10

Inline Pressure Boosting System

Plumbing Considerations for Priming Purposes:

The Inline 400 needs to be primed with water before it can function properly. There are two internal

non-return (check) valves built into the head of the unit that need to open during priming. This

requires that the priming water has an incoming pressure of 1.5 PSI minimum. This is especially

important if the application involves boosting water out of a shallow cistern. There are two simple

ways to accomplish this in the suction plumbing.

Inline 400 Priming:

Never run the pump dry. Fill the suction pipe, pump housing, and discharge piping completely with

water. A typical installation will be supplied by either a tank or a pressurized water source, creating

what is known as ooded suction condition

With the unit fully plumbed into the system, open the water supply valve and allow pressurized

water to ow through the unit. Place a small bucket under the Inline tank to capture water that is

expelled from the air-bleed during priming. With a small athead screwdriver, slowly open the air

bleed valve (located directly under the outlet) to allow air to exit the internal pump and tank. When

the valve stops sputtering and only a ne stream of water is being expelled, close the air bleed

valve. The unit is now primed and ready for operation.

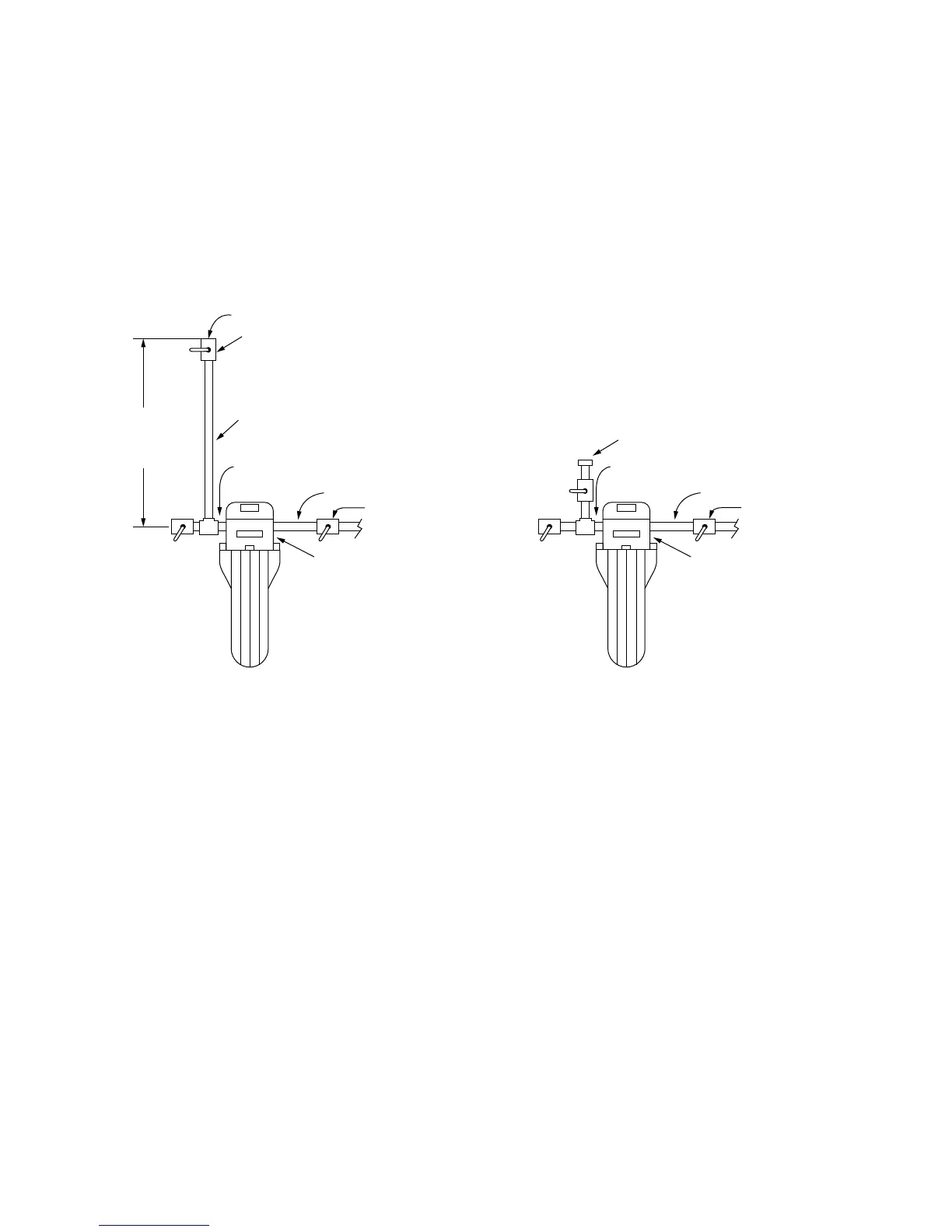

3’ MIN

ADD WATER FOR PRIMING HERE

SHUT-OFF VALVE

PRIMING TUBE

INLET

OUTLET LINE

OUTLET VALVE

AIR BLEED VALVE (VENT)

