14

8.3 MMA WELDING

8.3.1 Description

Electric MMA (Metal Manual Arc) and

SMAW (Shielded Metal Arc Welding) are

both manual procedures exploiting the heat

generated by an electric arc that is pro-

duced when covered welding electrodes

make contact with the workpiece. It is com-

monly used due to its versatility. In fact,

welding jobs can be performed anywhere:

in a workshop, in the open, in confined

spaces or hard to reach areas. A wide

range of electrodes are available, suiting

all requirements. The arc is generated

touching the electrode to the workpiece.

The potentiometer knob (Fig. 1 –10) regu-

lates the welding current (thicker work-

pieces require higher current settings).

8.3.2 MMA Welding Features

While welding the following features come

into effect:

Arc Force: Whenever the arc tends to drop

the microprocessor automatically increases

the welding current in order to maintain and

stabilise the arc.

Hot Start: The arc is generated touching

the electrode to the workpiece. To ensure

the arc is generated efficiently, the micro-

processor increases the welding current for

app. one second, guaranteeing fast, safe

arc generation.

Antisticking: Decreases the welding cur-

rent up to minimum, when the operator

makes a mistake causing the electrode to

stick to the workpiece. The electrode can

be removed from its clamp without causing

damaging sparks.

8.3.3 MMA Welding

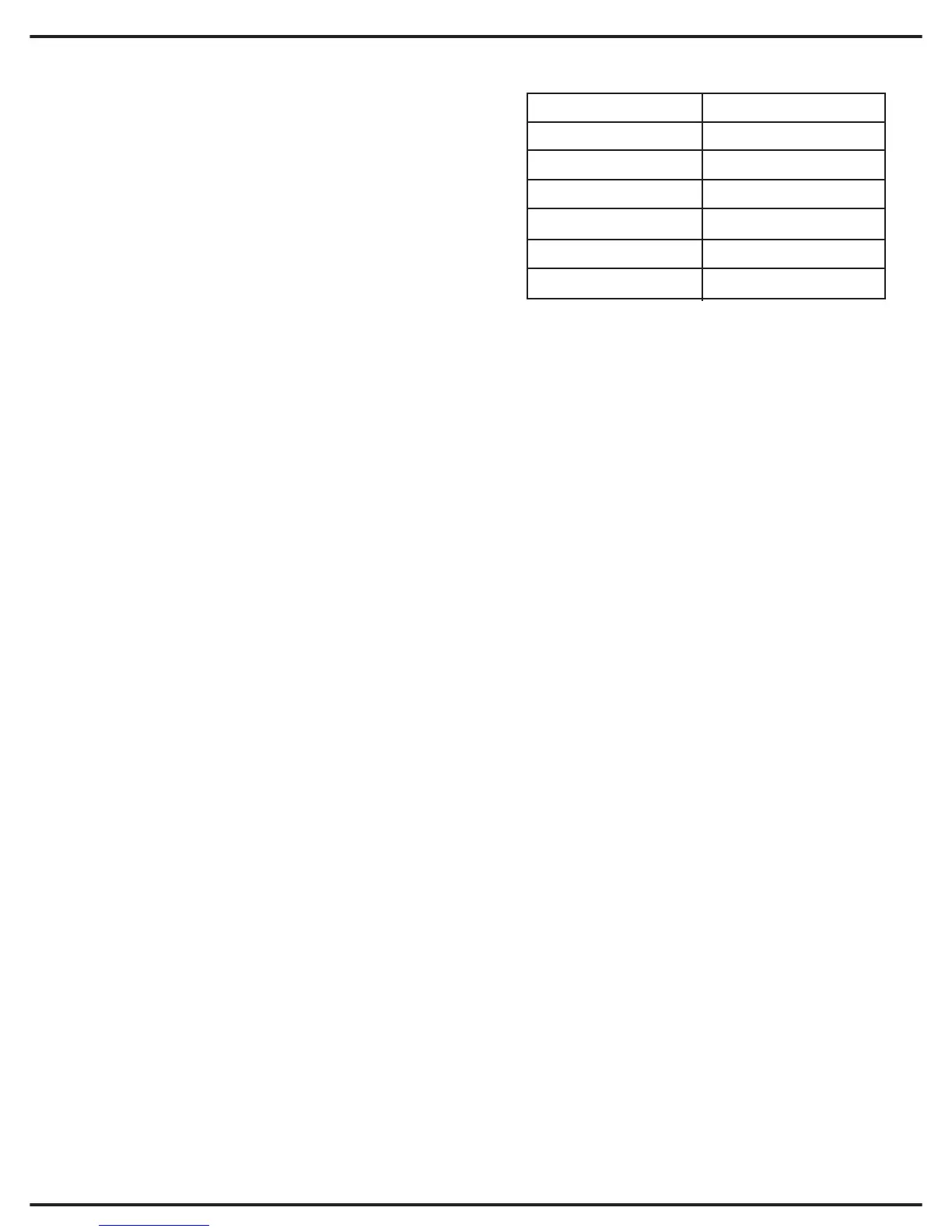

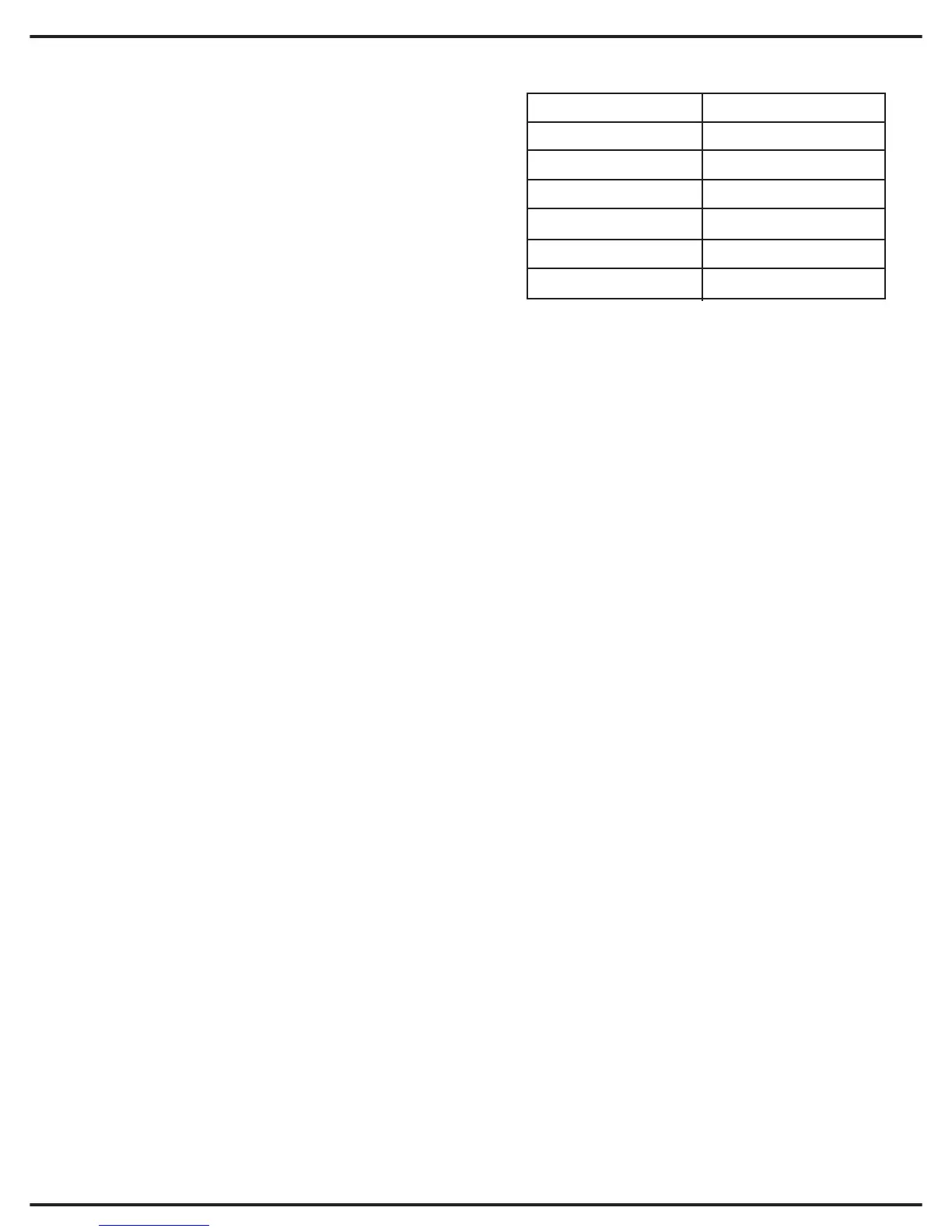

Fig 8 Welding current at the electrode

diameter.

Proceed as follows for MMA welding:

1. Using knob 10 (Fig.1) select the welding

current according to the type of electrode

and the thickness of the workpiece. The

welding current value is shown on display

panel 13. The knobs 8 and 9 (fig.1) are dis-

abled. Guidance values suitable for vari-

ous electrode diameters are provided in

Fig 9.

2. Connect the earth clamp to the work-

piece.

3. Place the electrode in the clamp.

4. During the entire welding process main-

tain a 3-4mm distance from the welding

pool that has been created. Weld using

small zigzag movements so as to be able

to regulate the size of the weld as desired.

5. Remove the electrode from the work-

piece to stop welding.

WARNING: When “Basic” electrodes are

being used, remove any residue left on the

electrode before welding. To do that, gen-

tly tap the electrode on a metallic surface.

(If residue is left on an arc cannot be gen-

erated).

Diameter (mm)

Current (A)

1.6

35-50

2.0

40-70

2.5

60-100

3.25

80-140

4.0

120-170

5.0

180-250

Loading...

Loading...