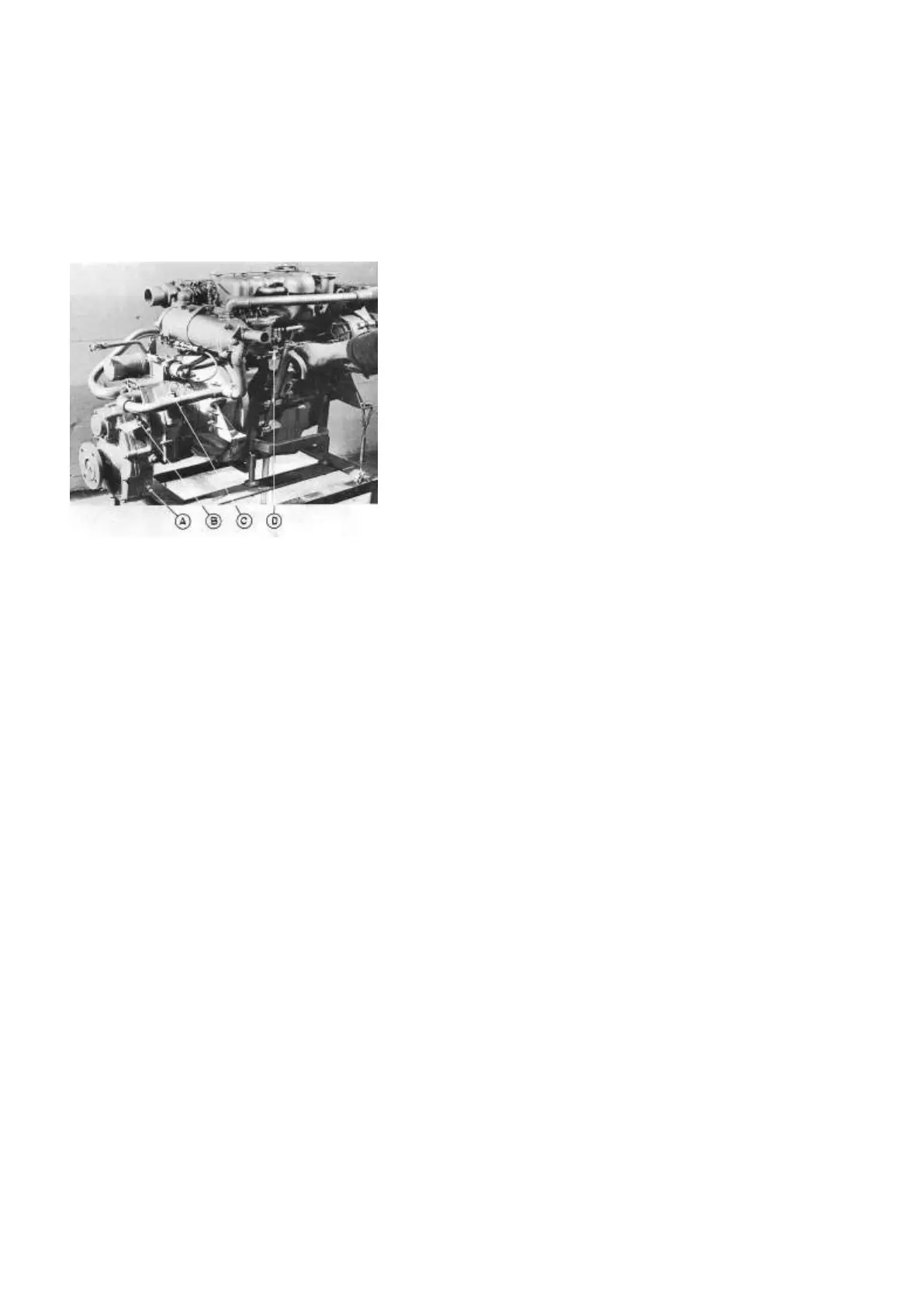

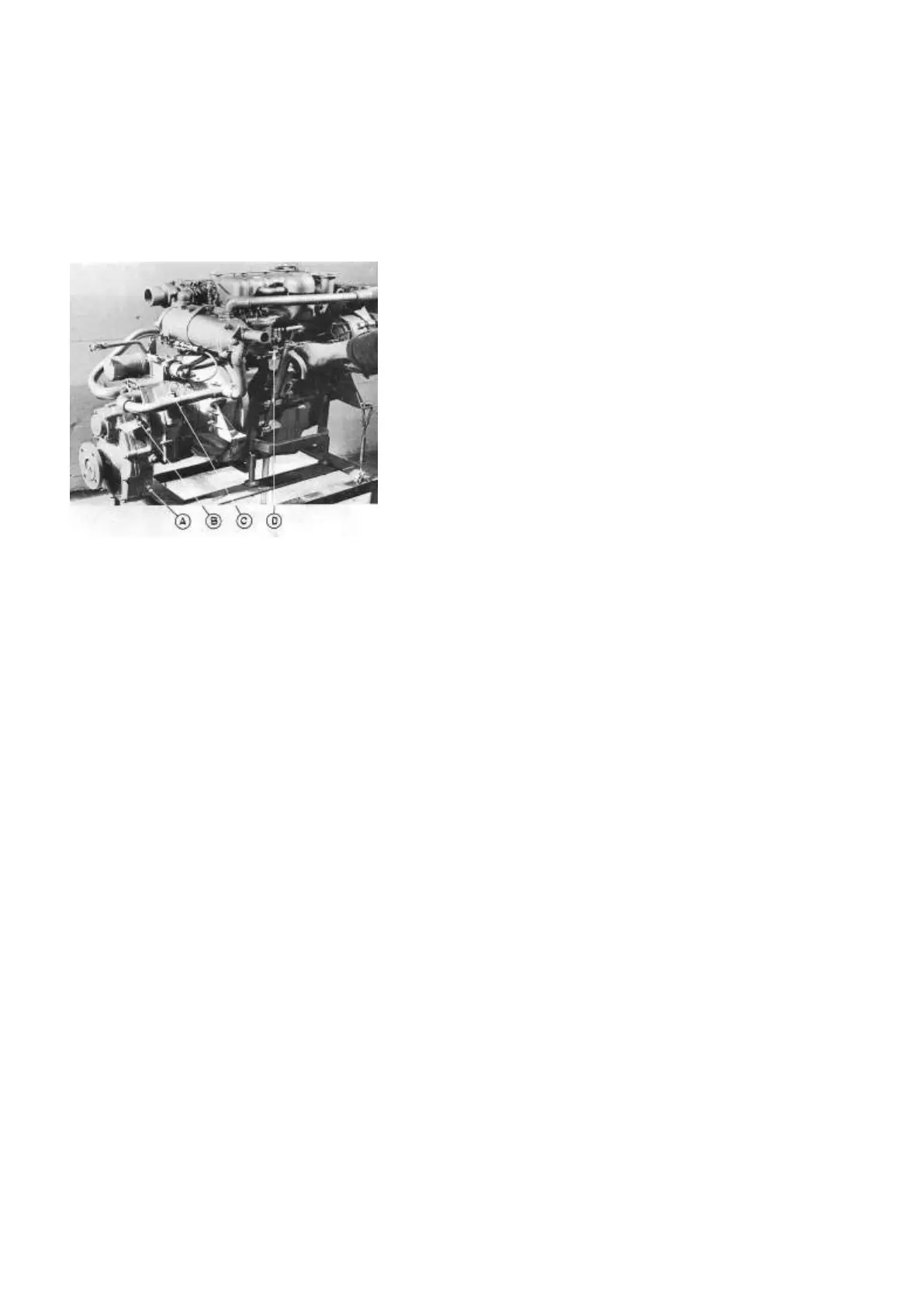

Plate 26

Engine - Starboard Side View

A) Reduction Gear Oil Level Plug

B) Reduction Gear Oil Filler Plug

C) Reverse Gear Oil Dip Stick and Filler Cap

D) Manual Fuel Feed Pump Level

e) Bleeding the fuel system

Avoid running out of fuel! If - on a diesel engine -

air is trapped in the fuel line, the engine refuses to

work. This is a consequence of the fuel injection

system. If, however, air has been enclosed in the

fuel line, either as a result of running out of fuel or

after any part of the system between the

fuel tank and the fuel injection pump has been

disconnected, the fuel system will have to be bled.

Usually the fuel system on the PERKINS 4.108 V

(and 4.107) is very easily bled (see plate 25 and 26).

Slacken the vent valve fitted on the hydraulic head

looking screw on the injection pump on the port side

of the engine (plate 25). Then operate the lever on

the fuel pump fitted on the engine’s starboard side

(plate 26) until fuel, free from air bubbles and foam,

issues from the venting screw.

(If it is not possible to move the feed pump lever, the

camshaft driving the lift pump lever may be on

maximum lift. If so, turn the engine one revolution

by using the electric starter momentarily.)

Then tighten the venting screw, and the engine

is ready for starting. Disengage the gear control

(see paragraph 3.6), push the speed control lever to

maximum speed position, and engage the starter by

