on the top of the transmission. See Figure27for a

reference to the port location.

• If your unit has hydraulic hoses that connect to the

top of the transmissions then the port is located on

the side of the transmission. See Figure28for a

reference to the port location.

7. Using a hex bit swivel socket or a modified allen wrench

remove the top port plug from the transmissions.

8. Remove the transmission oil tank cap and fill with oil

until oil appears at the bottom of the transmission’s port

(approximately 2 qts (1,89 L).

9. Reinstall the port plug and tighten to 15 ft lbs (20,38 Nm).

10. Continue to add oil to the transmission oil expansion tank

until the oil level reaches the “FULL COLD” mark. Put the

transmission oil tank cap back on and hand tighten.

11. Repeat this process for the other side of the machine.

12. Perform thePurging the Air from the Hydraulic

Systemprocedure.

Purging the Air from the Hydraulic

System

Due to the effects air has on efficiency in hydraulic drive

systems, it is critical that it be purged from the system.

These purge procedures should be implemented any time a

hydraulic system has been opened to facilitate maintenance

or any additional oil has been added to the system.

The resulting symptoms of air in the hydraulic system may be:

• Noisy operation.

• Lack of power or drive after short term operation.

• High operation temperature and excessive expansion of

oil.

Before starting, make sure the transaxles/transmissions are

at the proper oil levels. If it is not, fill to the specifications

outlined in the Check / Fill Transmission Oil Level procedure.

Purging Air from the Hydraulic System:

1. Chock the front wheels to prevent the unit from rolling.

Raise the rear of the unit so that the unit's rear tires do

not contact the ground. Position jack stands under the

rear bumper of the unit to secure it.

2. Open the transaxle’s bypass valves (see Pushing the

Unit by Hand for the location and function of the bypass

valves), start the engine, release the parking brake, and

slowly move the unit’s ground speed control levers in both

forward and reverse directions (5 to 6 times), as air is

purged from the unit, the oil level will drop.

3. Stop the engine and engage the parking brake.

4. Close the transaxle’s bypass valves, start the engine,

release the parking brake, and slowly move the unit’s

ground speed control levers in both forward and reverse

directions (5 to 6 times), as air is purged from the unit, the

oil level will drop.

5. Stop the engine. Remove the jack stands from

underneath the unit.

Loading...

Loading...