POSITIONING BOILER

Ensure that adequate clearance is available for making the water and flue connections.

As the boiler is serviced from the front, no headroom clearance is necessary but a clearance of 750mm must be available at the front of

the boiler.

No special hearth is required as the boiler is fully insulated, but the floor must be level and capable of supporting the weight of the

boiler and its water content.

Sound levels must also be a consideration.Whilst the Firebird is one of the quietest boilers on the market, some householders are

particularly sensitive and the following points should be considered:

1. Tiled surfaces in a small room will amplify noise - particularly if the wall construction is hollow.

2. If a conventional flue passes through a bedroom it is capable of transmitting noise.

3. Low level balanced flue terminals can produce exhaust noise on the outside terminal and this should be considered when siting

near adjacent property.

4. The Firebird Balanced Flue Kit has been specifically designed for Firebird’s indoor boilers. The use of third party low level flue kits is

not recommended and will affect its warranty.

5. The Siting of the boiler should take into account the disposal of condensate products.

• It is recommended that a suitable corrosion inhibitor is added to the heating system.

• Dilution of the inhibitor due to the system being constantly topped up via mains supply will invalidate

warrantee on boiler shell

• Existing systems should be treated with chemical cleaner and properly flushed before the boiler is

fitted and corrosion inhibitor added.

