CLR

4 Festo – CLR – 2017-05e English

2 Function

When the compressed air connections are

pressurized alternately, the piston rod of the

linear-swivel clamp type CLR-... moves in and

out. On the piston rod there is a guide sleeve

with three different grooves. A guide bolt in

the housing grips into the groove. By means

of the special shape of the grooves, the bolt

transfers the following movements to the

piston rod:

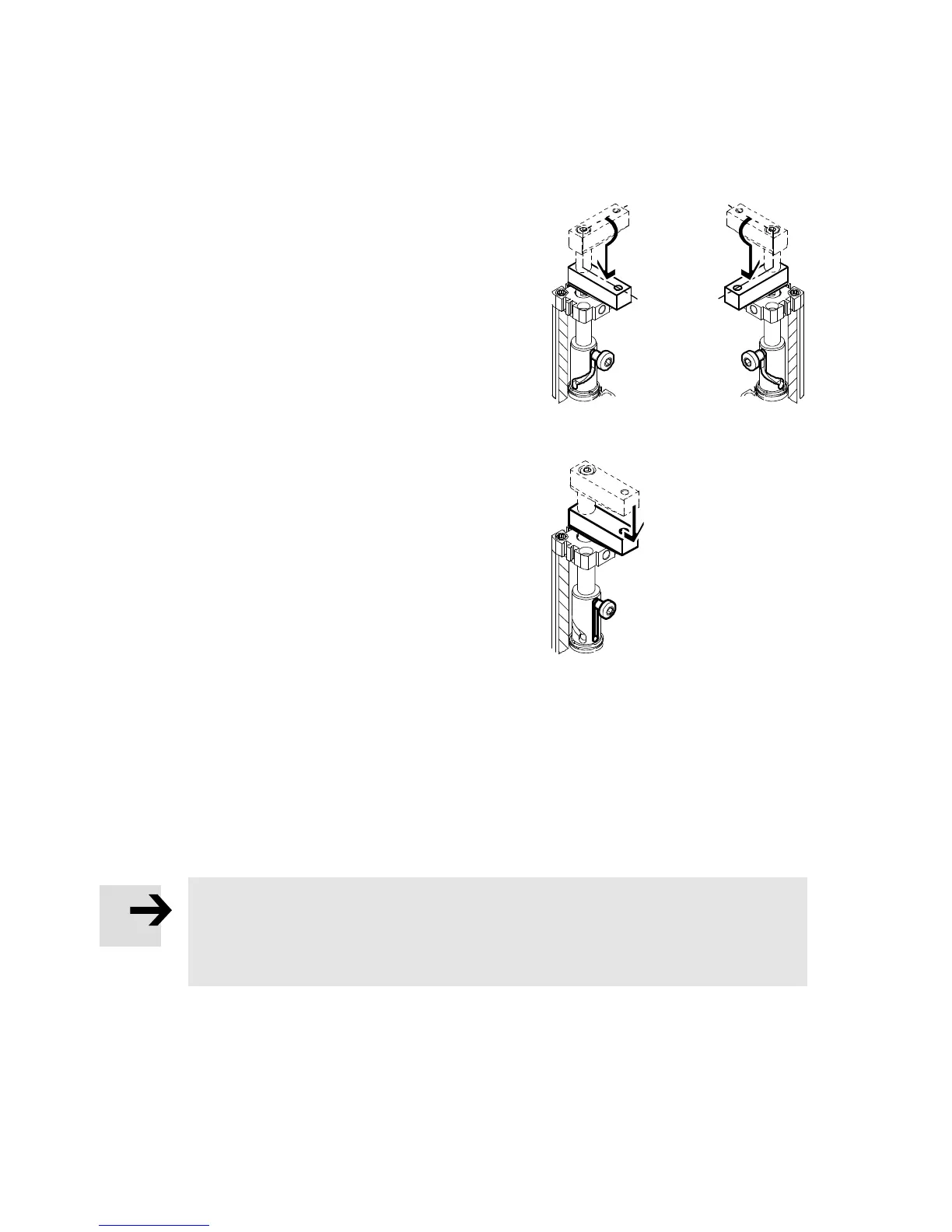

– swivel-linear movement of 90° in a

clockwise direction (Bild 2)

– swivel-linear movement of 90° in an anti-

clockwise direction (Bild 3)

