20

5.4 Time and Temperature Settings

For the best results, use the recommendedtime and temperature settings tested specifically

for use with the Form Cure.

Each material’s print settings are designed and refined to print parts successfully at optimal

speeds. Additional post-curing further improves the functional properties of the materials.

Post-curing exposes parts to light and heat and strengthens crosslinks in the polymer structure,

improving the parts’ strength, stiness, and temperature resistance. Due to the increased number

of bonds the material becomes more tightly packed and will shrink slightly. Each material’s print

settings are designed to account for the expected shrinkage during printing and post-curing.

Although using a higher temperature for post-curing results in a faster post-cure, a higher

temperature setting may also cause some materials to warp, depending on the part geometry

and features. When choosing to modify the recommended post-cure settings, the material must

be able to withstand the temperature and maintain a stable material structure.

Formlabs resins are designed for printing and post-curing with 405 nm light.

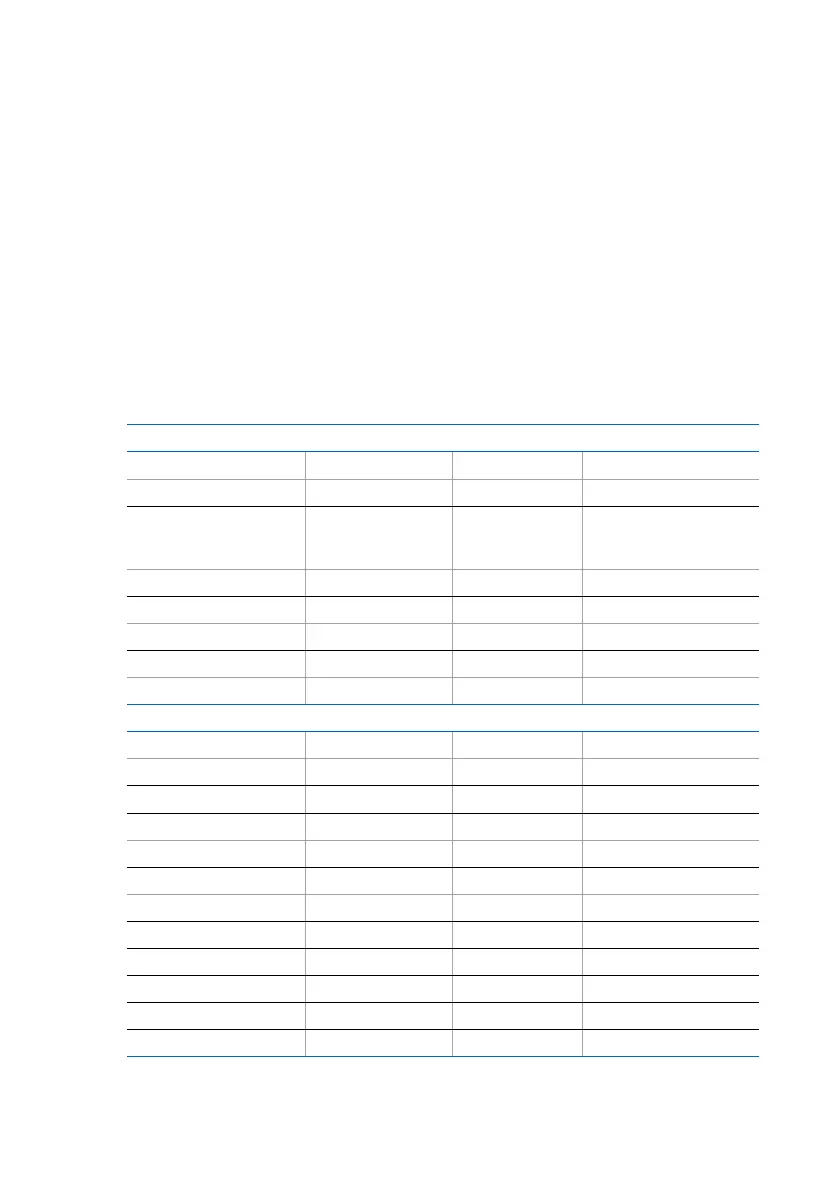

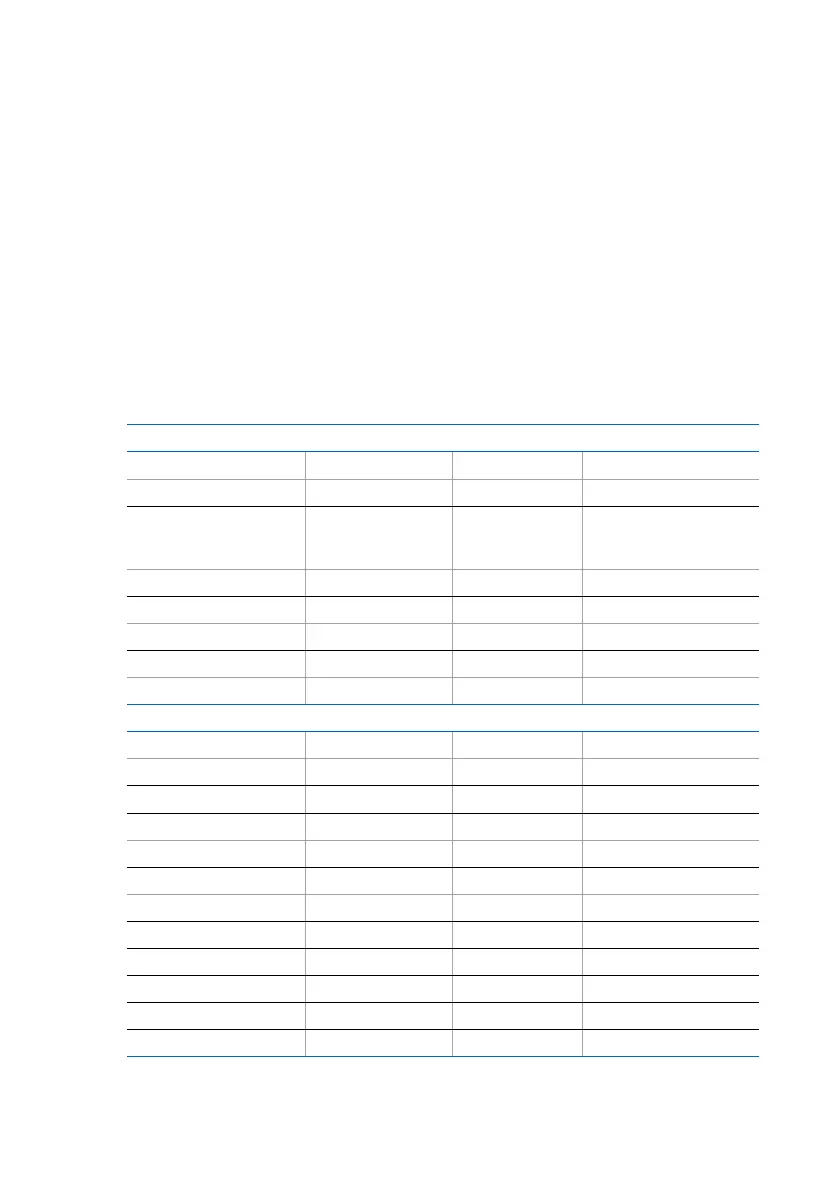

() (°C)

Clear Resin Recommended

1

15 60

Full Cure 30 60

Black Resin

White Resin

Grey Resin

Recommended

1

30 60

Full Cure 60 60

Color Resin Recommended

1

30 60

Full Cure 60 60

Draft Resin Better elongation 5 No heat

Better UTS 5 60

Tough Resin Recommended

1

60 60

Full Cure 120 60

Durable Resin Full Cure

2

60 60

Flexible Resin Recommended

1

15 60

Full Cure 60 60

High Temp Resin v1 Recommended

1

30 60

Full Cure 60 60

High Temp Resin v2 Recommended

3

120 80

Rigid Resin Full Cure

4

15 80

Grey Pro Resin Full Cure

4

15 80

Elastic Resin Full Cure 20 60

Ceramic Resin N/A

5

N/A N/A

Loading...

Loading...