CS USER INSTRUCTIONS ENGLISH 923CSE001 - 08/03

Page 7 of 66

®

CLEANNESS

Oil, grease, and liquids leaks may make slippery

surfaces and ground, assure removal of these leaks

when servicing the unit.

Machine maintenance must always begin and finish

by cleaning the ground and the external surfaces of

the machine.

TOOLS

Tooling must be suitable and have appropriated size

for the task being performed (see 6.13)

Tools handing should be in accordance with their

user instructions

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators and

persons entering the immediate area action must be

taken to avoid accidental contact. If complete

protection is not possible, the machine access must

be limited to maintenance staff only, with clear visual

warnings and indicators to those entering the

immediate area. Note: bearing housings must not be

insulated and drive motors and bearings may be

hot.

If the temperature is greater than 68 °C (175 °F)

or below 5 °C (20 °F) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

• Avoid excess temperature

• Prevent build up of explosive mixtures

• Prevent the generation of sparks

• Prevent leakages

• Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion

protection. Both electrical and non-electrical

equipment must meet the requirements of European

Directive 94/9/EC.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of

the specific atmosphere in which they are to be

installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The

party responsible for assembling the pump set shall

select the coupling, driver and any additional

equipment, with the necessary CE Certificate/

Declaration of Conformity establishing it is suitable

for the area in which it is to be installed.

The output from a variable frequency drive (VFD)

can cause additional heating affects in the motor

and so, for pumps sets with a VFD, the ATEX

Certification for the motor must state that it is

covers the situation where electrical supply is from

the VFD. This particular requirement still applies

even if the VFD is in a safe area.

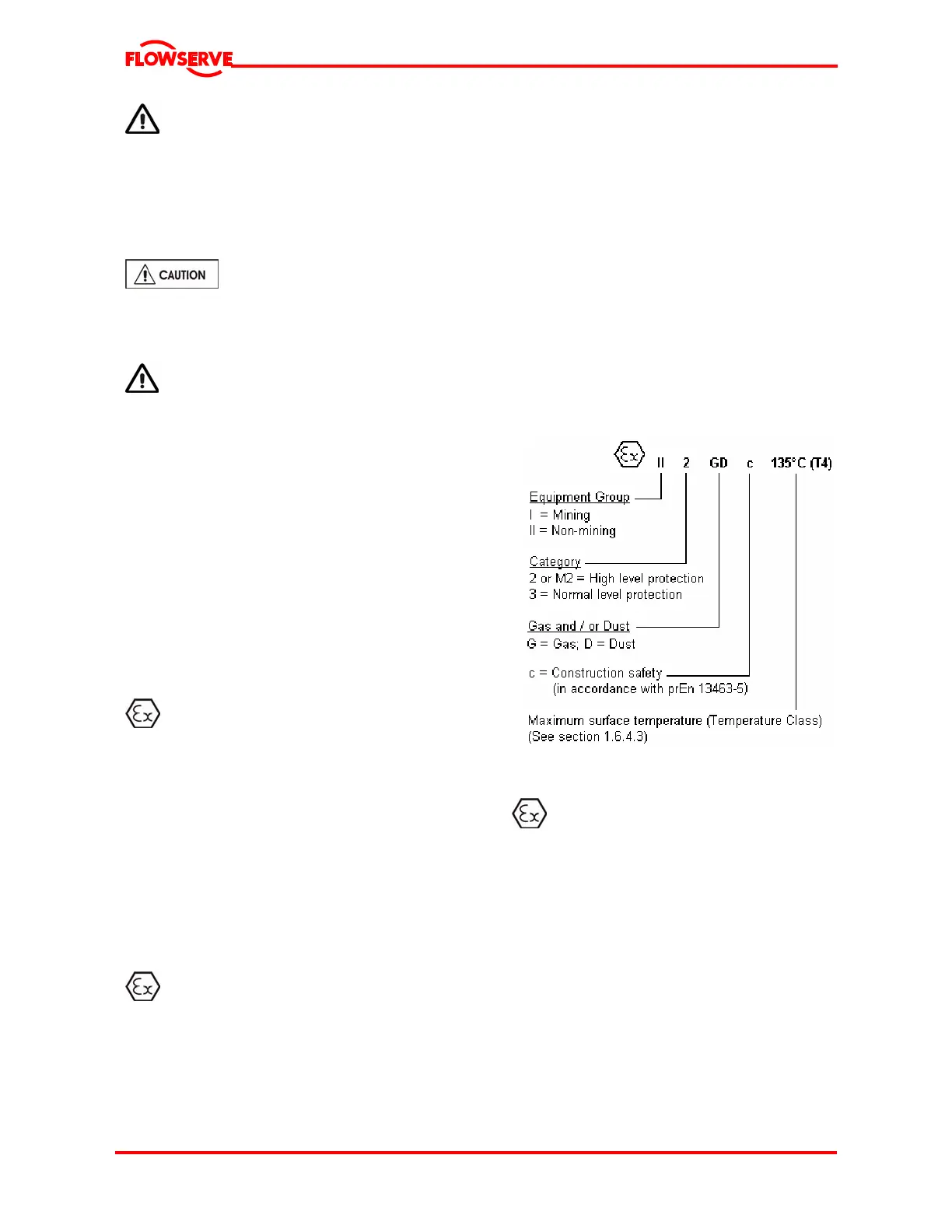

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

1.6.4.3 Avoiding excessive surface

temperatures

ENSURE THE EQUIPMENT

TEMPERATURE CLASS IS SUITABLE FOR THE

HAZARD ZONE

Pumps have a temperature class as stated in the

ATEX Ex rating on the nameplate. These are based

on a maximum ambient of 40 °C (104 °F); refer to

Flowserve for higher ambient temperatures.

The temperature of the liquid handled influences

the surface temperature on the pump. The

maximum permissible liquid temperature depends

on the temperature class and must not exceed the

values in the table that follows.

The temperature rise at the seals and bearings and

due to the minimum permitted flow rate is taken into

account in the temperatures stated.

Loading...

Loading...