Instruction Manual

D103198X012

i2P-100 Transducer

July 2014

24

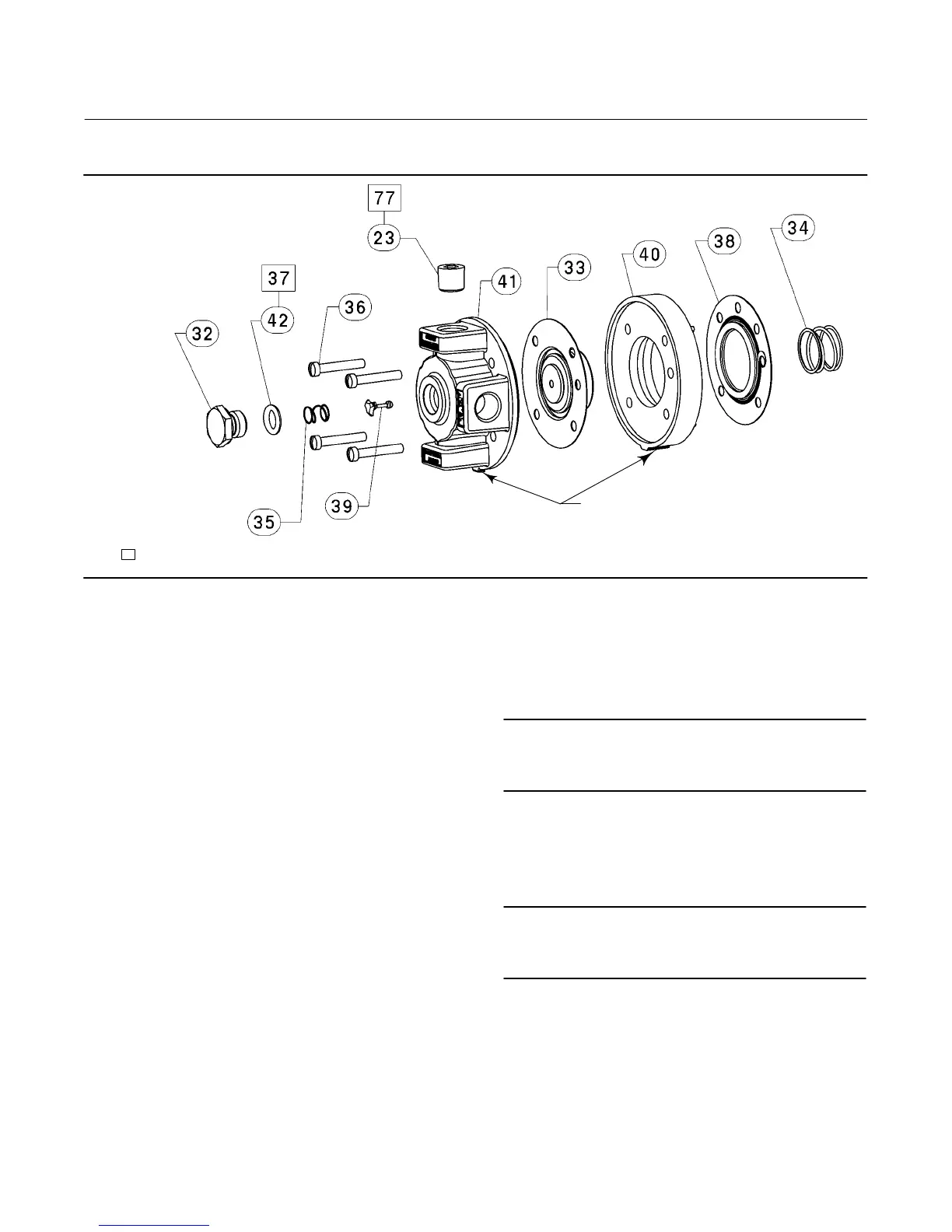

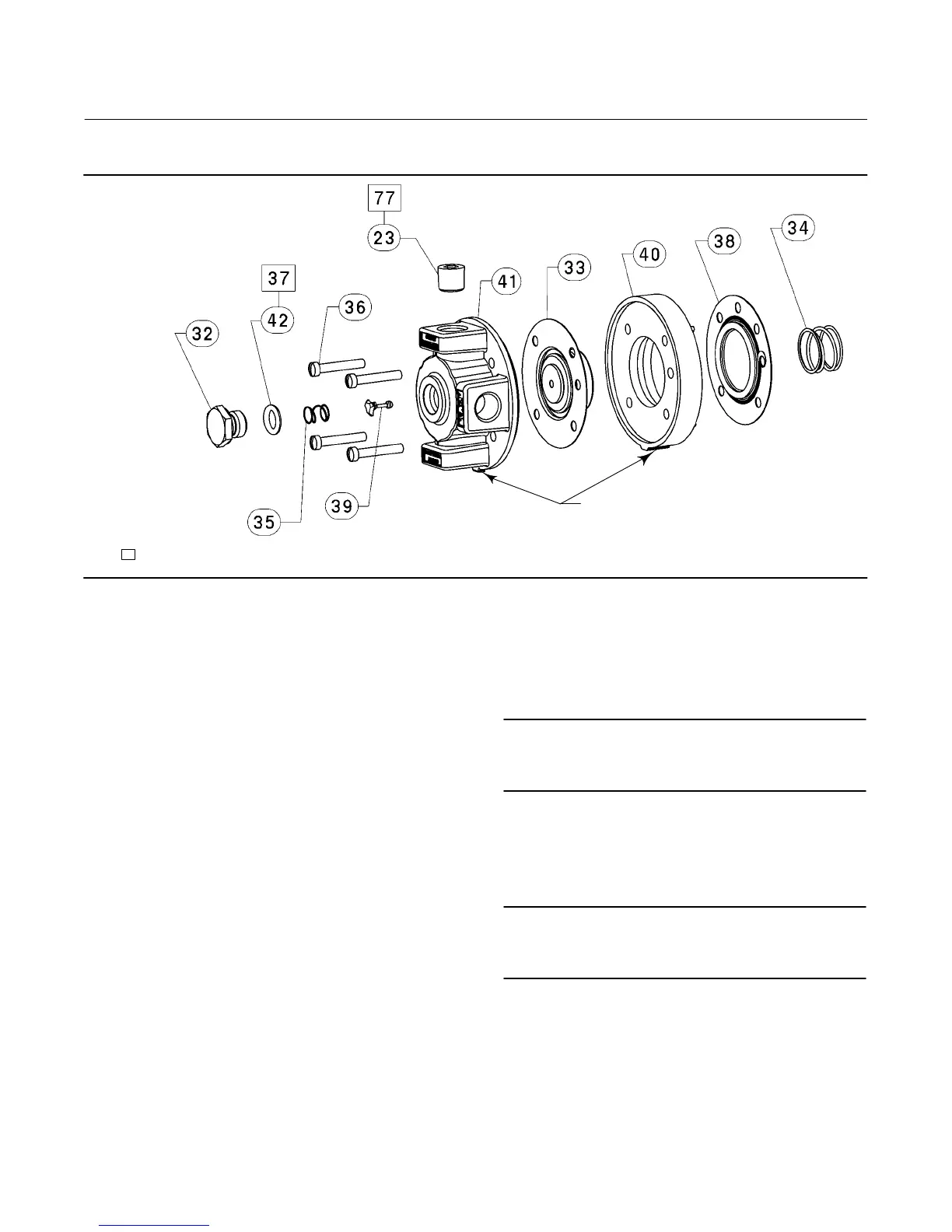

Figure 14. Fisher i2P‐100 Relay Assembly

30C2258‐B

NOTE:

APPLY LUBRICANT/SEALANT/ADHESIVE

TABS ON BODY BLOCK AND RELAY BODY MUST ALIGN

WITH TAB ON THE TRANSDUCER HOUSING ASSEMBLY

Key Description Part Number

PWB/Cup Assembly

24 PWB/Cup Assembly

97 Machine Screw (2 req'd)

98 Machine Screw

Relay Assembly (see figure 14)

41 Relay / Body Assembly

42* O‐Ring 1E5477X0062

36 Machine Screw, fill hd (4 req'd)

32 Body Plug

33 Exhaust Port Assembly

34 Spring

35 Spring

37 Lubricant, silicone sealant (not furnished with relay)

38* Upper Diaphragm 21B2362X012

39* Valve Plug 21B2370X012

40 Body Block

77 Anti‐Seize Sealant (not furnished with relay)

I/P Converter Assembly

43 I/P Converter Assembly

Gauge/Pipe Plug

23 Pipe plug, use when gauge is not specified (not shown)

Alloy steel pl

Stainless steel

23* Gauge, (not shown)

0-30 psig/0-0.2 MPa/0-2 bar 11B8579X022

0-60 psig/0-0.4 MPa/0-4 bar 11B8579X032

Key Description

Diagnostic Connections

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson Process Management sales

office.

FlowScannert diagnostic system hook‐up

Includes pipe tee, pipe nipple, pipe bushings, connector body,

and body protector. See figure 7 for part identification.

Note

If the i2P‐100 transducer is used in a valve assembly with a positioner, no

hook‐up for diagnostic testing is required for the i2P‐100. The hook‐up

for diagnostic testing should be installed at the positioner.

Side Output

For units with gauges

SST fittings

Brass fittings

For units without gauges

SST fittings

Brass fittings

*Recommended spare parts

Loading...

Loading...