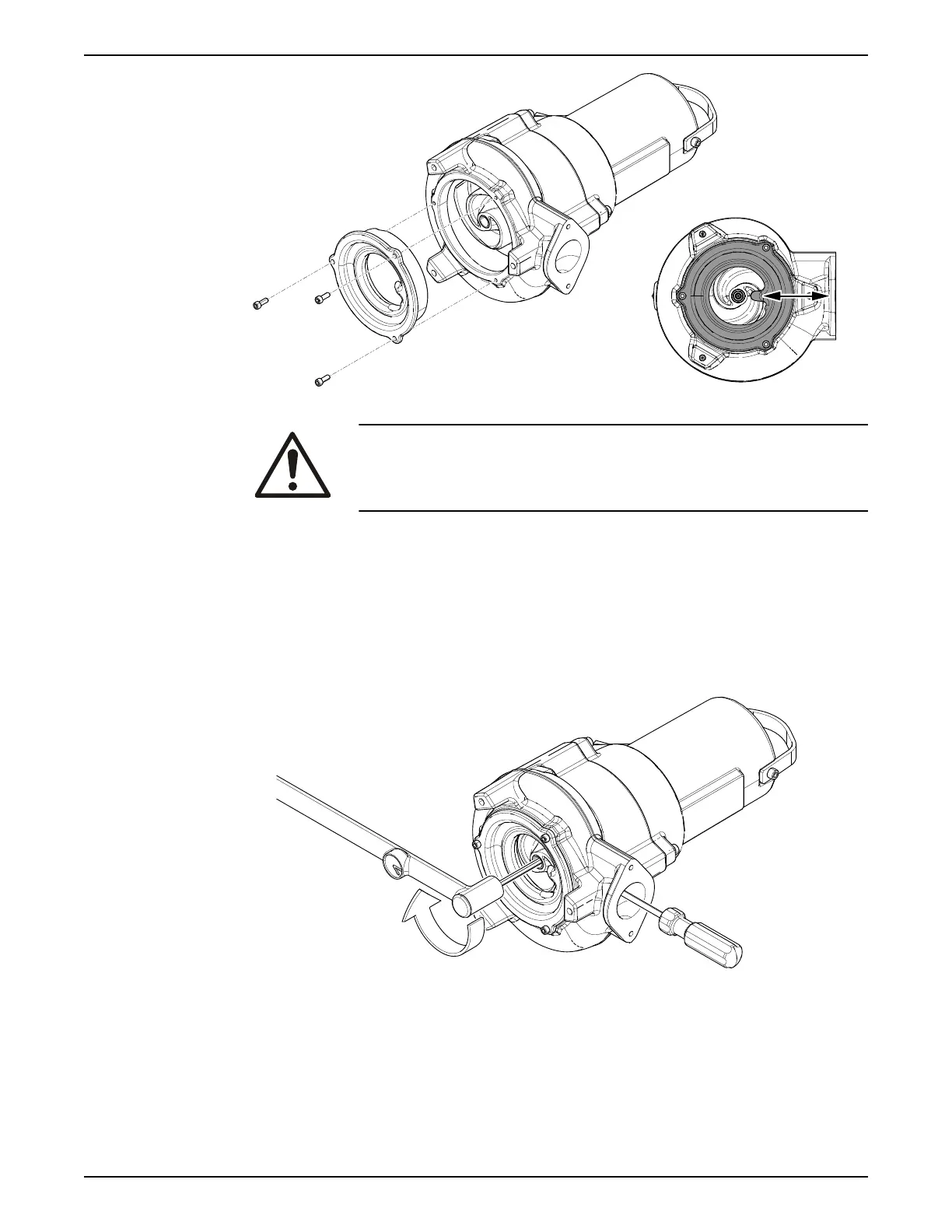

5. Check that the impeller can rotate freely.

WARNING: Crush Hazard

Beware of the pinch point hazard between the rotating impeller and the

guide pin.

6. Adjust the impeller:

a)

Turn the adjustment screw clockwise until the impeller touches the pump housing.

7. Fasten the impeller:

a) Fit the lubricated impeller screw.

b) Tighten the impeller screw.

For tightening torque, see Torque values on page 37.

