131 PB

TROUBLESHOOTING

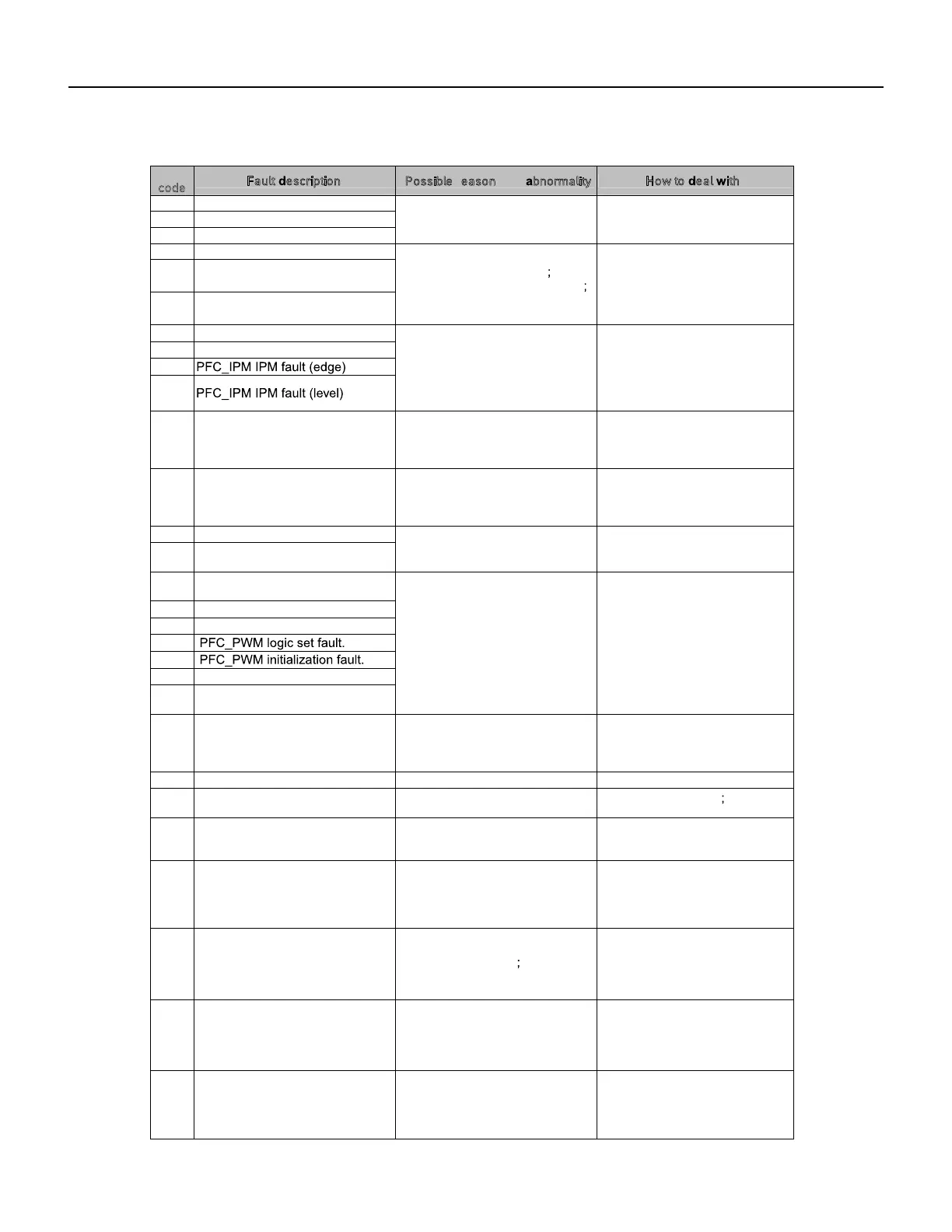

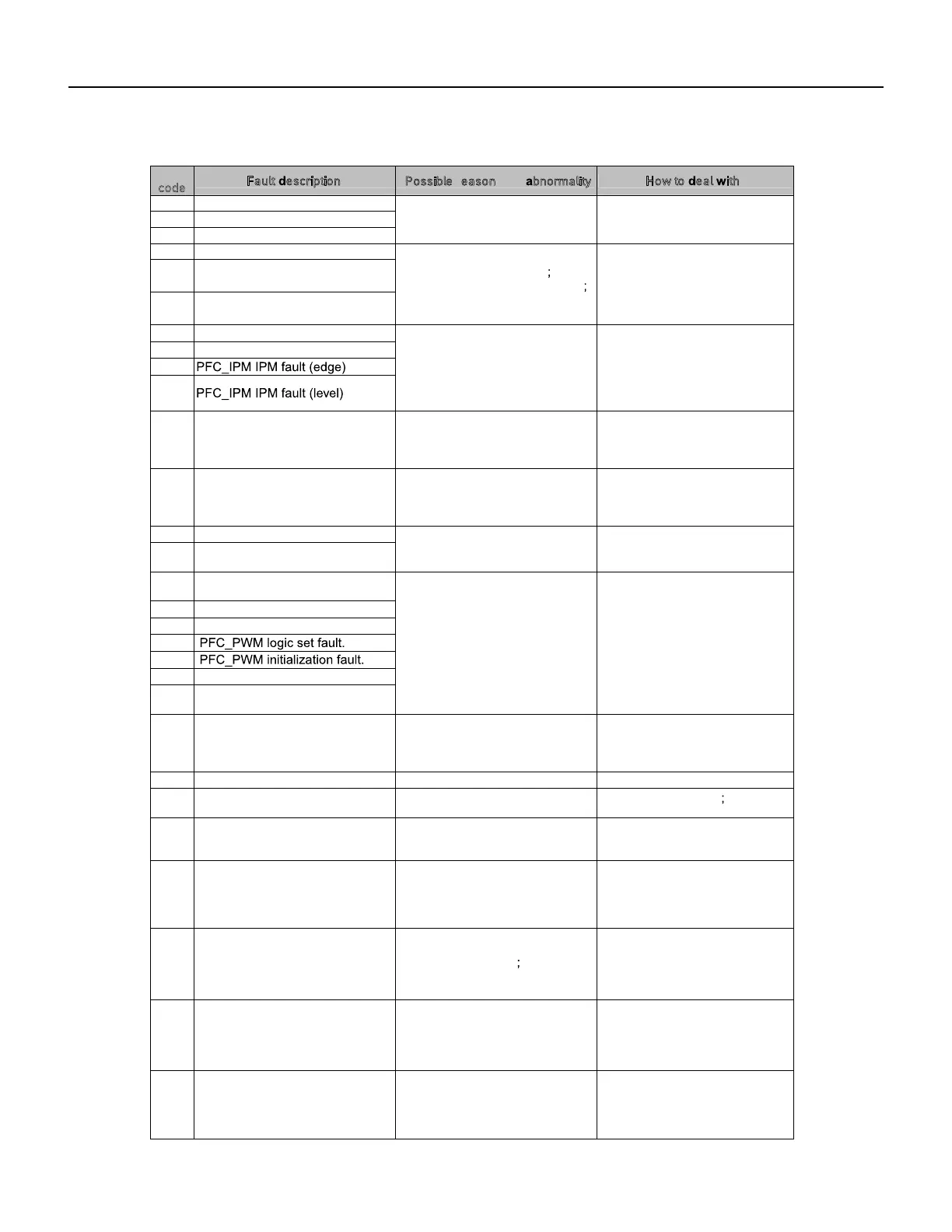

Drive fault code (3.0/3.5HP)

code

Fault escription

Possible reasons for bnormality

How to eal ith

1 Inverter DC voltage overload fault

1. Power supply input is too high

or too low;

2. Driver board fault.

2

1. Check power supply;

2. Cha nge driver board.

Inverter DC low voltage fault

3 Inverter AC current overload fault

4 Out-of-step detection

Loss phase detection fault (speed

1. Compress or phas e lost

2. Bad driver board components

3. The compress or insulation fault.

5

1. Check compre ssor wire

connect ion;

2. Cha nge the driver board ;

3. Cha nge compressor.

pulsation)

6

7

Loss phase detection fault (current

imbalance)

Inverter IPM fault (edge)

overload;

2.

1. System overload or current

3.

4. The compress or insulation fault.

Driver board fault.

Compress or oil shortage,

serious wear of crankshaft ;

8 Inverter IPM fault (level)

1. Check the system.

2. Cha nge the driver board;

3. Cha nge the compressor;

4. Cha nge the compressor.

9

10

11 PFC power detection of failure

1. The power supply is not stable;

2. Instantaneous power off;

3. Driver board failure.

12

1. Chec k the power supply.

2. No need to deal with .

3. Cha nge the driver board.

PFC overload current detection of

failure.

1. System overload, current is

too high;

2. Driver board fails;

3. PFC fails.

13

1.Check the system;

2.Change the driver board;

3.Change the PFC.

DC voltage detected abnormal .

1. Input voltage is too high or too

low;

2. Driver board fails.

14

1. Chec k the power supply;

2. Cha nge the driver board.

15

PFC LOW voltage detected

failure.

AD offset abnormal detected

failure.

Driver board fails.

