EP5 Electro Pneumatic Digital Positioner FCD PMENIM0006-00-A5 12/18

13

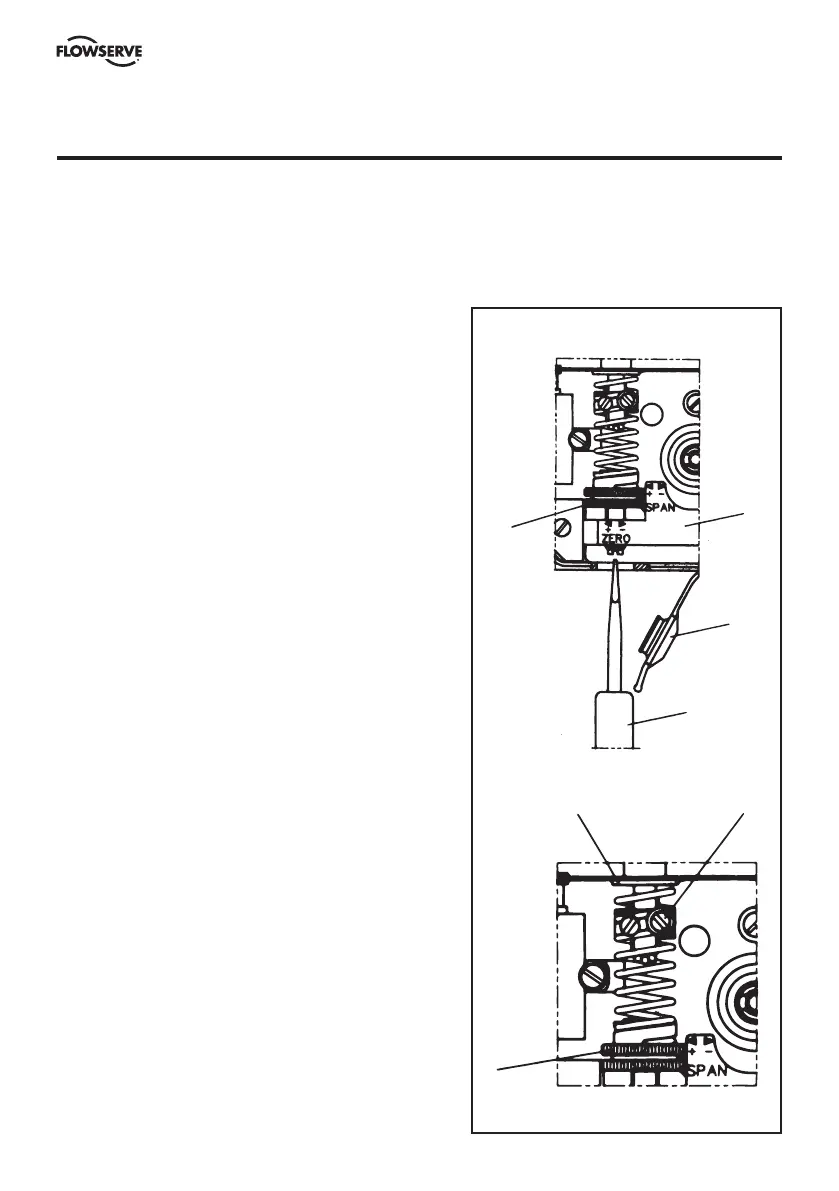

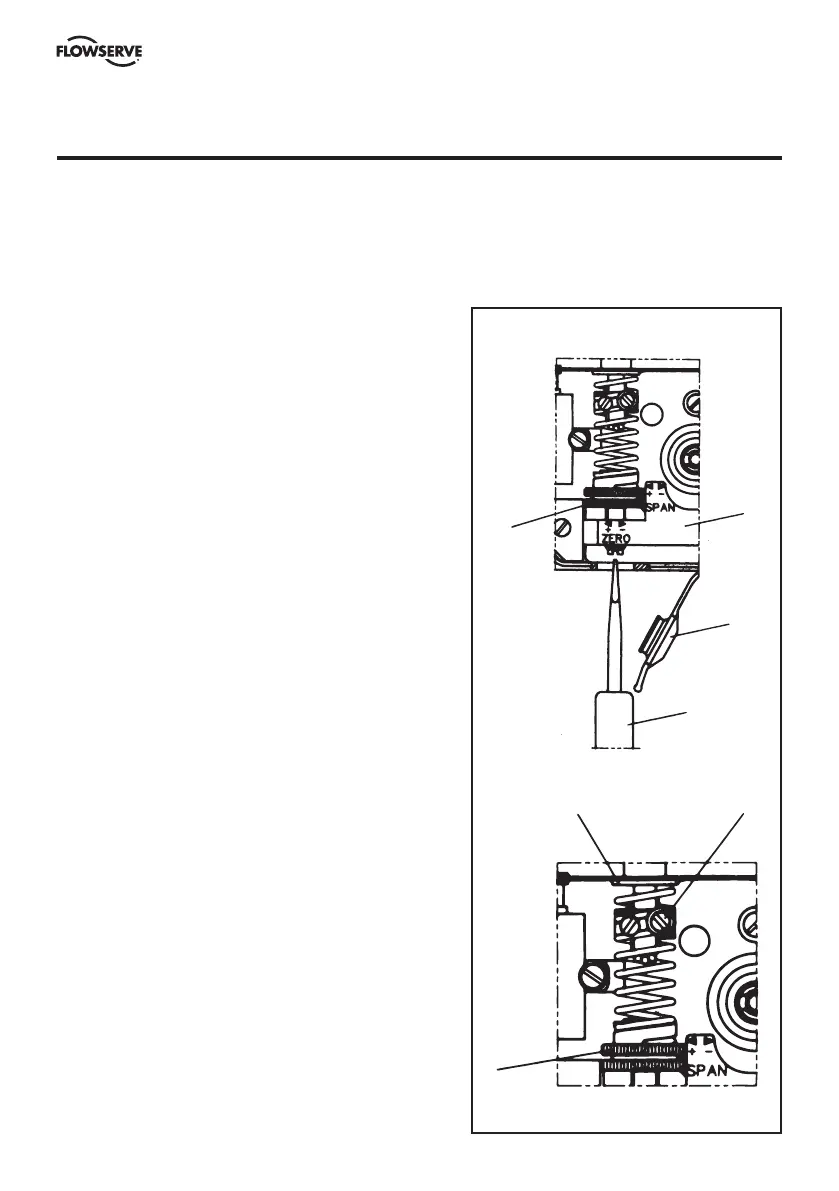

7. Calibration

P4/P5/EP5 is when shipped from PMV pre-calibrated for 90 ±0,5 deg rotation, (can also be 30, 45

or 60 deg, see installed cam). For most applications the valve closed position is more critical than

valve open position, most attention should be paid at valve closed position. Always start calibration

procedure by applying 0 % input signal, then adjusting zero. P4/P5/EP5 is calibrated by turning

thumb wheels 1 & 4.

Arrows on arm 5 indicate turning direction

of thumb wheels.

< “+“ = Increase zero/span

> “–“ = Decrease zero/span

Calibration procedure

Check cam seating, section 6 before starting calibration

procedure.

1. Apply 0 % input signal (0% = 20 kPa/3 psi or 4 mA)

2. Wait for steady state.

3. Adjust zero by turning the silver (lower) thumb wheel

4 with finger or with screw- driver 7 from the outside.

4. Apply 100% input signal (100% = 100 kPa/ 15 psi or

20 mA)

5. Wait for steady state then memorize result.

6. Apply 0% input signal.

7. Adjust span if necessary. This is done by first loosing

screw 2, then turning the yellow (upper) thumb wheel

1 “+“ or “–“ and finally tighten screw 2. Spring top

must not be in contact with spring guide 3.

8. Check zero and adjust if needed.

9. Repeat steps 2 to 8 until desired calibration is

achieved.

3

1

2

4

5

6

7

For calibration of APEX 7000 please see

appendix A Calibration Procedure APEX 7000

Loading...

Loading...