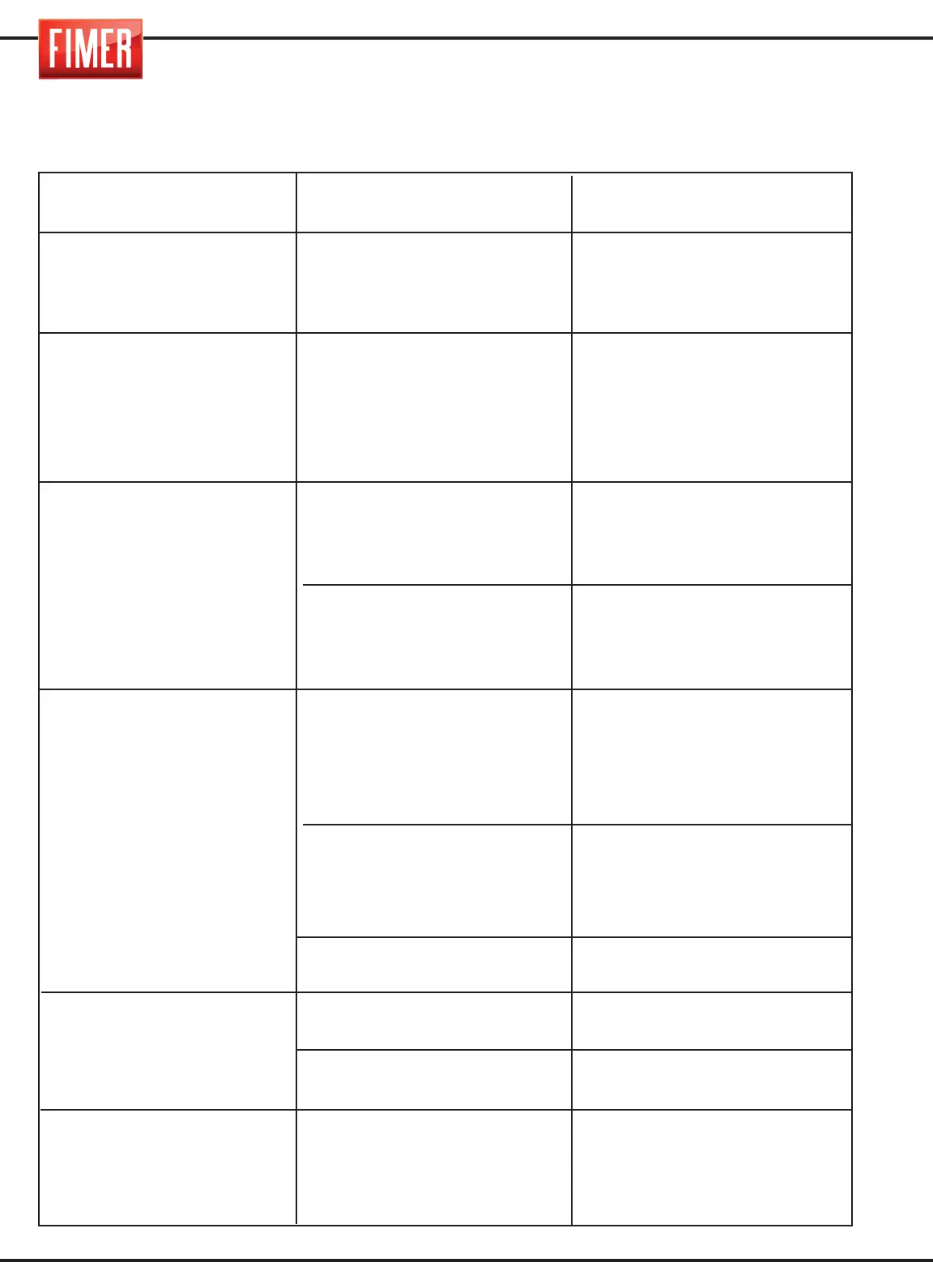

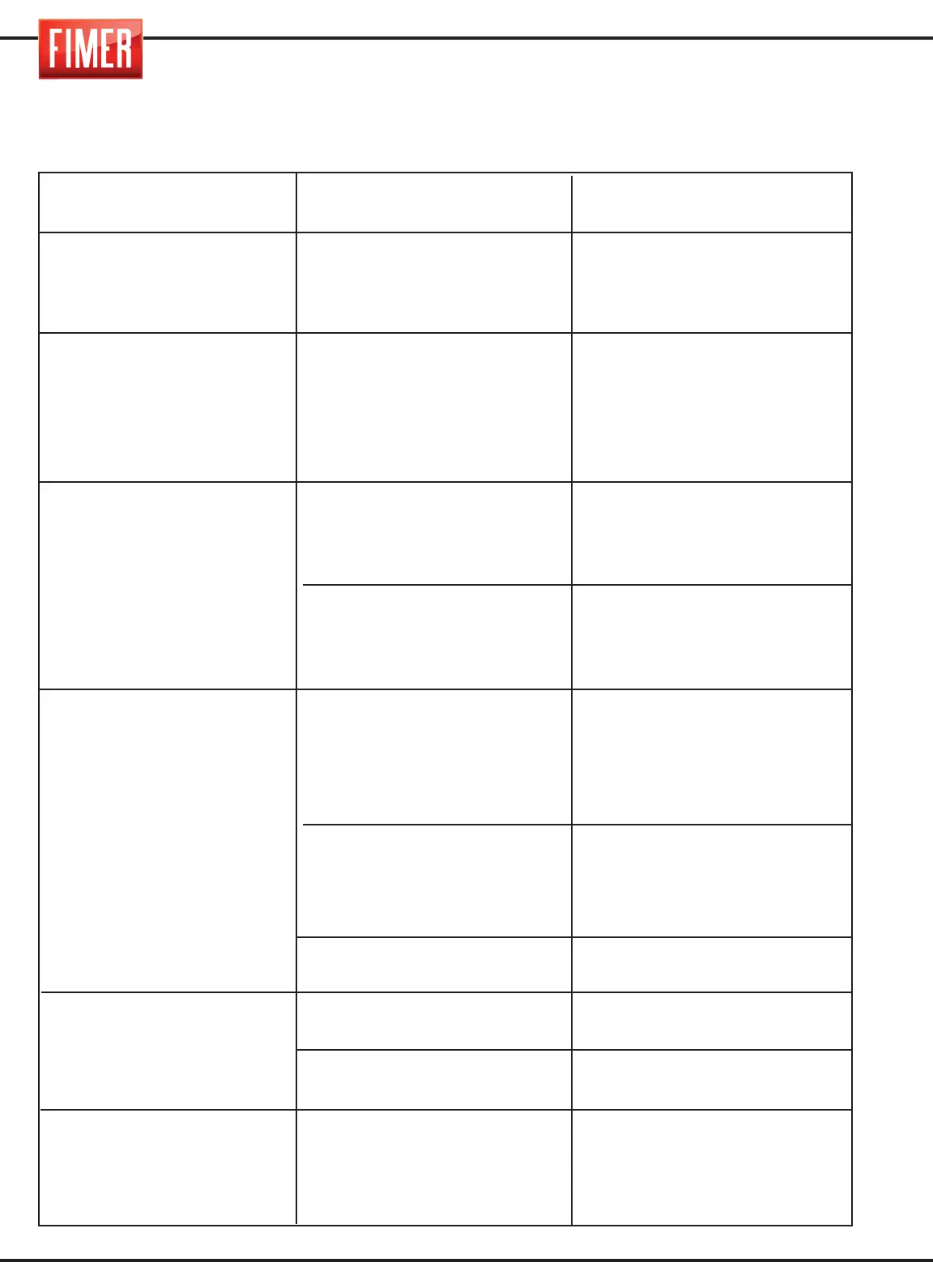

DEFECT

CAUSE

SOLUTION

The machine suddenly sto-

ps working after prolonged

use

Arc off

The machine has overheated

due to excessive use and the

thermal protection has inter-

vened.

Leave the machine to cool until

the warning message disap-

pears.

Poor contact between the earth

clamp and the workpiece.

Short circuit between the con-

tact nozzle and the gas tube.

Tighten the clamp and

check again.

Clean and replace contact

nozzle and wire-feeder tip.

Porous welding seam

Scarce fusion

Lateral incisions

Incorrect tilt angle of torch.

The distance between the tor-

ch and the workpiece must be

5-10mm; the tilt angle must be

no less than 60 degrees from

the workpiece.

Damp workpiece

Dry with a hot air pistol or

other means.

Welding arc is too long

Brusque torch movements

Shorten the arc

Clean

Rusty material

Clean

Welding speed is too high

Reduce welding speed

13. TROUBLESHOOTING

Below are a list of some of the most common problems that may arise, with the relative

solutions.

Network error

loss of phase or more phases of

Check the connection to the

power supply and check that

the fuses are intact

10

Loading...

Loading...