10

OIL SUPPLY

29

FIREBIRD ‘S’ RANGE

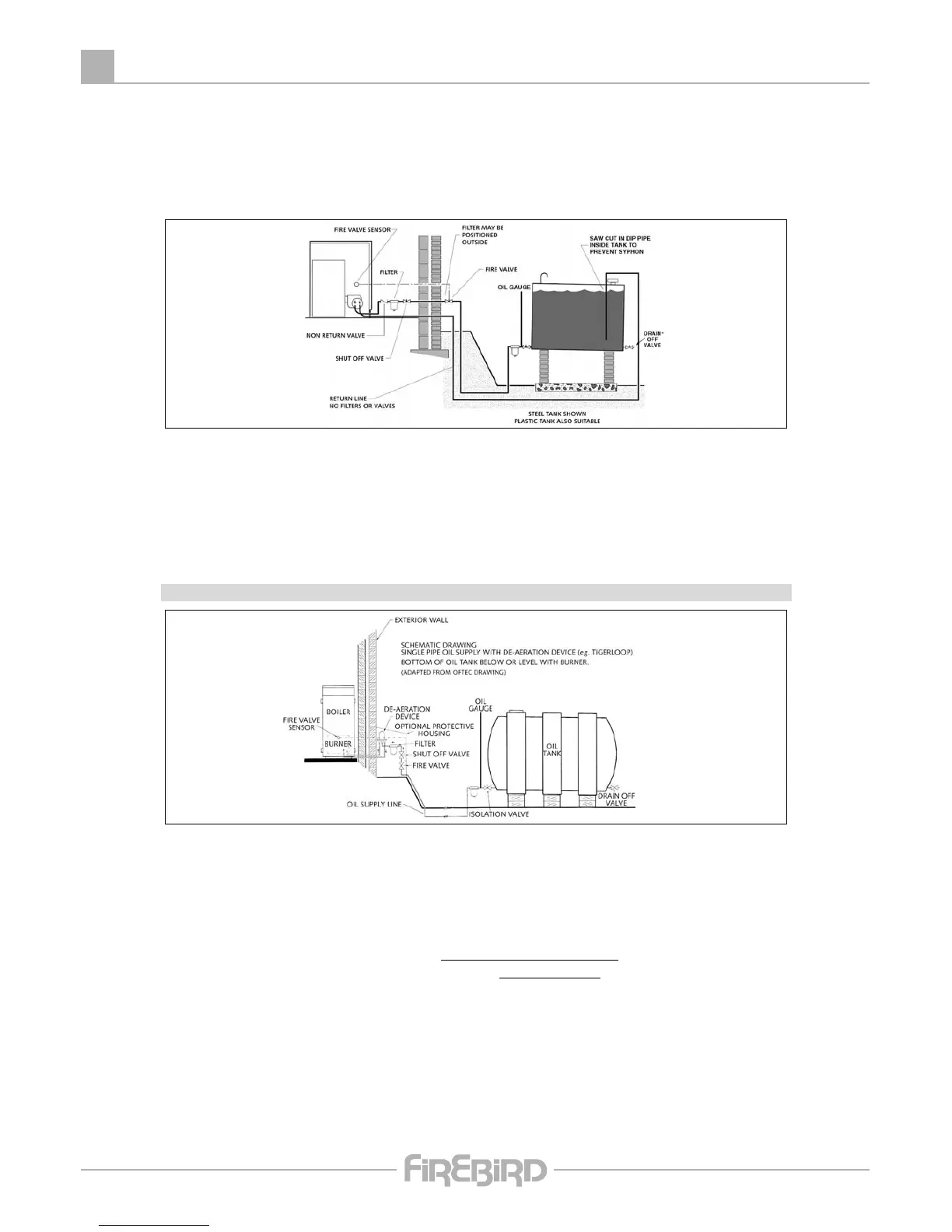

TWO PIPE SYSTEMS

Where installations have the bottom of the tank below the oil burner pump a two pipe system is required.

Ensure that valves and filters are not fitted in the return line as this must be unobstructed at all times.

The oil burner pump should be set for two pipe operation as detailed in accompanying oil burner

manufacturers manual, refer also to PAGE 15 of this manual.

