19

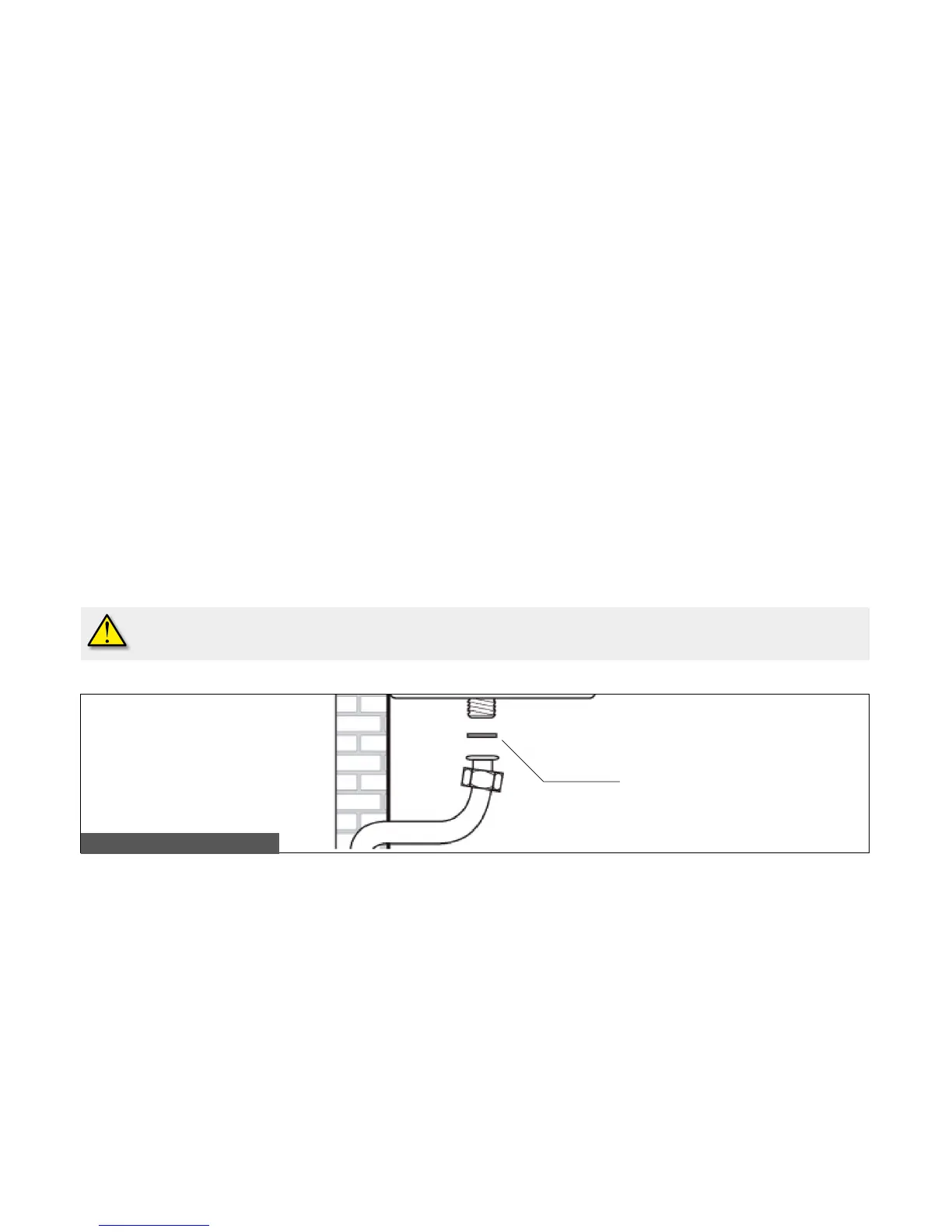

GASKET

Pic. 8 – Gas main connection

3.2.6 Checking combustion efficiency

In order to check combustion efficiency, turn no. 5 knob fully clockwise and completely open one or two domestic hot water taps so that the

boiler will operate at max. output.

In order to verify combustion efficiency the following measurements must be implemented:

• assess combustion air from the boiler installation room;

• assess ue gas temperature and CO2 from the special sampling port passing through the ue gas venting duct.

If sampling port is not present, it must be provided by the boiler operation and maintenance manager in compliance with the prevailing

regulations and standards.

Sampling port must be equipped with a special sealing and must be correctly closed after each reading.

Perform measurements while the boiler is operating at working temperature.

Once the above procedure is completed, close the domestic hot water taps and position no. 5 knob (pic. 1) to the desired setting.

3.2.7. Gas mains connection

Cross-section of gas supply pipe must be equal or greater than the boiler one. Cross-section size depends on its length, layout pattern, gas flow

rate. It is therefore to be sized accordingly.

Comply with installation standards enforced in the installation country. They are considered as an integral part of this booklet.

Remember that before operate an internal gas distribution system and before connecting it to a meter, it must be checked for leaks.

In order to perform a leak test, operate according to the following indication:

- The leak test is to be carried out before the pipes are covered. The leak test must not be carried out using flammable gas: use air or nitrogen

for this purpose.

- Once gas is in the pipes, leak test by a naked flame is forbidden. Use specific products available on the market.

When connecting a boiler to gas supply network the use of an appropriately sized and made gasket (pic. 8).

The boiler gas inlet thread configuration is not suitable for hemp, plastic tape or similarly made gaskets.

Loading...

Loading...