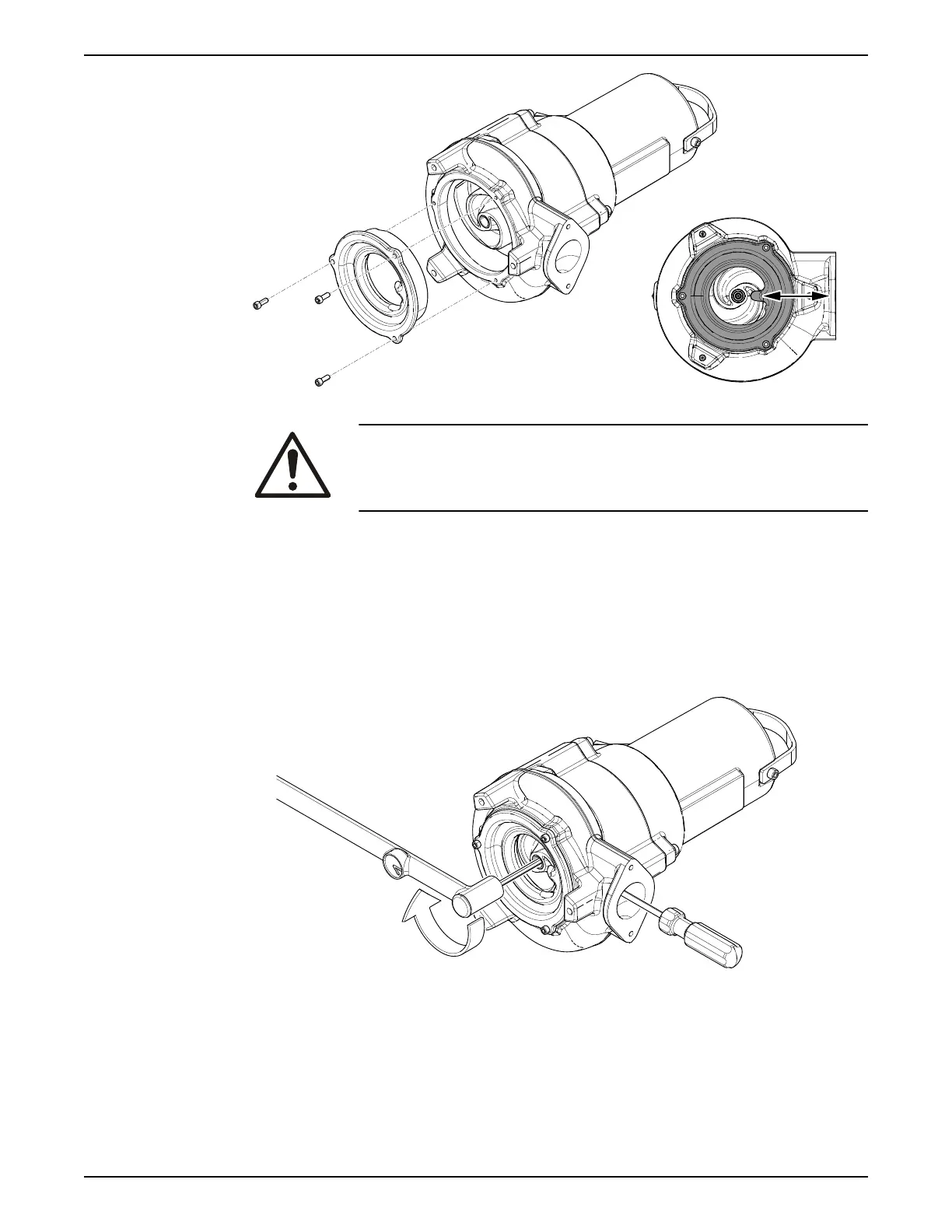

Prevent the impeller from rotating. Insert a screwdriver or similar through the pump

housing outlet.

c) Tighten the screw a further 1/8 turn (45°).

d)

Check that the impeller can rotate freely.

e) Check that the impeller moves freely up and down by pushing on it.

When the sleeve is released, it should be fully pushed out again. If the sleeve does

not move freely, or does not come fully out, then replace the impeller unit.

8. Check with a feeler gauge that the impeller clearance is 0.1 – 0.6 mm (0.004–0.02 in).

6 Maintenance

52 Flygt 3069 Installation, Operation, and Maintenance Manual

Loading...

Loading...