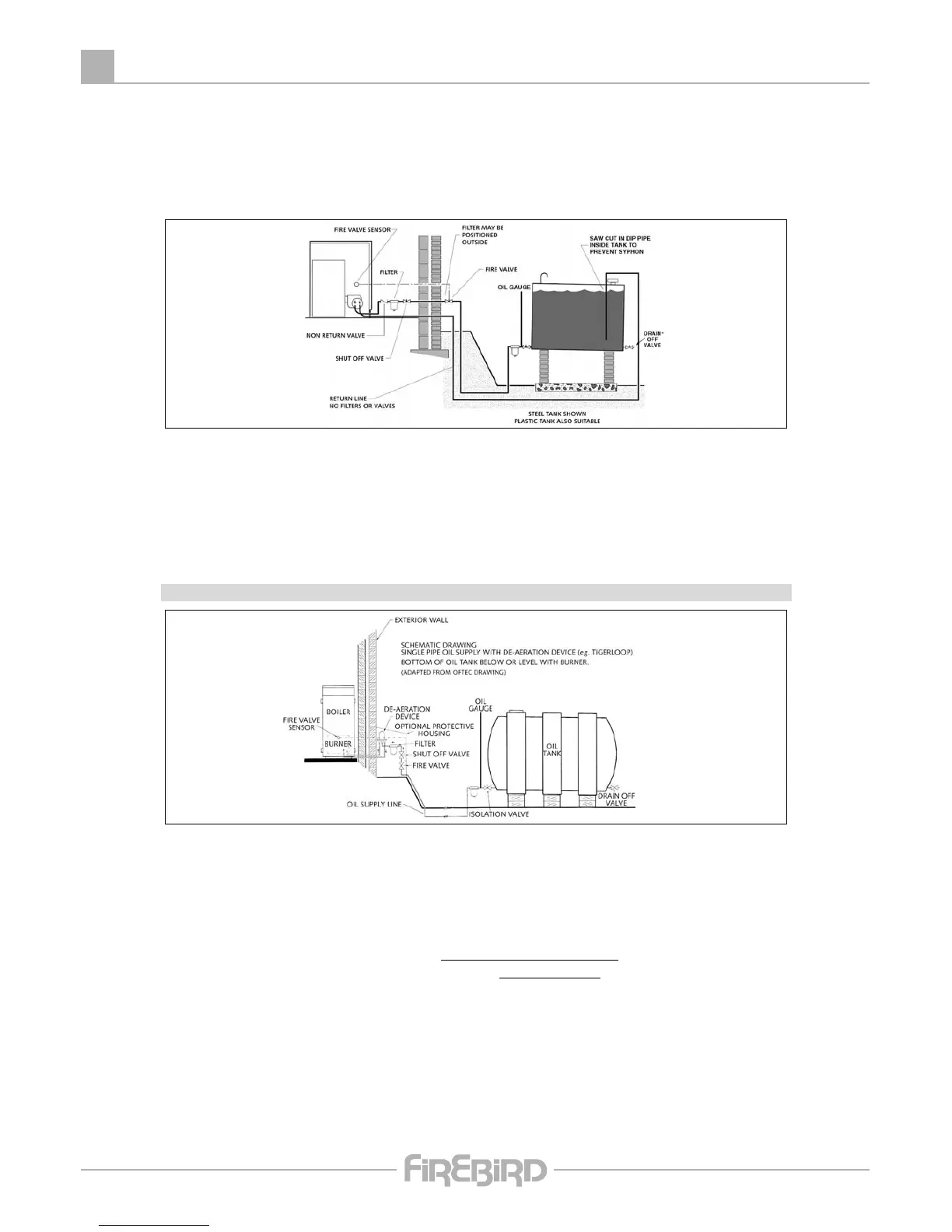

TIGERLOOP SINGLE PIPE SYSTEMS

IMPORTANT: The Tigerloop should not be fitted inside the dwelling -

See TI/139 drawing below and OFTEC manual book 3 page 2(8:1)

Where installations normally require a two pipe system but have long or impractical return line runs, a

‘Tigerloop’ De-aerator can be used which removes air from a single - pipe - lift oil feed. Higher lift heights can

be achieved than are possible with conventional two pipe systems.

The oil burner pump should be set for two pipe operation.

INDIVIDUAL TIGERLOOP INSTRUCTIONS MUST BE IMPLICITLY FOLLOWED.

☛

☛

REGULATIONS & STANDARDS

In England and Wales, installation in single family dwellings have to comply with the building Regulations Part J.This requires compliance with BS 5410 : Part

1 : 1997. All tanks either deemed to be at risk or with a capacity of more than 2,500 litres will require to be bunded.

For installation in Scotland, Building Standard Part F applies. This requires compliance with BS 5410 : Parts 1 and 2. All tanks either deemed to be at risk or

with a capacity of more than 2,500 litres will require to be bunded.

Those externally installed tanks with a capacity of less than 2,500 litres will require a bund if located not more than 50 metres from a spring or bore hole, 10

metres from controlled waters and additionally where it may constitute a hazard.

The above risks and hazards are described in OFTEC Technical Information Note TI/133.

In Northern Ireland, the Building Regulations do not currently cover the installation of oil storage tanks.

In the Republic of Ireland the requirements of BS 5410 : Parts 1 and 2 are required to be complied with be Building Regulations Part J.

FIRE VALVES

A fire valve is an essential part of the oil supply system. It should be capable of cutting off the flow of oil out-

side the building in the event of a fire starting up within the boiler. The valve should be located just outside

the building at the point where the oil supply line enters.It must be activated by a remote sensor located over

the burner, but in a position clear of any direct radiation or excessive heat.

IMPORTANT: Fire Valves should comply with OFTEC S

tandards OFS E101

Fitting of Fire Valves should comply with BS : 5410 Part 1

Loading...

Loading...