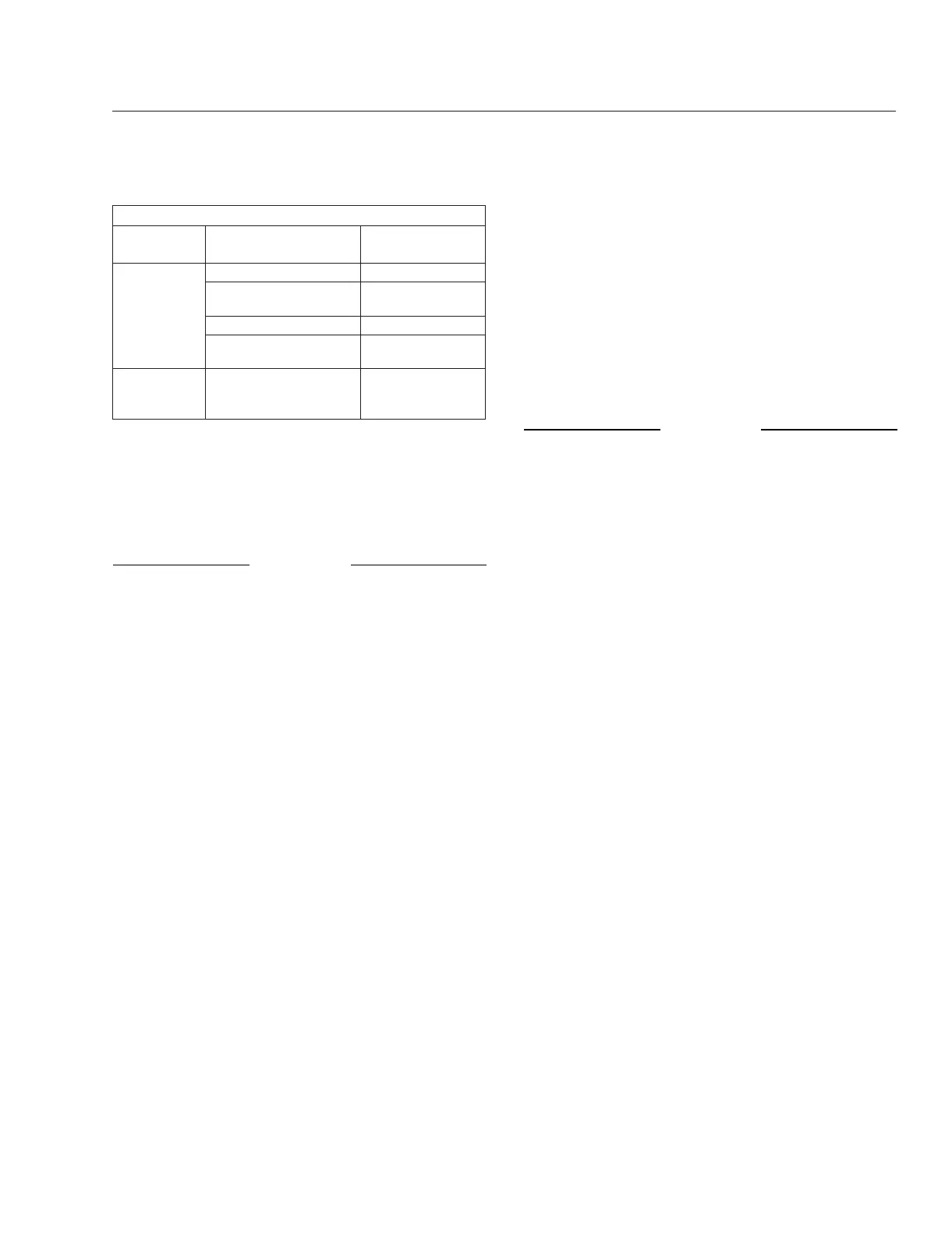

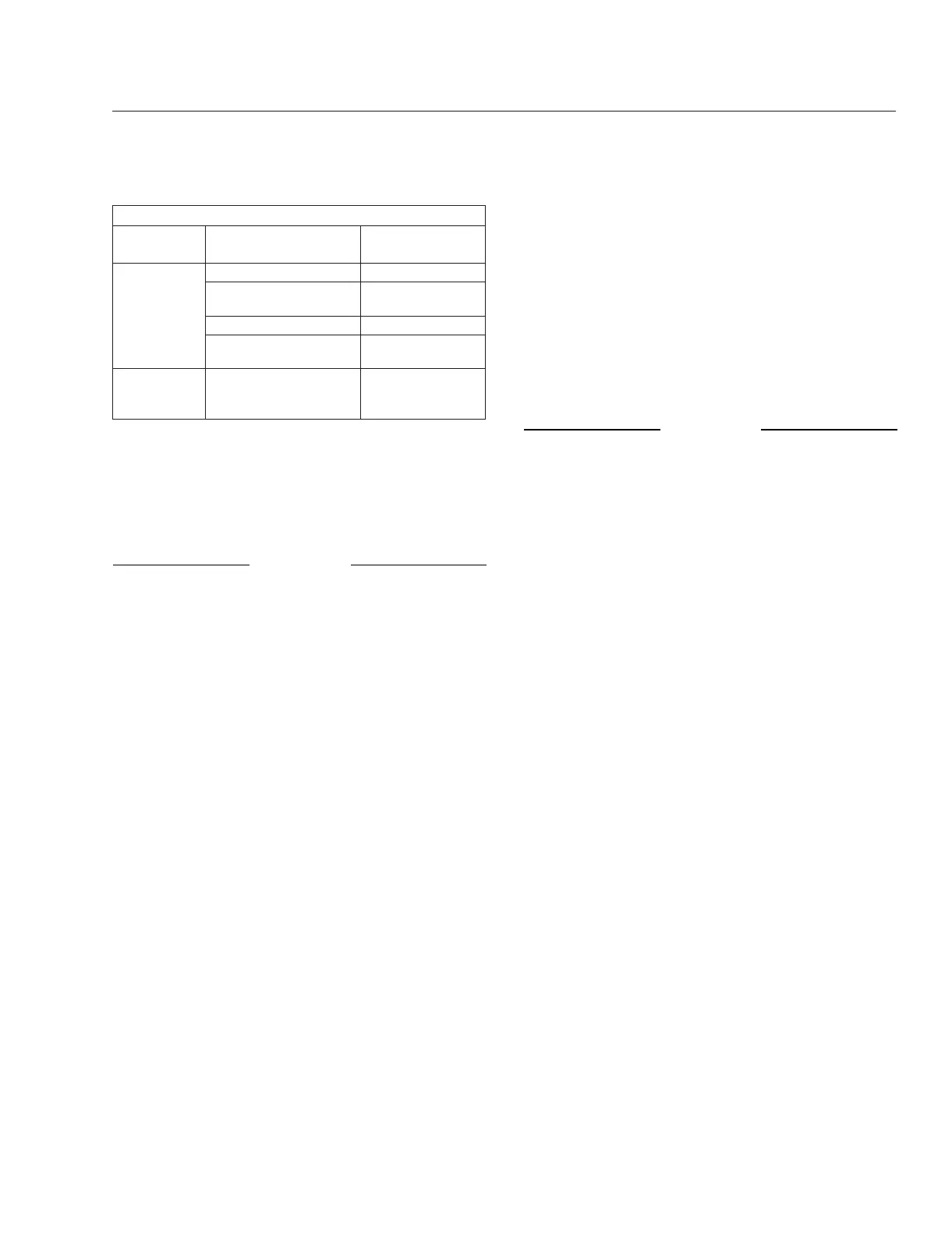

Approved Coolants

Engine Type Coolant Manufacturer

Coolant

Designation

*

Diesel

Old World Industries Fleet Charge®

Shell

Shell HD/N

Antifreeze

Texaco JC04 Antifreeze

Van Waters and

Rogers Ltd. (Canada)

Diesel Antifreeze

No. 6038

Propane Chevron

Chevron Delo

Antifreeze No.

275110

†

*

Freightliner-approved antifreeze must meet one of the following condi-

tions: A. Ethylene glycol solution that meets GM 6038–M Engineering

Standards. B. Ethylene glycol solution that has less than 0.1% anhydrous

sodium metasilicate and meets either GM 1825–M or GM 1899–M Engi-

neering Standards.

†

Chevron Delo coolant is approved for use in LPG engines only.

Table 15.1, Approved Coolants

NOTICE

Coolant must be filled to the full line of the surge

tank. Low coolant could result in engine over-

heating, which could cause engine damage.

4.

Inspect the radiator and charge air cooler.

4.1

Inspect the radiator and charge air cooler

for clogged fins. Use compressed air or

water directed from the fan side of the

core to backflush any material restricting

airflow.

4.2

Inspect the radiator and charge air cooler

for damage and accumulated debris.

Straighten bent or damaged fins to permit

airflow across all areas of the cores.

NOTE: When traveling through areas of high

insect concentration, it may be necessary to

clean the exterior of the radiator or the

charge air cooler core as often as every 200

miles (320 km).

4.3

Also inspect and clean the condenser. If

clogged, the condenser can restrict airflow

through the radiator.

4.4

Check the radiator for leaks. If leaks are

found, have the radiator repaired or re-