turning the starting key.

If the engine does not start at this occasion, a more

comprehensive bleeding procedure has to be carried

out, as described in the “Handbook for the Perkins

Marine Diesel Engines” (delivered together with the

MANUAL) in the chapter “Bleeding the Fuel

System.”

f) Periodic attentions

The (enclosed) “Handbook for the Perkins Marine

Diesel Engines” specifies the periodic checks for the

maintenance of the engines. The handbook indicates

that, besides frequent checking of engine sump oil

level as described in paragraph 3.7 of this manual, the

coolant level and gearbox oil level should also be

checked daily if the engine is running continuously.

The filler cap for the engine coolant is visible on plate

22. To open: Push down and turn counter-clockwise.

Be careful if the cap has to be opened

when the engine is warm or hot, as the cooling system

is then under pressure. Turn the cap slowly: The level

of the coolant should be just a little below the neck of

the filler pipe.

The TMP gear box with reduction gear is divided into

two compartments: the forward one containing the

reversing gear, and the aft compartment housing the

reduction gear. The oil level on the

reversing gear box is checked by means of the dip

stick on the starboard side of the casing, while the oil

level on the reduction gear box is checked by means of

the oil level plug low down on the casing, on the

starboard side. The oil filler cap for the revers-

Loading...

Loading...