61

Logix

®

520MD+ and 510+ Digital Positioners FCD LGENIM0105-15-AQ – 05/16

flowserve.com

18.7 Replacing a Main Board

Removal

1. Make sure the valve is bypassed or in a safe condition.

2. Remove the outer cover.

3. Disconnect the power to the positioner.

4. Remove the inner cover. See Figure 48: Inner Cover above.

5. Disconnect the power cable to the main board.

6. Disconnect the auxiliary card cable if present. See Figure 50:

Auxiliary Card on page 60.

7. Disassemble the switch mechanism if present.

8. Remove the inner cover by removing the 6 retaining screws. See

Figure 48: Inner Cover.

9. Remove the screws from the main circuit board. See Figure 51:

Main Board Screws.

10. Gently lift the main board rotating the bottom up while keeping

the top in place.

11. Disconnect the pressure sensor board cable, the hall sensor

cable, the piezo cable and the feedback cable. (Use a small flat

screwdriver to pry the locking features and carefully separate the

connector from the main board. Be careful not to pull the cable,

as this may cause damage to the cable.) See Figure 52.

Installation

1. Place the main board on the positioner base with the 4-20 mA

input on the same side as the electronic access ports.

2. Lift the main board rotating the bottom (configuration switches)

upwards while keeping the top in place.

3. Connect the pressure sensor board cable, the hall sensor cable, and

the feedback cable. Ensure the connector’s locking features engage.

4. Place the main board on the positioner base, ensuring the cables

are clear of the feedback gears. Insert the two retaining screws.

5. Replace the inner cover by inserting the 6 retaining screws.

6. Calibrate.

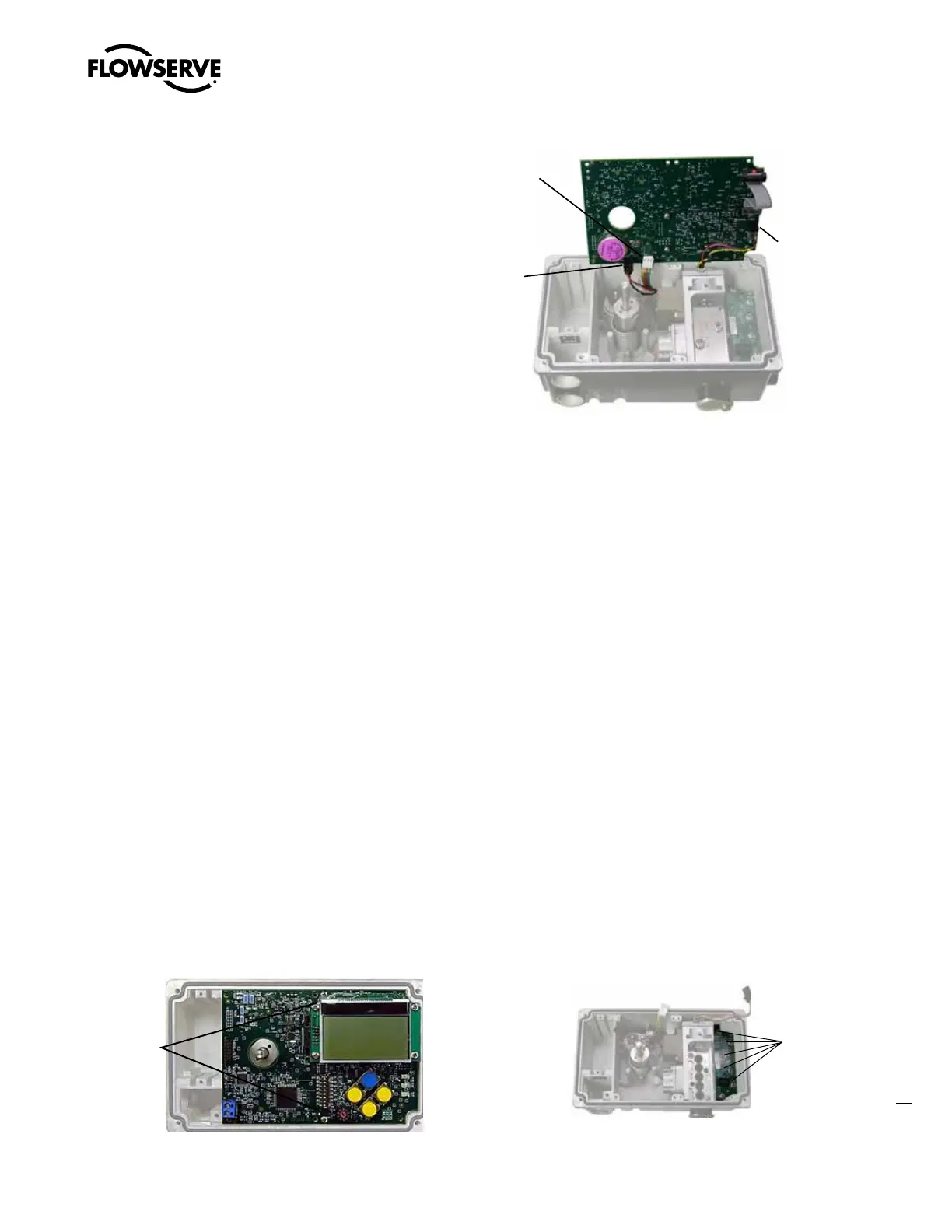

Figure 51: Main Board Screws

Hall

Sensor

Connector

Piezo

Connector

Feedback

Pot

Connector

Figure 52: Main Board Connectors

18.8 Replacing the Pressure Sensor Board

Removal

1. Remove the main board. See procedure above. (Disconnecting

the hall sensor and feedback cables is not required.)

