Logix™ 3800zb Digital Positioner FCD AIIOM001030_EN 02/23

flowserve.com 55

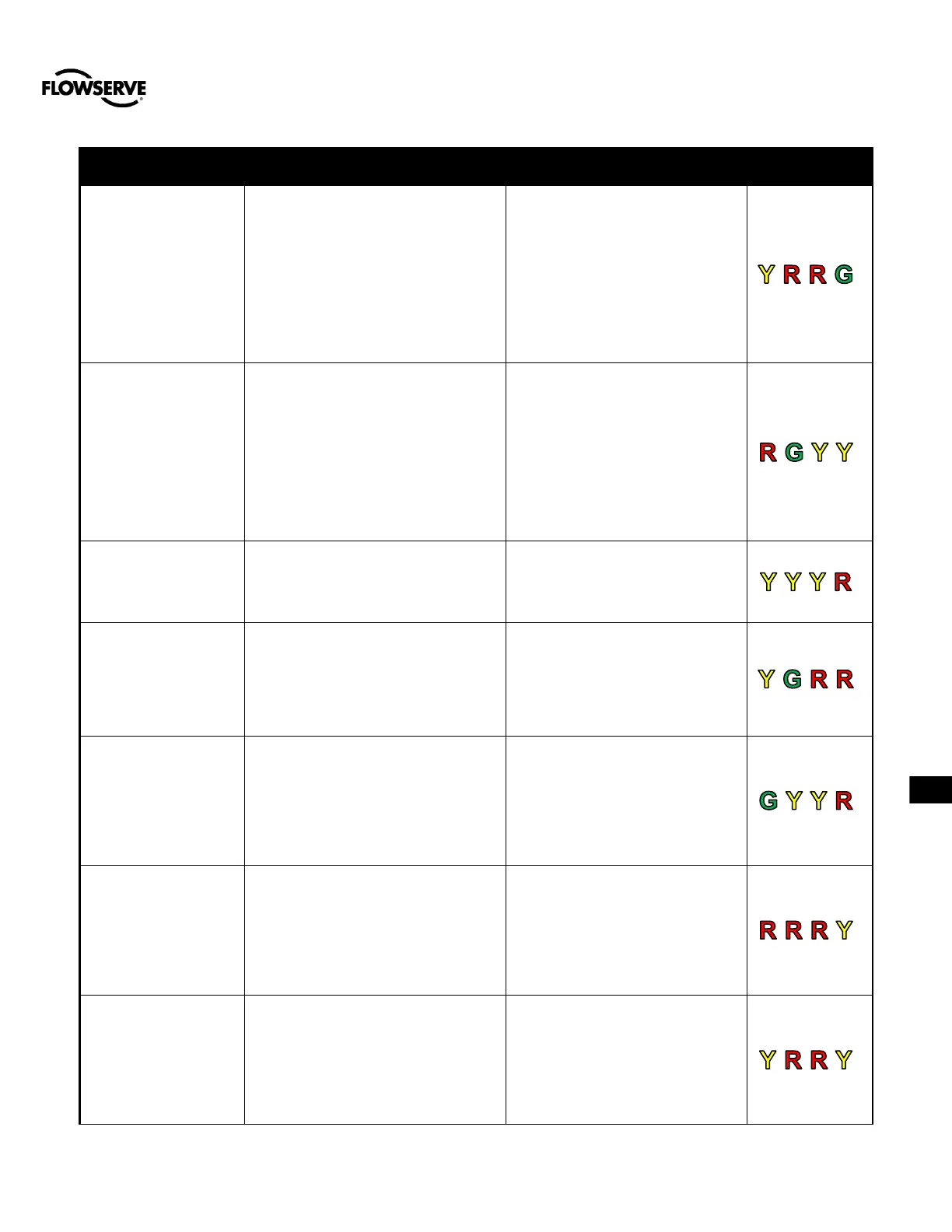

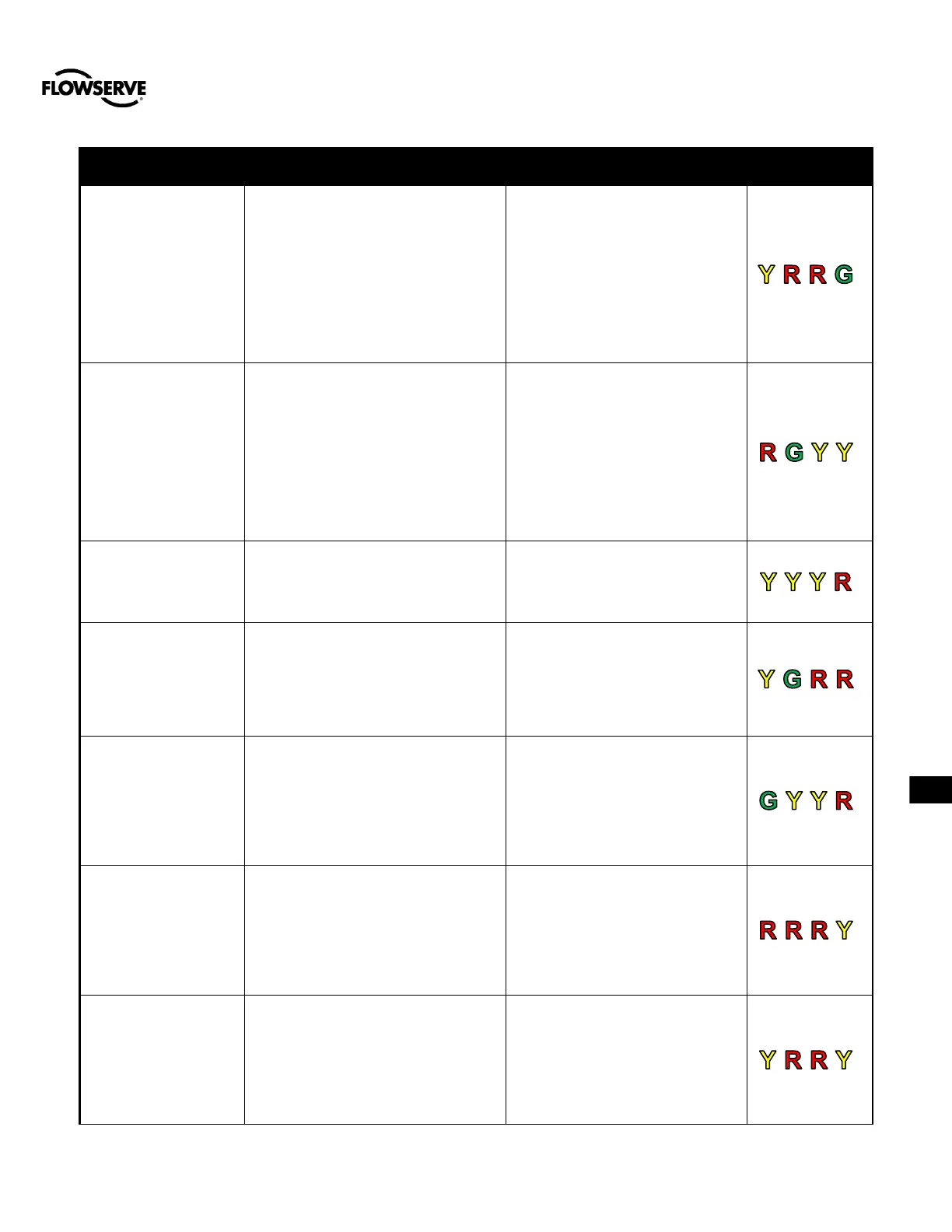

The battery for the real time clock is

low. The battery is designed for a 15+

year life with the positioner unpowered.

The battery is not required for the

positioner to control properly, but is

used only to maintain the time and date

upon loss of power. The time and date

affect the time stamps of alarms,

warnings and other events. This

warning could be caused by rapidly

power cycling the positioner.

The battery is not replaceable.

Verify or reset the time and date.

Replace the electronics assembly if

the problem persists for several

days.

During a stroke calibration, there was

no valve motion detected. Because

some valves are quite large, this

indicator can take up to 9 minutes to

detect an error.

Check linkages and air supply to

make sure the system is properly

connected. If the time out occurred

because the actuator is very large

then simply retry the QUICK-CAL

and the positioner will automatically

adjust for a larger actuator by

doubling the time allowed for

movement. This error may be

cleared by briefly pushing the

QUICK-CAL.

The CRC test of the internal data did

not pass. This may affect the function

of the positioner in various ways or not

at all. This will trigger the Memory

Error Warning.

Error may clear with time. If error

persists, cycle power and complete

a QUICK-CAL. If the error still

persists, perform a factory reset or

replace the main circuit board.

Partial Stroke Test

Failed Warning

Measured times or forces during the