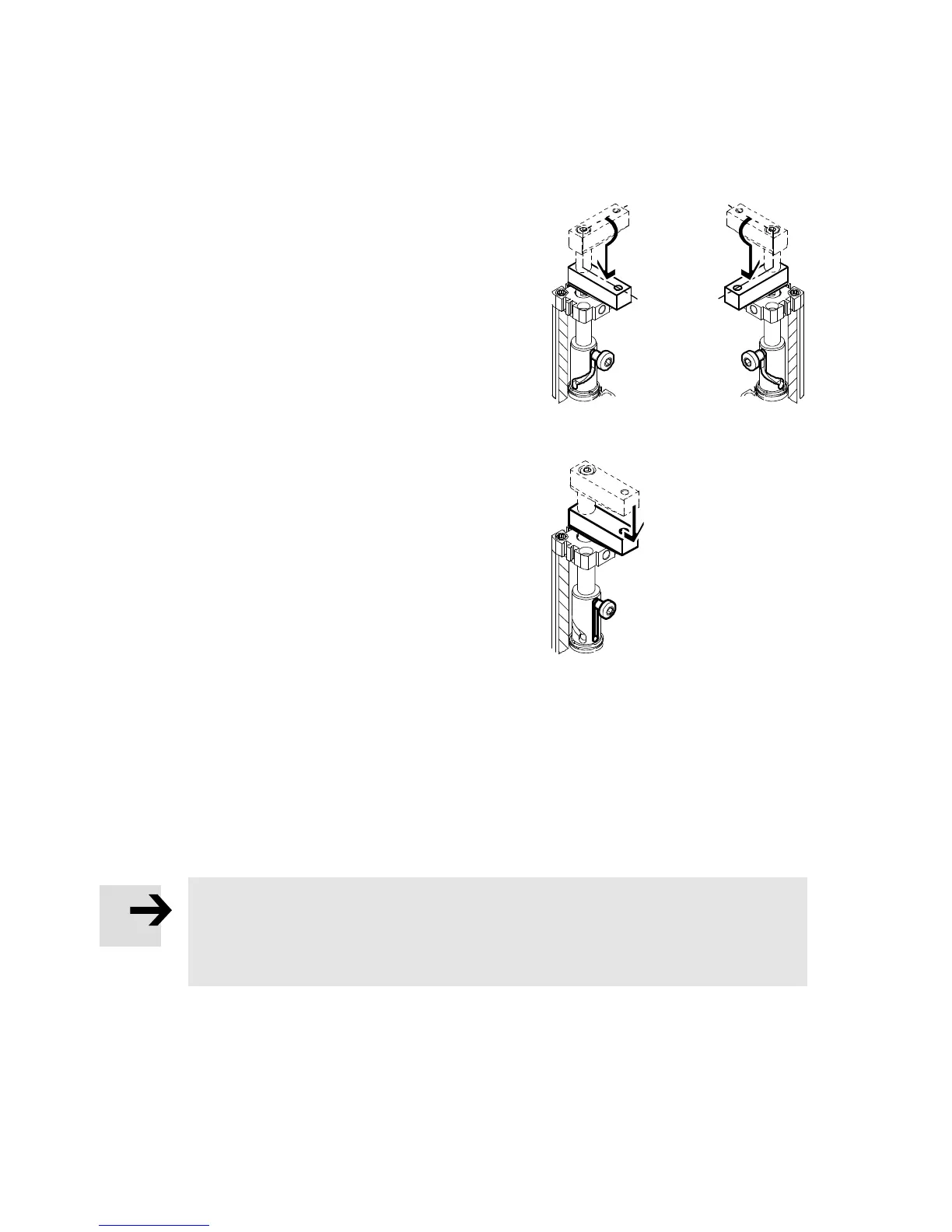

– linear movement (with CLR-40-... to

CLR-63-..., see Bild 4).

The piston rod transfers the swivel and linear

movements to the clamping finger. When the

piston rod retracts, the clamping finger

clamps material against a fixed stop. The

end positions are scanned in the sensor

grooves on the cylinder profile.

3 Application

The CLR-... has been designed for friction-locked clamping and holding of

construction parts.

Please note

Torques which affect the internal guide sleeve will damage the CLR-...

S With all assembly work make sure that the maximum torque on the guide

sleeve is not exceeded (see chapter “Mechanical installation”).

Bild 2 Bild 3

Bild 4

Loading...

Loading...