20 of 59 GH-24, GH-30, GH-45, GH-60 Rev.003

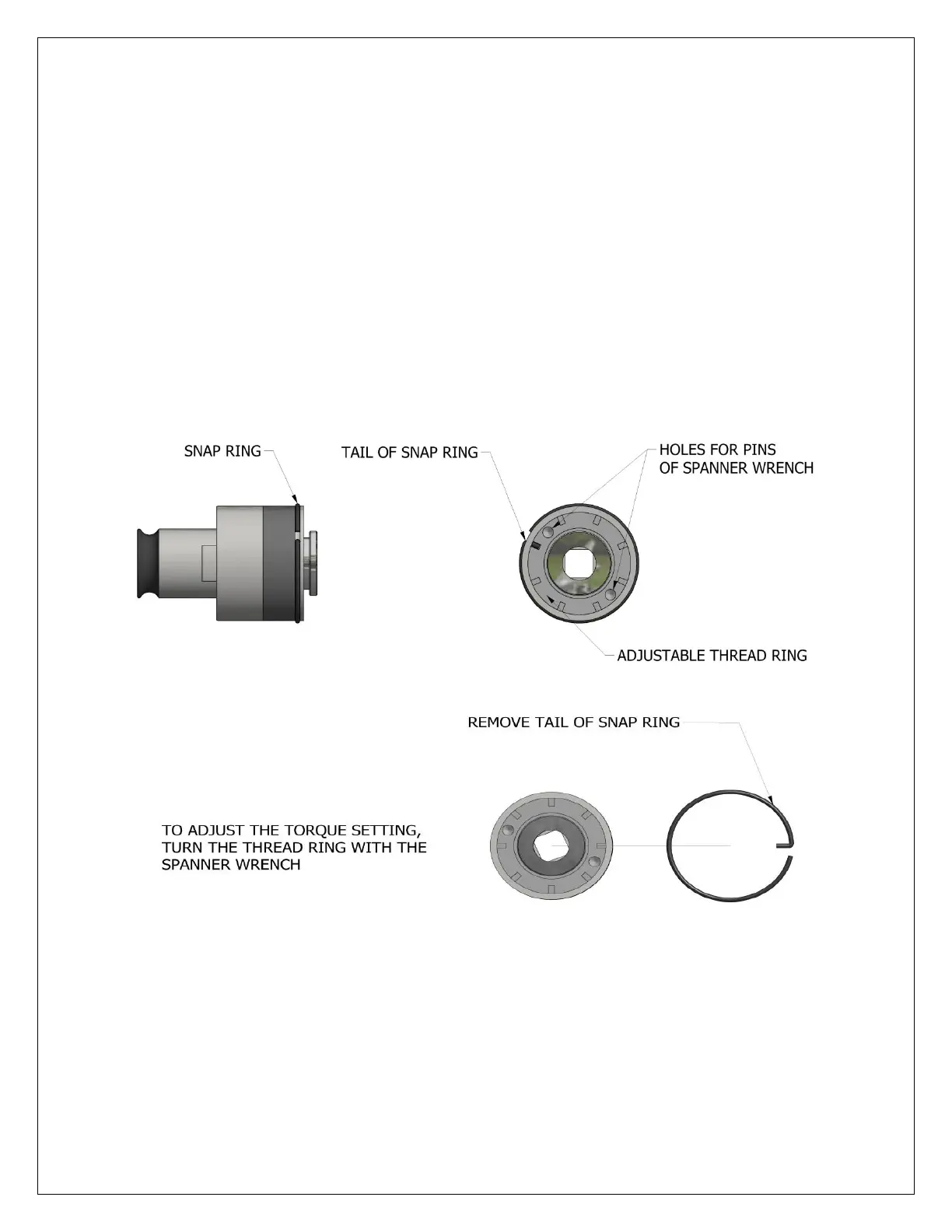

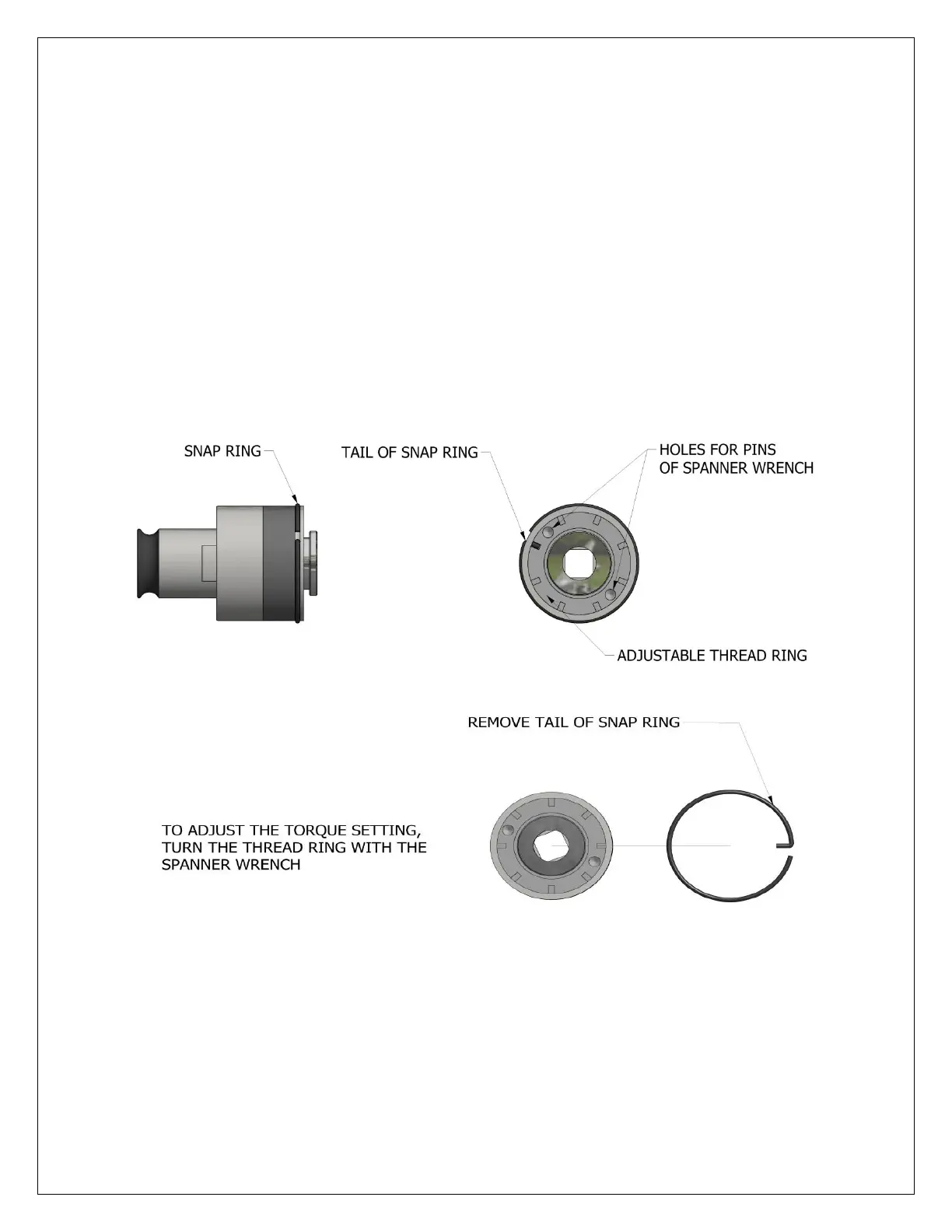

ADJUSTING TAP HOLDER TORQUE SETTING

The torque adapters are factory preset near the standard break torque limits developed for each tap size. The

break torque limit protects the tap when tapping blind or bottom holes in mild steel (approximately 229 BHN

or 25 RC). When the tap reaches the bottom of the hole, resistance will cause the torque holder’s safety clutch

to ratchet and stop the tap from turning, over-torqueing and ultimately breaking. When tapping hardened

steel (above 40 RC), stainless steel, or other tough alloys, an increase in the factory torque setting may be

required in order to drive the tap the full depth of the hole. When using the torque adapters to tap soft

materials or plastics, a decrease in the factory torque setting prevents the tap from over-torqueing after it

reaches the bottom of the hole.

Caution: Never adjust the torque setting more than one (1) notch at a time. Adverse tapping conditions and

broken taps may result!

Remove the snap ring.

Turn thread ring one notch using spanner wrench.

After turning the thread ring a full notch, reinsert the tail of the snap ring in the original hole. If a lesser

adjustment is needed, turn the adjusting thread ring half the distance between the thread ring notches.

Rotate the snap ring and insert the tail in the secondary hole position.

To increase the torque setting, turn the thread ring clockwise.

To decrease the torque setting, turn the thread ring counter-clockwise.

Loading...

Loading...