E 167 - GB - 6

28

Rue du Pré Neuf - 58440 MYENNES FRANCE

QUADRA

493 9021

493 9031

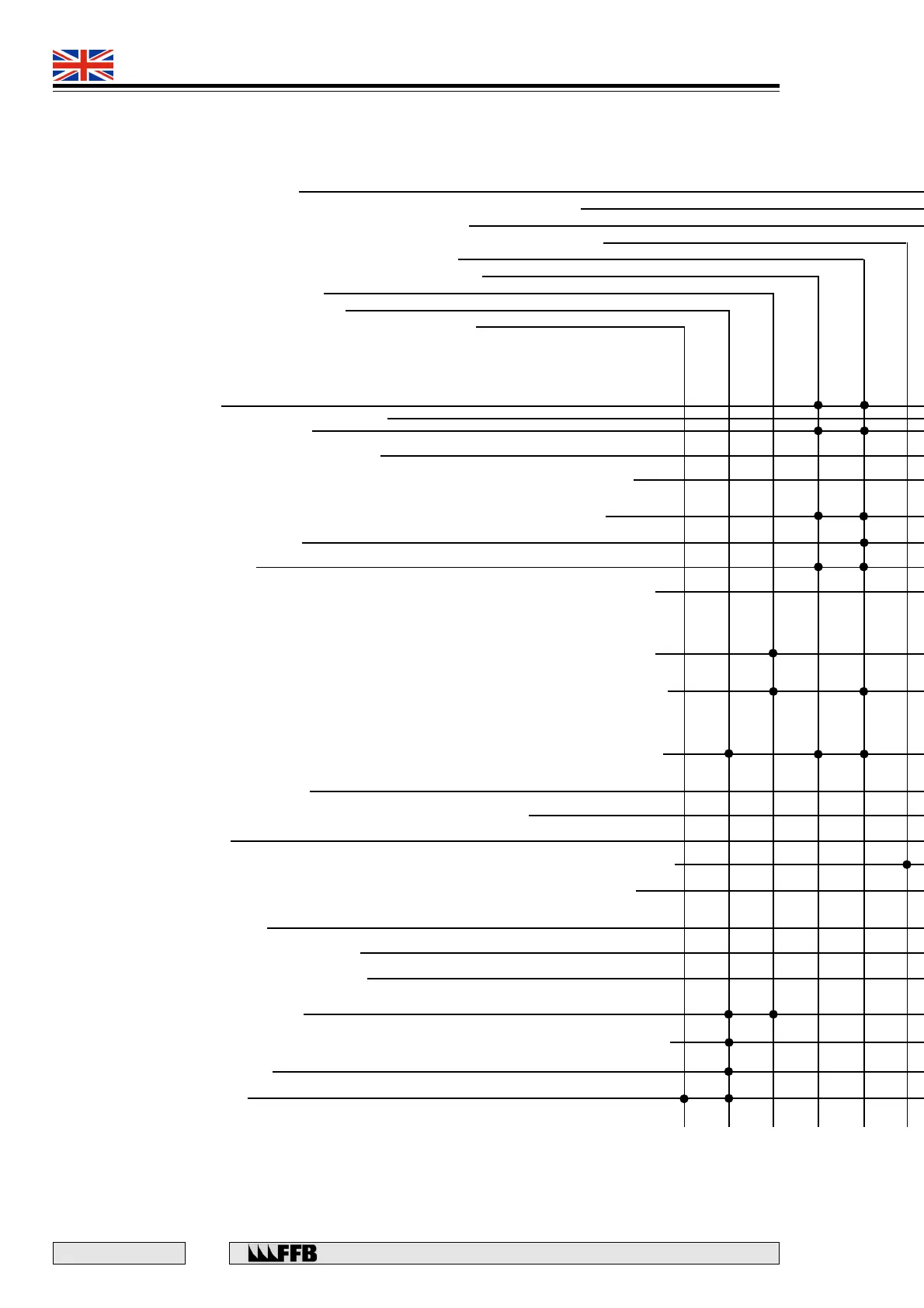

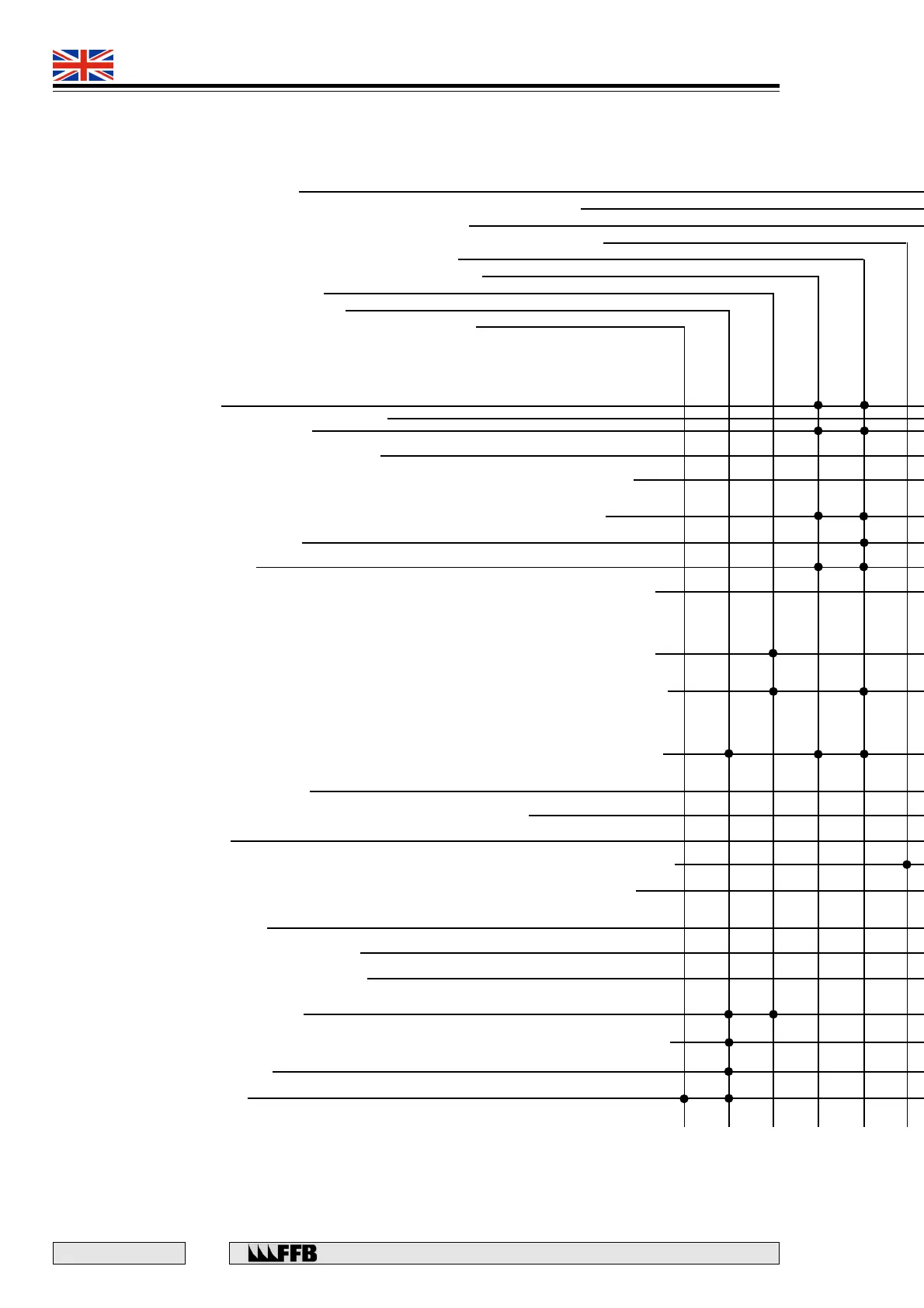

FAULT FINDING

FAULTS

On turning the control knob towards ‘RAISE’:

• The pump does not operate

• The pump works but the platform or the auxiliary raises slowly or not at all

• The platform or the auxiliary does not lift to its full height

• An unusual sound occurs when the deck or the auxiliary reaches its upper limit

• When the deck is being lowered, it stops unexpectedly

• When the auxiliary is being lowered, it stops unexpectedly

• Unable to start to lower the deck

• Unable to start to lower the auxiliary

• When the auxiliary is being lowered, it moves very slowly

CAUSES

1) No electricity supply to the lift due to

- a power cut

- the position of the emergency stop button

- damage to a fuse or the line

2) Tripping of the motor circuit breaker (emergency stop)

3) The platform is at ground level and poor adjustment of the wire ropes has allowed the rocker arm to

activate the safety switch.

4) The ‘LOWER’ lever has been moved too far which has caused the ram safety valve to function.

5) Failure of a platform support wire rope

6) Failure of the ram supply hose

7) The platform is resting on its latches. One or more of the wire rope safety switches have been activated

due to poor adjustment of the rocker retaining system clearance and the clearance of the switch.

8) A latch will not unlock and the functioning of the electrical safety device has caused the other latches to

fall back against the ladder racks.

9) An obstruction under the platform or the safety brake cam on one of the cross-member ends unexpectedly

operates.

10) A component in the electrical circuit is faulty (e.g. fuse, transformer, contactor coil, switch) or one of the

conductors is disconnected or poorly connected.

11) The vehicle is too heavy (unusual noise)

12) Due to work on the power supply line, the pump rotates in the wrong direction.

13) Lack of oil in the reservoir.

14) the upper limit switch has not been actuated by the cam fixed on the cross-member cheek plate or is faulty.

15) Poor sealing of the 'LOWER’ valve (lack of tension in the lever return spring, damage to its seat or

its needle).

16) The pressure relief valve is faulty.

17) The geared pump in the motor pump unit is worn.

18) The lift or auxiliary deck has reached its upper limit.

19) The three-way valve is poorly positioned

20) The cell is faulty or the beam is not returned due to an obstruction or the reflector is damaged or missing.

21) the solenoid valve does not work.

22) Hydraulic oil grade incorrect

Loading...

Loading...