Hotstart function To obtain optimum welding results, it will sometimes be necessary to adjust the hotstart

function.

Benefits

- Improved ignition, even when using electrodes with poor ignition properties

- Better fusion of the base material in the start-up phase, meaning fewer cold-shut

defects

- Largely prevents slag inclusions

For details on setting the available welding parameters, please refer to the "Rod elect.

setup 2nd" section.

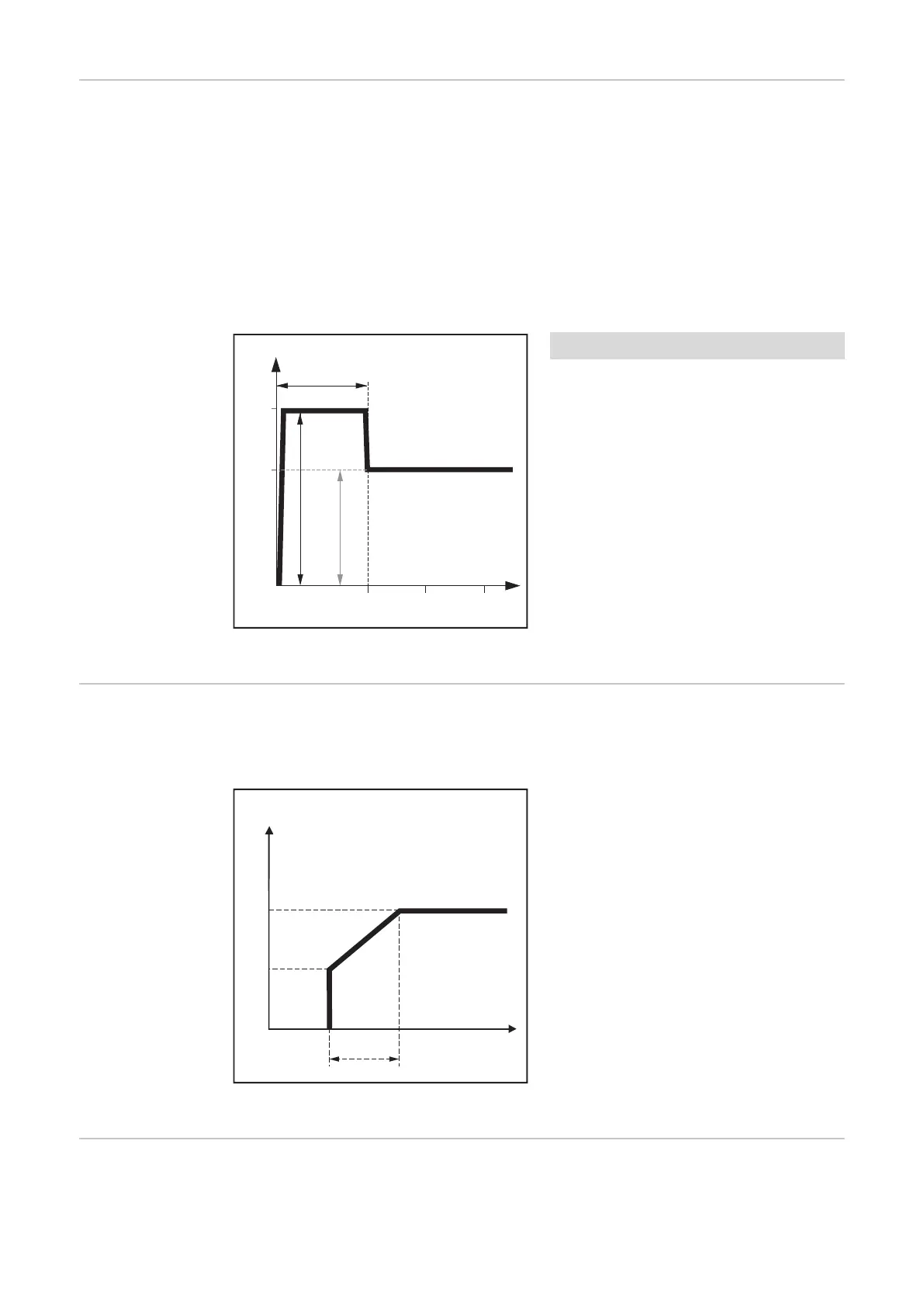

I (A)

t (s)

0,5 1 1,5

Hti

I

1

HCU

100

150

Example of hotstart function

Legend

Hti Hot-current time, 0-2 s, factory

setting: 0.5 s

HCU HotStart current, 0-200%,

factory setting 150%

I

1

Main current = set welding cur-

rent

Function:

during the specified hot-current time (Hti),

the welding current I

1

is increased to the

HotStart current HCU.

