Safety Precautions

DANGER

When working on the vehicle, shut down the en-

gine, set the parking brake, and chock the tires.

Before working under the vehicle, always place

jack stands under the frame rails to ensure the

vehicle can not drop. Failure to follow these

steps could result in serious personal injury or

death.

Daily Pretrip Inspection and

Maintenance Procedures

Whenever equipment requires adjustment, replace-

ment, and/or repair, see the S2 Chassis Workshop

Manual for procedures and specifications. Specific

references to the manual will be found where appro-

priate.

1.

Drain the brake system air reservoirs (reservoirs

without automatic drain valves only).

Water and oil normally enter the air reservoir in

the form of vapor because of the heat generated

during compression. After the water and oil con-

dense, drain the resulting emulsion as follows:

1.1

Open the wet tank valve. The drain cock

or pull chain drain is located on the for-

ward end of the supply air reservoir, which

is connected directly to the air compres-

sor. Block the valve open.

WARNING

When draining the air reservoir, do not look into

the air jets or direct them toward anyone. Dirt or

sludge particles may be in the airstream and

could cause injury.

1.2

Exhaust the remaining air and moisture

from the system by opening the drain

cocks on the bottoms of the remaining air

reservoirs. Block the valves open.

1.3

Water and oil emulsion often form pockets

that will not drain while compressed air is

in the reservoirs. Because of these pock-

ets, leave the valves blocked open during

the first part of the pretrip inspection.

1.4

If the drained water is cloudy or oily, it

may indicate a problem with the compres-

sor. If oil is allowed to contaminate the air

dryer, it will not remove the water from the

air brake system, which could adversely

affect braking.

2.

Check the fluid level in the windshield washer

reservoir.

Add washer fluid as needed. Unscrew the cap to

add fluid.

WARNING

Washer fluids may be flammable and poisonous.

Do not expose washer fluid to an open flame or

any burning material, such as a cigarette. Always

comply with the washer fluid manufacturer’s rec-

ommended safety precautions.

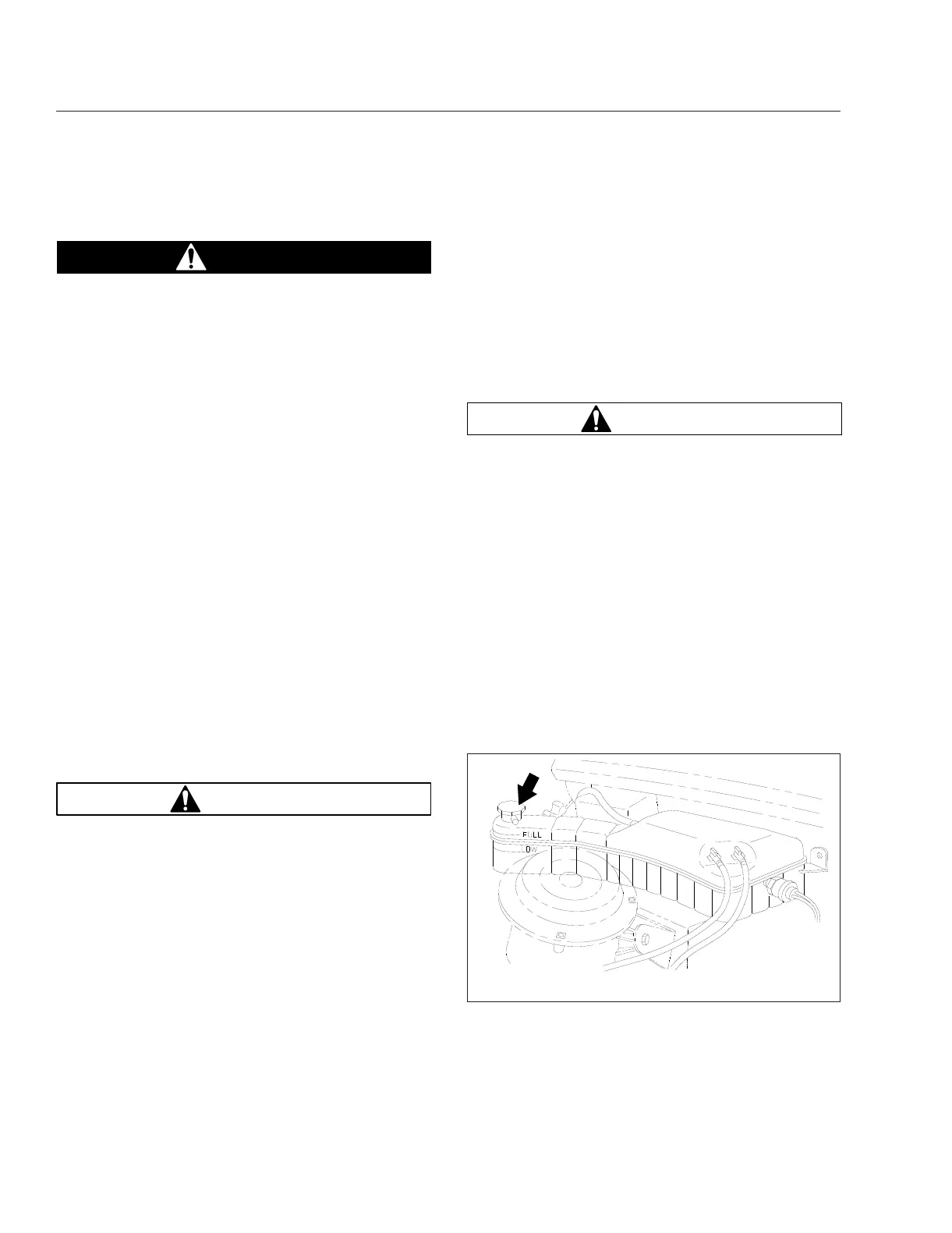

3.

Check the coolant level in the surge tank.

See

Fig. 15.1. If the coolant is low, add a 50/50

mixture of water and the type of antifreeze cur-

rently installed in the vehicle. For a list of ap-

proved coolants for both diesel and liquid pro-

pane gas (LPG) engines, see

Table 15.1. Fill the

surge tank with coolant to the MAX line when the

tank is cool. If the surge tank was empty, start

the engine after refilling and check the level

again when the engine is at operating

temperature.

11/02/2001

f820382

Add coolant here (arrow).

Fig. 15.1, Coolant Level Checking

Pre- and Post-Trip Inspections and Maintenance

15.1

Loading...

Loading...