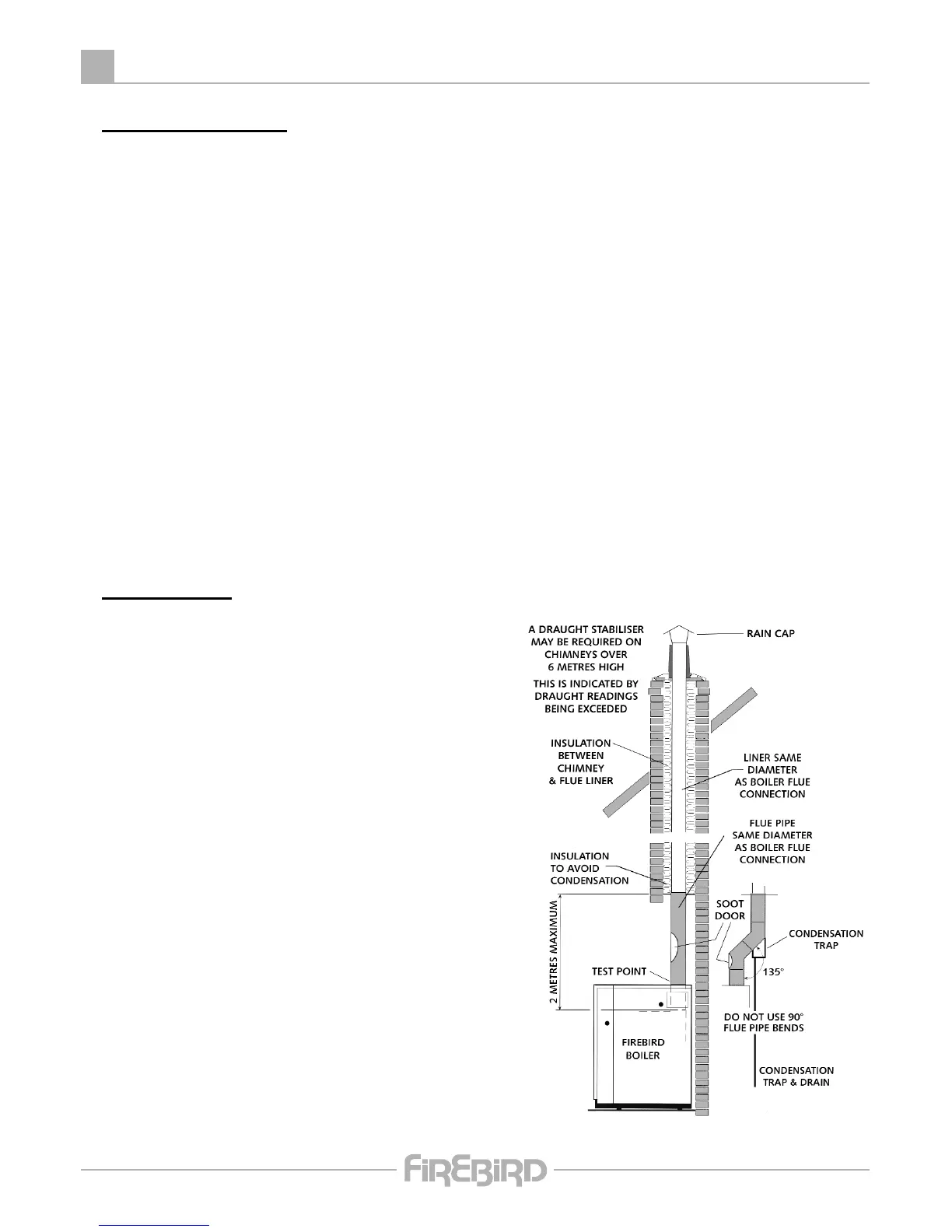

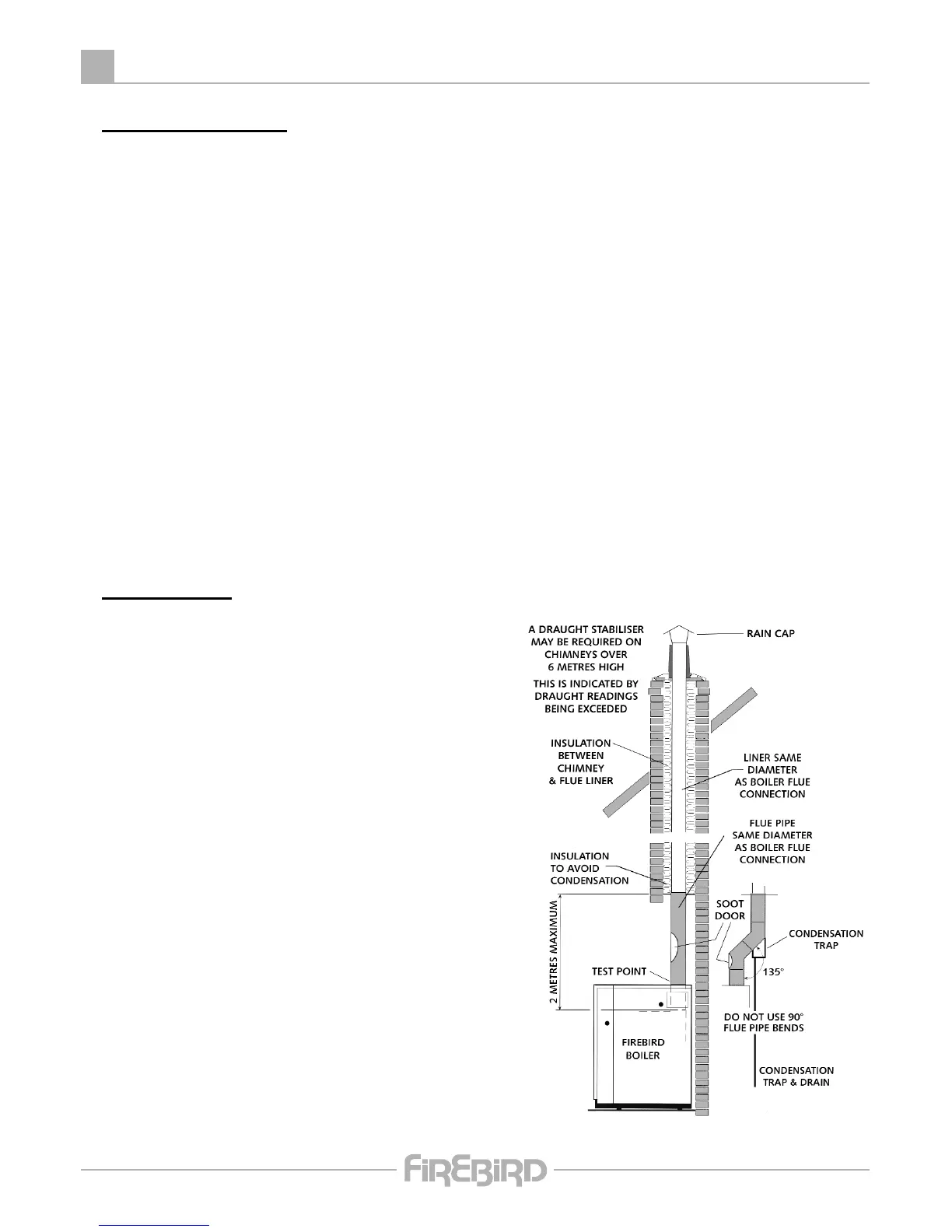

FLUE SYSTEMS

IMPORTANT

Because of the improved efficiencies of boilers under E.U. Efficiency

requirements and OFS A100 Standard, it is necessary to pay extra special

attention to flues and chimneys. The improved efficiency figures achieved

by modern oil boilers are attained by using more of the heat (higher

temperatures) heretofore allowed into flues and chimneys. This previously

wasted heat helped to keep bad and poorly operating and often

uninsulated flues and chimneys from condensing and causing problems.

Please be fully aware of this when replacing an existing boiler. An old and

poorly operating flue may need to be replaced to take full advantage of

improved efficiencies and to avoid flue gases condensing and appearing

as white water vapour (pluming) at flue (chimney) outlet.

New flues and chimneys should be properly insulated and

constructed to prevent condensation and draughting problems. Every

individual concerned with any aspect of installation should be aware of the

foregoing and should have full knowledge of and work to European,

National and Local Govt. Standards and Building and Installation

Regulations.

These manufactures instructions must not in any way be mis-interpreted

as over-riding the above or any statutory regulations. It is absolutely

essential that the boiler is properly installed so that NO FLUE GASES can

enter the building at any time. Flue pipes should be safely sealed into the

wall to prevent flue gases re-entering room or building. Refer also to page

20.

NOTE:

All brick chimney constructions must comply with current building

regulations and BS 5410: Part 1. Insulated factory made chimneys should

comply with BS 4543.

* DRAUGHT READINGS ARE SHOWN ON PAGE 9

8

INSTALLATION

17

FIREBIRD ‘S’ RANGE

CONVENTIONAL BRICK CHIMNEY WITH LINER

Loading...

Loading...