placed. See Group 20 of the S2 Chassis

Workshop Manual for instructions, or take

the vehicle to an authorized Freightliner

dealer.

5.

Inspect the engine and chassis wiring.

Check for loose wiring, chafed insulation, and

damaged or loose hold-down clamps. Tighten

loose wires or hold-down clamps; replace dam-

aged wiring or clamps.

6.

Inspect the air intake system for leaks or dam-

age.

NOTICE

Failure to maintain a sealed air intake system

could allow entry of dirt and contaminants into

the engine. This could adversely affect engine

performance and result in engine damage.

6.1

Check the intake-air restriction indicator.

6.2

Replace the primary filter element in the

air cleaner if the yellow signal stays

locked at 20 inH

2

O for Mercedes-Benz

engines and 25 inH

2

O for Cummins ISB

engines. See Group 09 of the S2 Chassis

Workshop Manual for filter element re-

placement instructions, or take the vehicle

to an authorized Freightliner dealer. See

Fig. 15.2.

NOTE: After replacing the filter element,

reset the restriction indicator by pressing the

rubber reset button.

6.3

Inspect the secondary or safety filter ele-

ment in the air cleaner when replacing the

primary element, and replace it when

clogged or dirty. This element should be

replaced with every third primary element

replacement.

6.4

Check the engine air intake piping from

the air cleaner to the engine intake. In-

spect the piping for loose connections,

cracks, torn or collapsed hoses, punc-

tures, and other damage. Tighten loose

connections, and have damaged compo-

nents replaced. Make sure the piping sys-

tem is airtight so that all intake air passes

through the air cleaner.

Pre- and Post-Trip Inspections and Maintenance

15.2

Loading...

Loading...