2. Unscrew the 6 screws holding the pressure sensor board in

place. See Figure 53.

3. Remove the pressure sensor board.

Installation

1. Place the pressure sensor O-rings in the three holes.

2. Cover the O-rings with the pressure sensor board.

3. Insert the 6 screws. Tighten until the pressure sensor board

makes firm contact with the base.

Calibration

1. Initiate a Pressure or Triple Calibration from the LCD or DTM.

2. To calibrate the supply pressure sensor 0 value, disconnect the

supply air. Go to Edit Variables. Write the value from variable 74

(PS ADC Count) to variable 71. (PS ADC Count at 0 psi). Recon-

nect the supply air.

3. To keep the calibration values even after a Factory Reset, write a

1 to Variable 104.

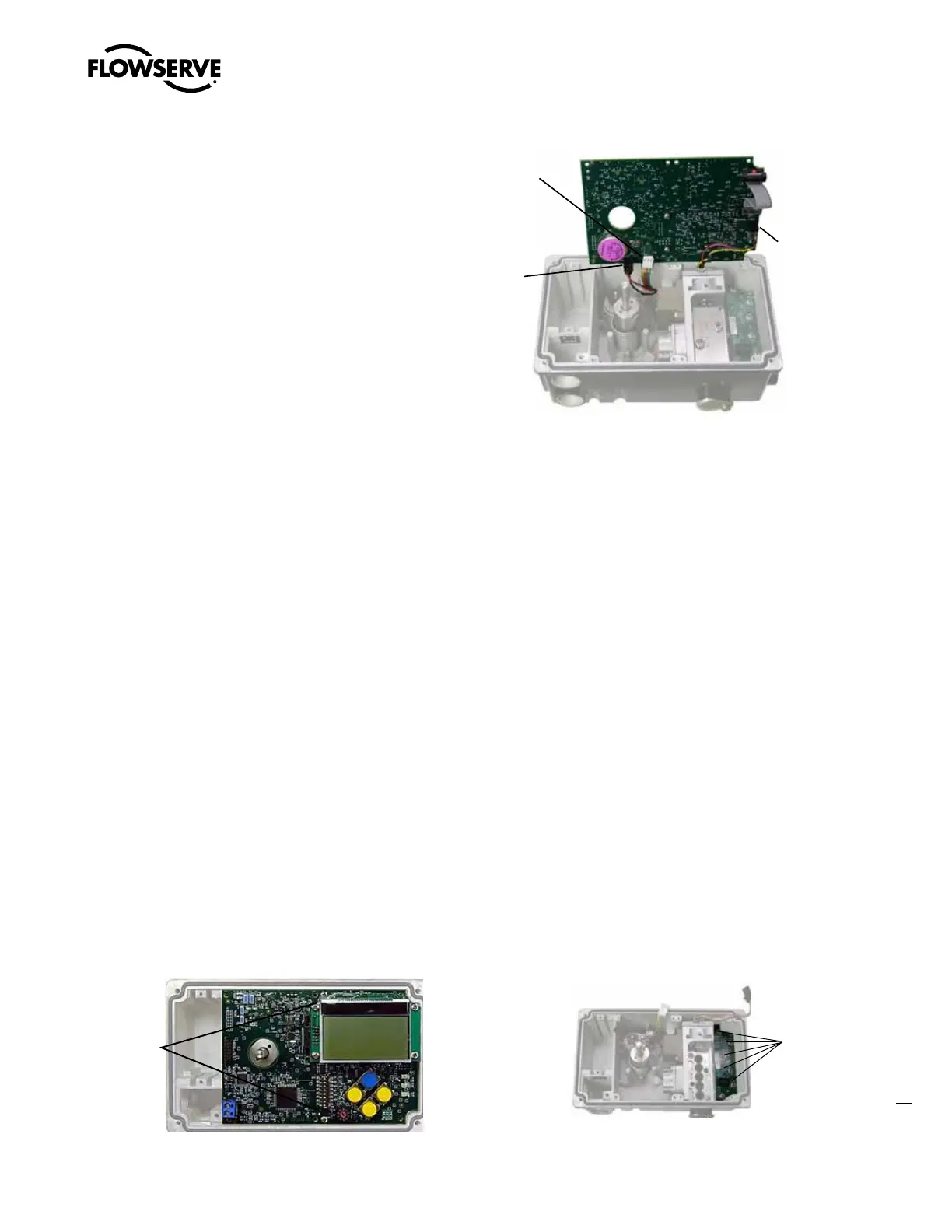

Figure 53: Pressure Sensor Board

Main

Board

Screws

Pressure

Sensor

Screws

Loading...

Loading...