Do you have a question about the Fronius KD 7000 D-11 and is the answer not in the manual?

Covers general safety, operator qualifications, and device handling procedures.

Defines intended use, improper use, and responsibilities regarding the welding equipment.

Specifies operating and storage conditions for the device, including temperature and humidity.

Details the responsibilities and qualifications required for the device operator.

Outlines the duties and training required for all personnel involved with the device.

Addresses requirements and precautions for connecting the device to the mains supply.

Lists risks to users and bystanders, including sparks, arc radiation, and electromagnetic fields.

Provides information on the sound power level generated by the device during operation.

Discusses hazards from welding fumes and gases, and necessary ventilation measures.

Warns about fire and explosion risks associated with flying sparks during welding.

Details hazards associated with mains and welding currents, including electrocution risks.

Explains consequences of meandering currents and how to prevent them.

Covers device emission classes and measures to avoid electromagnetic interference.

Advises on health risks from electromagnetic fields and necessary precautions.

Identifies specific risks such as moving parts, hot components, and welding wire.

Details quality requirements for shielding gas and safe handling of cylinders.

Provides safety measures for device installation location and during transport.

Outlines safety measures to be followed during normal operation of the device.

Covers procedures for initial setup, ongoing maintenance, and repairs.

Recommends frequency and procedures for safety inspections and calibration.

Instructs on the proper disposal of the device according to regulations.

Explains device markings like CE and CSA, and compliance directives.

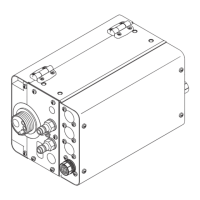

Describes the design, capabilities, and compatibility of the cold wire feeder.

Lists the types of welding processes and applications for which the device is suited.

Explains the importance and handling of safety symbols on the device rating plate.

Notes on firmware updates and illustration differences within the manual.

Identifies and details the various controls, connections, and mechanical parts of the unit.

Provides instructions for securely mounting the cold wire feeder onto the power source.

General steps for connecting the wire feeder to the power source.

Details connection when gas pipe is inside the interconnecting hosepack.

Details connection when gas pipe is separate from the interconnecting hosepack.

Guides on how to attach the welding torch to the system.

Explains how to insert or replace feed rollers for optimal wire feeding.

Describes how to safely insert standard wire spools and basket-type spools.

Details the steps for threading the welding wire through the feeder.

Instructs on setting the correct contact pressure for the wire electrode.

Explains how to adjust the wire spool brake for proper tension and stopping.

Covers fitting the hose for protecting the external welding wire.

Provides step-by-step instructions for calibrating the push-pull wire feeding unit.

Lists error codes encountered during push-pull calibration and their remedies.

Details error codes related to the cold wire feeder and their causes/solutions.

Lists error codes for the digital gas control option and troubleshooting steps.

Outlines regular checks, cleaning, and maintenance tasks for the wire feeder.

Guides on environmentally sound disposal of the equipment.

Lists key technical data, dimensions, voltage, current, and operating parameters.

| Number of MPPTs | 2 |

|---|---|

| Max. output current | 30.4 A |

| AC voltage range | 180 - 280 V |

| Frequency | 50 / 60 Hz |

| THD | < 3 % |

| Number of MPP trackers | 2 |

| Max. apparent AC power | 7 kVA |

| AC nominal power | 7 kW |

| Max. efficiency | 98.3% |

| Input Voltage Range | 200-1000 V |

| DC input voltage range | 200-1000 V |