DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06-12

Page 16 of 52 flowserve.com

e) Fitting an isolation valve will allow easier

maintenance.

f) Never throttle pump on suction side and never

place a valve directly on the pump inlet nozzle.

Suction strainer

4.6.2.3

In a new installation, great care should be taken to

prevent dirt, scale, welding beads and other items

from entering the pump, as it is particularly important

to protect the numerous close running fits from

abrasive matter present in new piping

The suction system should be thoroughly flushed

before installing the suction strainer and making up

suction piping to the pump.

The suction strainer should be installed between 5 to

20 pipe diameters upstream from the pump suction

flange.

The open area of the strainer should

have a minimum of a 3 to 1 ratio to the area of the

pump suction.

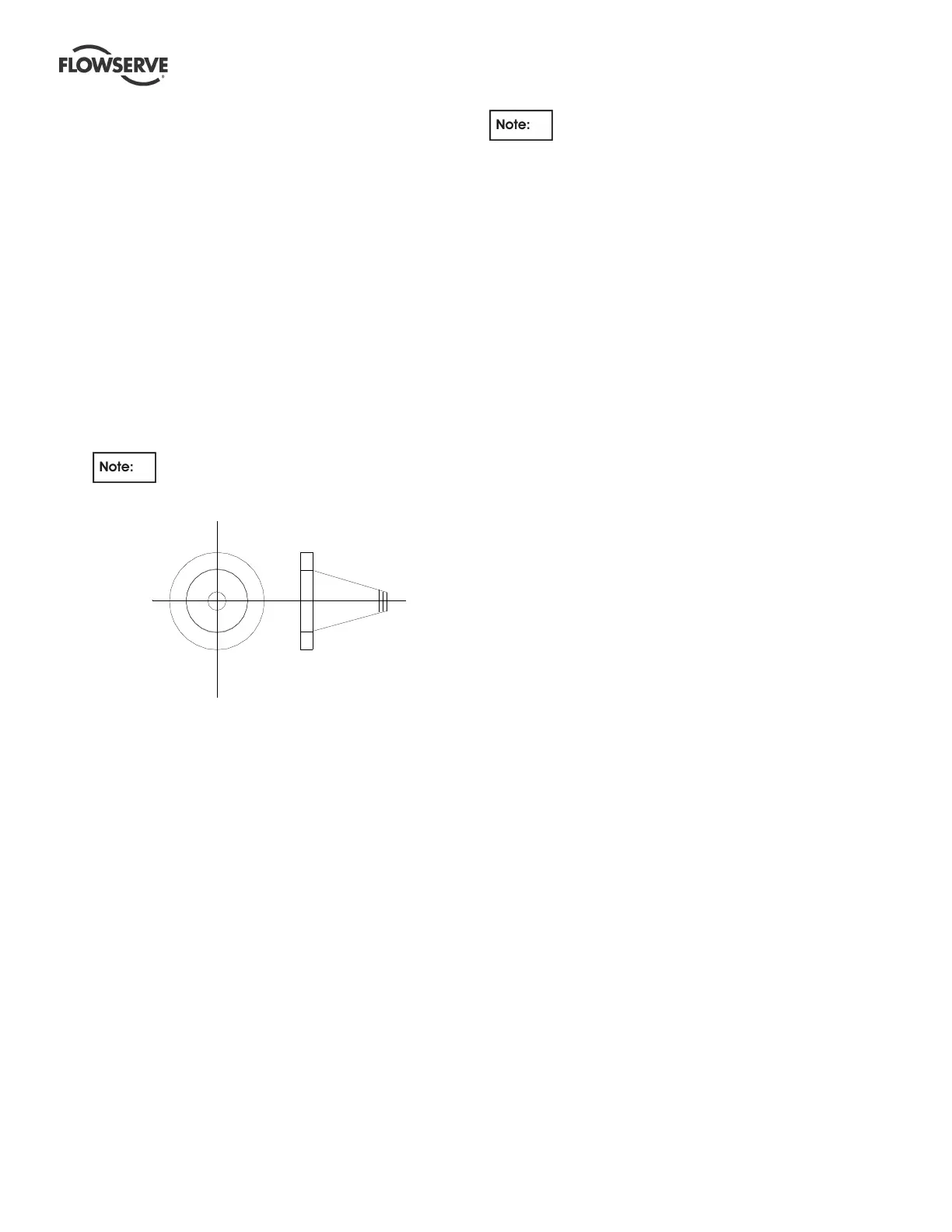

Figure 4.14

Cone Type Strainer

The FLOWSERVE recommendation for suction

strainers consists of a conical shaped steel plate. The

plate has 1.6 mm (1/16 in.) perforations and is of

sufficient size and thickness for the required flow.

See Figure above.

Other type of strainers may be used as long as they

conform to the requirements stated above.

Pressure gauges should be installed on both sides of

the screen so that the pressure drop across the

screen can be measured.

When the unit is being started, the gauges on each

side of the screen should be carefully watched. An

increase in the differential pressure between the two

gauges indicates that the screen is becoming clogged

with dirt and scale. At this point, the pump should be

shut down, and the screen cleaned and/or replaced.

A spool piece should be installed in

suction line so that the suction strainer may be

installed and removed with a pressure gauge

between the strainer and pump.

4.6.3 Discharge piping

Non self-primer casing discharge piping

4.6.3.1

a) A non-return valve should be located in the

discharge pipework to protect the pump from

excessive back pressure and hence reverse

rotation when the unit is stopped.

b) Fitting an isolation valve will allow easier

maintenance.

Self-priming casing discharge piping

4.6.3.2

a) In order to minimize friction losses and hydraulic

noise in the pipework it is good practice to choose

pipework that is one or two sizes larger than the

pump discharge. Typically main pipework velocities

should not exceed 3 m/s (9 ft/sec) on the discharge.

Pipework expanders should have a maximum angle

of divergence of 9 degrees.

b) If a non-return valve is located in the discharge

pipework then a vent/bleed pipe should be fitted

from the discharge pipe back to the sump or

source tank.

c) A regulating valve should be fitted in the discharge

pipework unless pump flow is controlled by the

delivery system design.

Loading...

Loading...