last partial stroke test did not pass the

criteria set by the user. This may be an

indication of corrosion build-up on the

valve stem or in the actuator, low or

restricted supply pressure, or a sticking

positioner relay.

This warning will clear upon

completion of a successful partial

stroke test.

Partial Stroke Test

Scheduled

The schedule established by the user

shows that a partial stroke test is due.

Follow internal procedures to initiate

a partial stroke test (PST). A partial

stroke test will cause the valve to

move suddenly and the positioner

will not respond to commands while

the PST is in progress. See the

Partial Stroke Test page of the DTM

to verify PST settings.

The voltage to the piezo is too low. The

piezo may be damaged. This may

prevent the proper failure position upon

loss of signal/power. This condition

may occur briefly on an air-to-close

valve that is held for long periods of

time in the closed position, or an air-to-

open valve held in the open position.

Ensure the supply pressure is not

low. If alarm persists for more than

30 minutes, the Piezo assembly is

damaged. Replace the pilot relay.

Piezo Voltage Low

Warning

The voltage to the piezo is too low. The

piezo may be damaged. This may

prevent the proper failure position upon

loss of signal/power. This condition

may occur briefly on an air-to-close

valve that is held for long periods of

time in the closed position, or an air-to-

open valve held in the open position.

Ensure the supply pressure is not

low. If alarm persists for more than

30 minutes, the Piezo assembly is

damaged. Replace the pilot relay.

Loading...

Loading...