Change the driver board.

16

Inverter PWM logic set fault.

17

18

Inverter PWM initialization failure

19

20

Temperature abnormal.

21

22

Shunt resistance unbalance

adjustment fault

Communicati on failure.

1. Communicati on wire connect ion

is not proper;

2. Driver board fails;

3. Contro l board fails.

23

1. Chec k the wiring;

2. Change the driver board ;

3. Change the control board.

Motor parameters setting of failure Initialization is abnormal.

25

Reset the power supply.

EE data abnormal

Driver board EEPROM is abnormal

1. Change EEPROM

2. Change the driver board.

26 DC voltage mutation error

1. Power input chang es suddenly

2. Driver board fails.

27

1.Chec k power supply, to provide

stable power supply ;

2.Change driver board.

D axis current control error

1. System overload , phas e current

is too high;

2. Driver board fails.

28 Q axis current control error

1. Chec k system to see if it works

normally.

2. Chec k stop valve to see if it is

open;

3. Change the driver board.

29

1. System overload s, phas e

current is too high

2. Driver board fails.

1.

2.

Saturation error of d axis current

control integral

System overload suddenly;

Compress or parameter is

not suitable;

3. Driver board fails.

30

Saturation error of q axis current

control integral

1. System overload suddenly;

2. Compress or parameter is

not suitable;

3. Driver board fails.

1. Chec k system to see if it works

normally.

2. Chec k stop valve to see if it is

open;

3. Change the driver board.

1. Chec k system to see if it works

normally.

2. Chec k stop valve to see if it is

open;

3. Change the driver board.

1. Chec k system to see if it works

normally.

2. Chec k stop valve to see if it is

open;

3. Change the driver board.

Loading...

Loading...