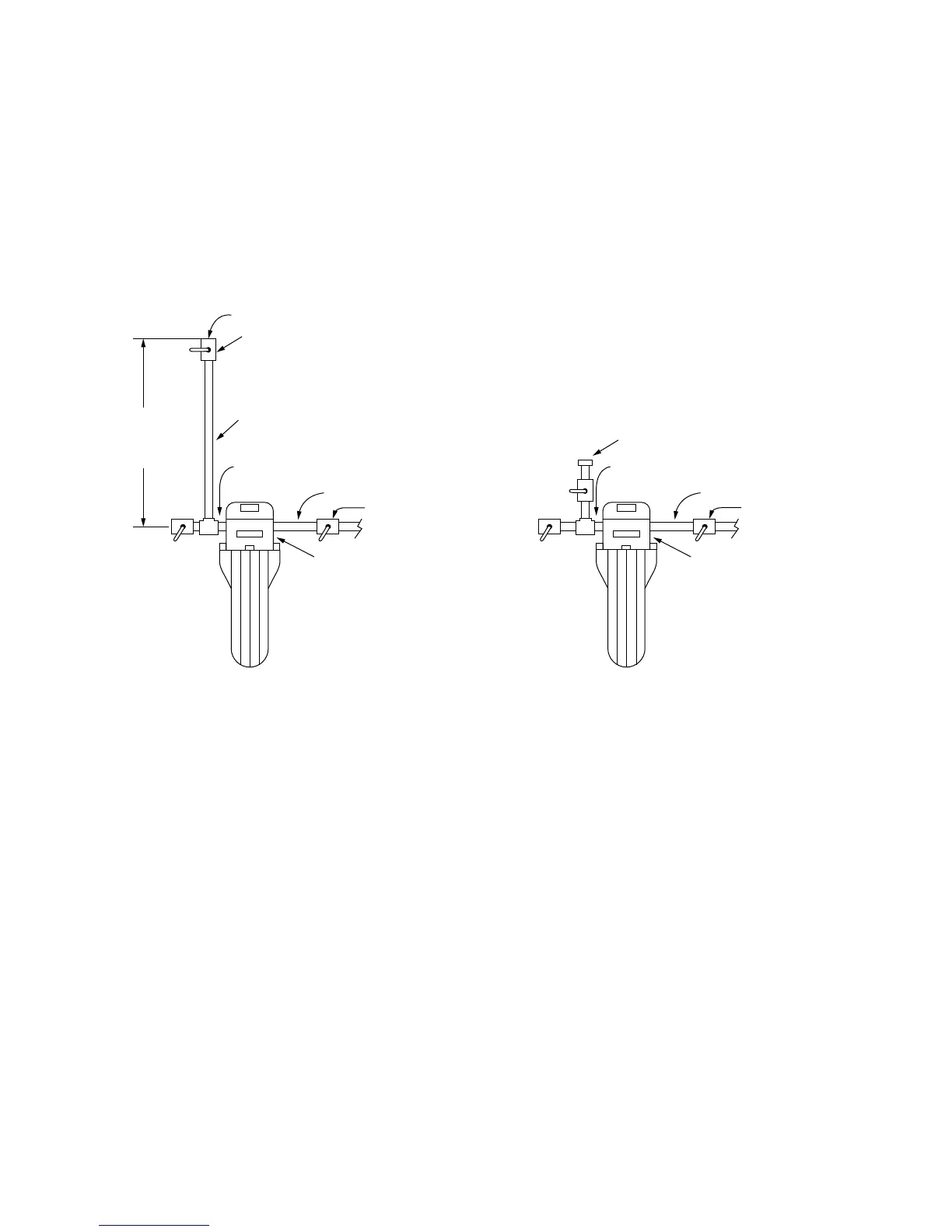

Garden Hose Fitting

INLET

OUTLET LINE

OUTLET VALVE

AIR BLEED VALVE (VENT)

PRIMING: 1.5PSI can be achieved on the

inlet by pouring water through a 3’ vertical

water column. Be sure to keep the inlet

valve closed and open the air-bleed valve

until all air is purged from unit.

PRIMING: Adequate inlet pressure/

ow can be achieved on the inlet by

connecting a garden hose to a tting

on the inlet side of the pump. Be sure

to keep the inlet valve closed , turn on

water supply, and open the air-bleed

valve until all air is purged from unit.

Loading...

Loading...