Common Problems

B

Use Part

B-5

1. What to do after automatic leveling?

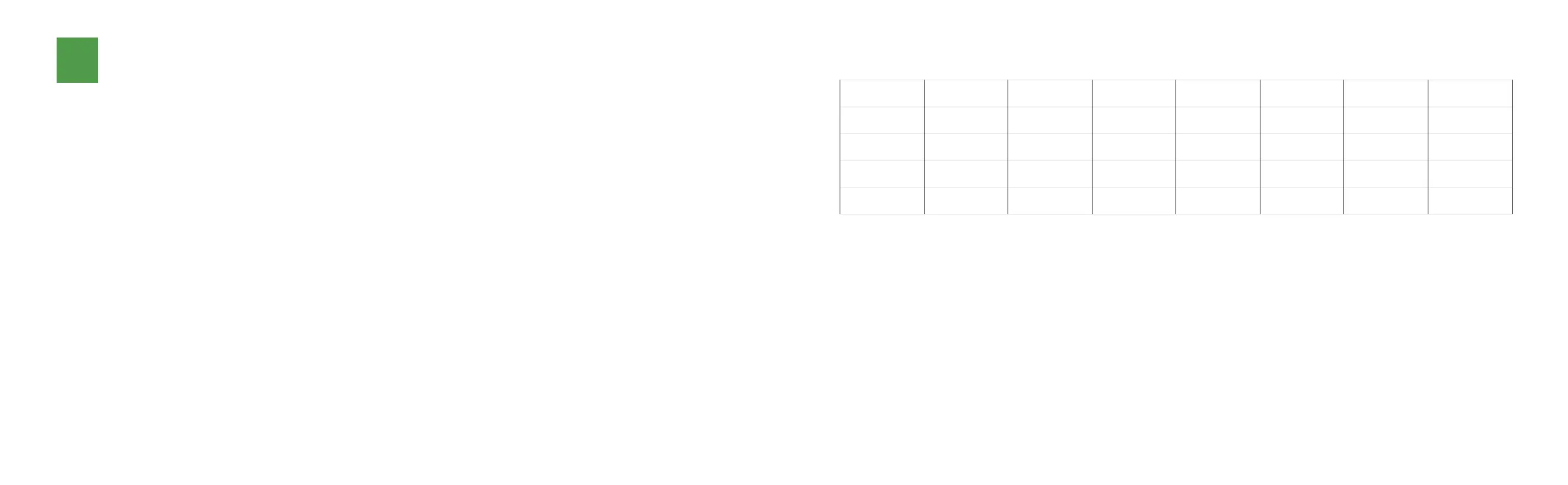

3. What is the printing temperature of the common materials?

4. The first layer can not normally stick to the platform.

5. The nozzle block

2.When the nozzle is too close or too far away from the hot bed after leveling?

Remove the leveling sensor, then adjust Z0,install the filament, then preheat the nozzle to 210 ° C,

preheat the hot bed to 60 ° C, feed filament and start printing.

Click once to move the nozzle 0.1, Z+ nozzle moves up, Z-head moves downwards, the software automatically saves

the value after clicking, and the value is saved until it is leveled again.

①. The nozzle is too far away from the hot bed,please refer to the nozzle is too close or too far

away from the hot bed

②. Select the Brim when attaching platform to slice,increasing the value of the line according

to your neded,Set hot bed temperature to 65°

Number Material Nozzle Hot bed Number Material Nozzle Hot bed

1 PLA 195-210 50-60 5 PVA 190-210 50-60

2 ABS 220-250 80-100 6 TPU 210-230 40-60

3 Nylon 200-220 50-60 7 WOOD 190-220 50-60

4 PETG 240-260 70-80 8 HIPS 230-250 60-80

①. Heating the sprinkler to 240 degrees, click fast extrusion.

②. Heating the sprinkler to 200 degrees, clean it with a sprinkler cleaning needle (hot, pay attention).

③. Replace a new sprinkler

Click during the printing process: Operate → More → Z+0.1 or Z-0.1

*

21

22

Loading...

Loading...