To activate the hotstart function, the Hot-

Start current HCU must be > 100.

Starting current

< 100 %

(SoftStart)

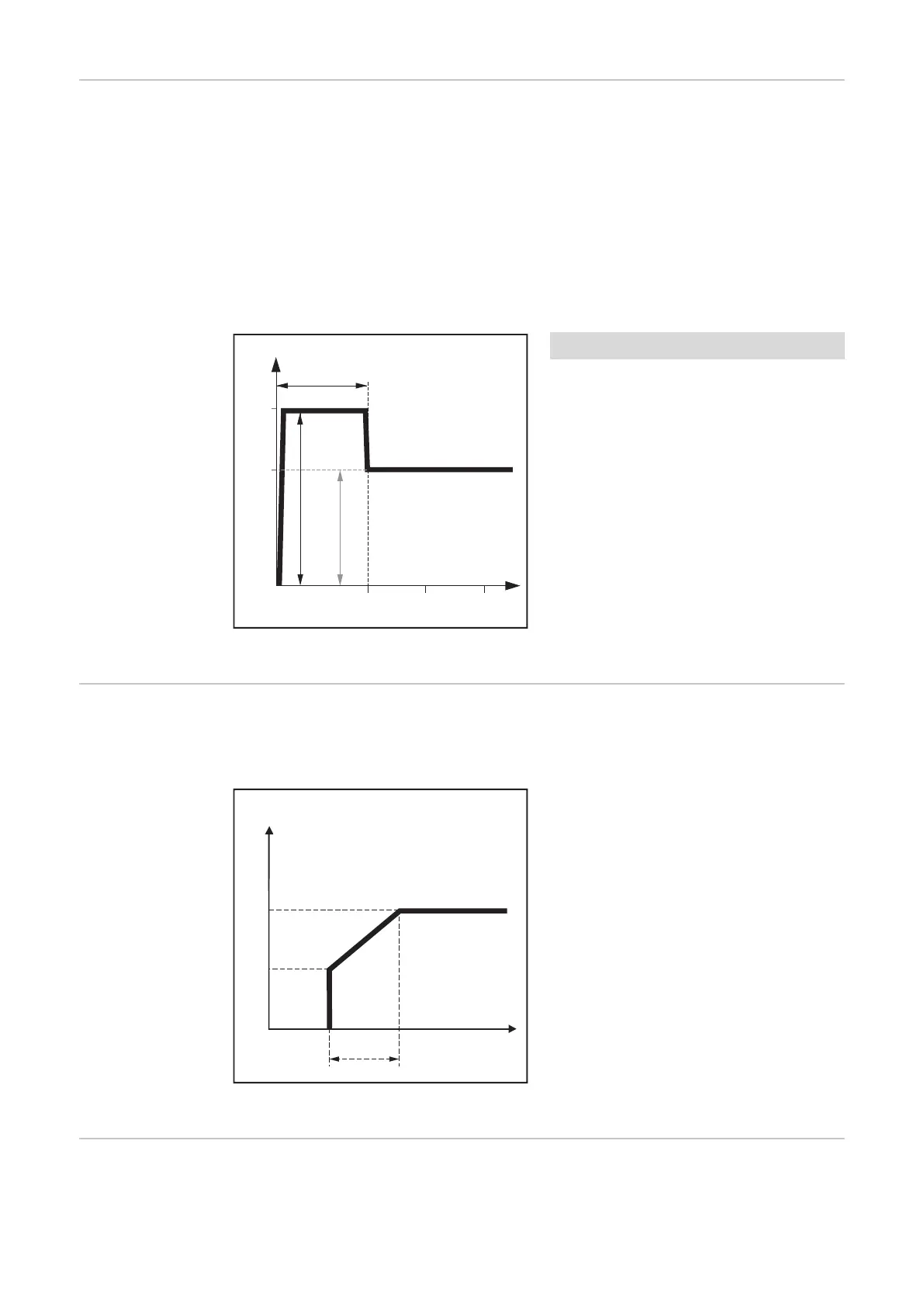

A starting current < 100% (SoftStart) is intended for basic electrodes. Ignition takes place

at a low welding current. Once the arc is stable, the welding current continues to rise

until it reaches the welding current command value.

Example with a starting current < 100% (SoftStart)

Benefits:

- Improved ignition properties for elec-

trodes that ignite at low welding cur-

rents

- Largely prevents slag inclusions

- Reduces welding spatter

(1) Starting current

(2) Starting current time

(3) Main current

The starting current time is set in the rod

electrodes menu.

Anti-stick func-

tion

As the arc becomes shorter, the welding voltage may drop so far that the rod electrode

will tend to stick. This may also cause the rod electrode to burn out.

68

Loading...

Loading...