CS USER INSTRUCTIONS ENGLISH 923CSE001 - 08/03

Page 8 of 66

®

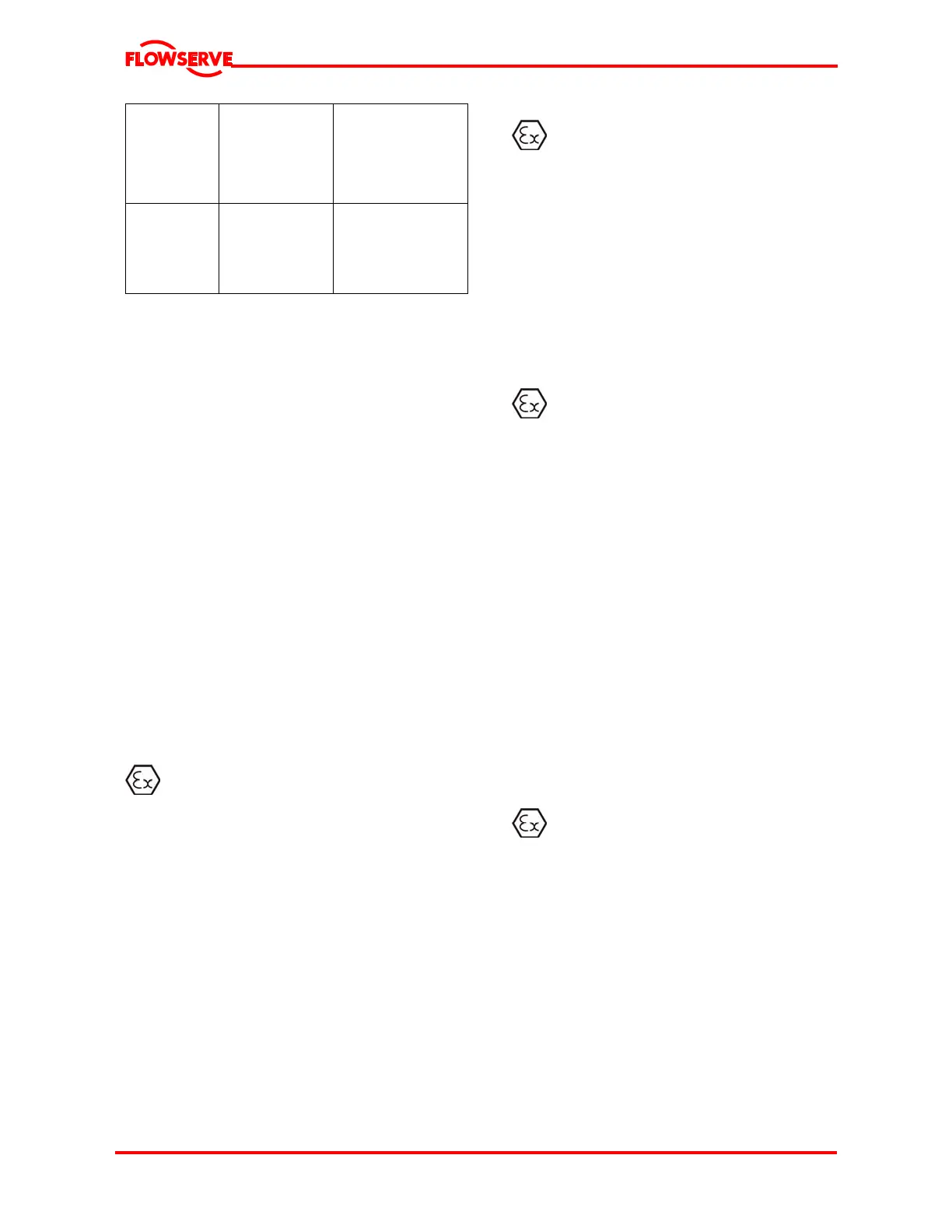

Temperature

class to

prEN 13463-

1

Maximum

surface

temperature

permitted

Temperature limit of

liquid handled (*

depending on

material and

construction variant

- check which is

lower)

T6

T5

T4

T3

T2

T1

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Consult Flowserve

Consult Flowserve

115 °C (239 °F) *

180 °C (356 °F) *

275 °C (527 °F) *

400 °C (752 °F) *

The responsibility for compliance with the

specified maximum liquid temperature is with the

plant operator.

If an explosive atmosphere exists during the

installation, do not attempt to check the direction of

rotation by starting the pump unfilled. Even a short

run time may give a high temperature resulting from

contact between rotating and stationary

components.

Where there is any risk of the pump being run against

a closed valve generating high liquid and casing

external surface temperatures it is recommended that

users fit an external surface temperature protection

device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperature monitor or a

power monitor and make routine vibration

monitoring checks.

In dirty or dusty environments, regular checks must

be made and dirt removed from areas around close

clearances, bearing housings and motors.

1.6.4.4 Preventing the build up of explosive

mixtures

ENSURE THE PUMP IS PROPERLY FILLED

AND VENTED AND DOES NOT RUN DRY

Ensure the pump and relevant suction and

discharge pipeline system is totally filled with liquid

at all times during the pump operation, so that an

explosive atmosphere is prevented. In addition it is

essential to make sure that seal chambers, auxiliary

shaft seal systems and any heating and cooling

systems are properly filled.

If the operation of the system cannot avoid this

condition the fitting of an appropriate dry run

protection device is recommended (eg liquid

detection or a power monitor).

To avoid potential hazards from fugitive emissions

of vapour or gas to atmosphere the surrounding

area must be well ventilated.

1.6.4.5 Preventing sparks

To prevent a potential hazard from

mechanical contact, the coupling guard must be

non-sparking and anti-static for Category 2.

To avoid the potential hazard from random induced

current generating a spark, the earth contact on the

baseplate must be used.

Avoid electrostatic charge: do not rub non-metallic

surfaces with a dry cloth; ensure cloth is damp.

The coupling must be selected to comply with

94/9/EC and correct alignment must be maintained.

1.6.4.6 Preventing leakage

The pump must only be used to handle liquids

for which it has been approved to have the correct

corrosion resistance.

Avoid entrapment of liquid in the pump and

associated piping due to closing of suction and

discharge valves, which could cause dangerous

excessive pressures to occur if there is heat input to

the liquid. This can occur if the pump is stationary

or running.

Draining or protecting the pump and ancillary

systems must avoid bursting of liquid containing

parts due to freezing.

Where there is the potential hazard of a loss of a

seal barrier fluid or external flush, the fluid must be

monitored.

If leakage of liquid to atmosphere can result in a

hazard, the installation of a liquid detection device

is recommended.

1.6.4.7 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED

TO AVOID POTENTIAL HAZARDS WHICH GIVE A

RISK OF EXPLOSION

The responsibility for compliance with

maintenance instructions is with the plant

operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

adversely affect the ambient conditions. Where

there is a risk from such tools or materials,

maintenance must be conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted, (see section 6).

Loading...

Loading...